Twapster said:https://www.prospectingaustralia.com/forum/img/member-images/1582/1384430175_highbaker1a.jpg

https://www.prospectingaustralia.com/forum/img/member-images/1582/1384430257_highbaker1b.jpg

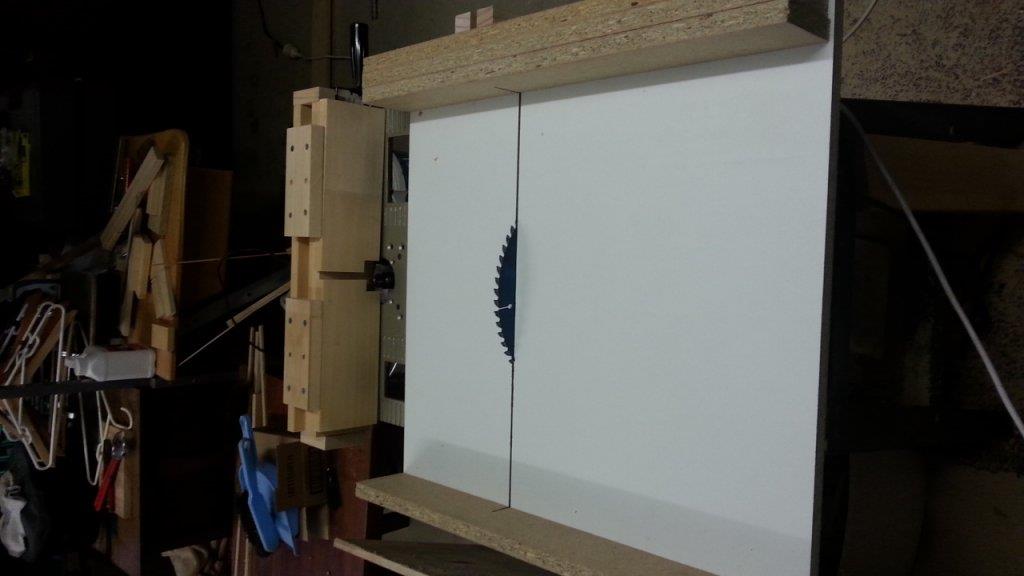

Tray for higbanker cut and folded. Let the braising begin.

Peter

what do you mean brazing ?

are you going to try to weld it with oxy acetylene ?

tig welding is more successful if you have a local welder who has one and shouldnt cost much