hey digger you might be right mate I could only find 65mm hose wanted 76mm no irrigation suppliers would cut me a few metres I jad to buy a lenght which was $86 ill test it tommorrow by connecting the box directly to the blower

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wooden Dry washer

- Thread starter G0lddigg@

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Golddigg that is an inspiring build.

Thanks for posting

Thanks for posting

Golddigg Another thing I think you fan is way to heavy,perhaps a computer fan might be better,put the counter weights on the blades

Just to get you by perhaps air condition duct might be the go.

you do not need heavy hose,purple pig sells all kind of hose,the stuff that they use has got a wire in it,and which is light.

These projects take time,the material you need is sometimes sitting on the shelf at Bunnings.

Just to get you by perhaps air condition duct might be the go.

you do not need heavy hose,purple pig sells all kind of hose,the stuff that they use has got a wire in it,and which is light.

These projects take time,the material you need is sometimes sitting on the shelf at Bunnings.

yeh ive been looking for hose for a while mate im in the hardware at least everyday nothing there but what I bought. might try a heating joint for some hose good call.

re the counterbalance it spins quite well and shakes the box I cant see any issue with it tye problem im having is not enought air pressure. even with the counterbalance removed tgeres not enough air to blow the fines very well. I built it based on what ive seen in the market they seem quite bulky

mate have you posted any pics of your ball mill

re the counterbalance it spins quite well and shakes the box I cant see any issue with it tye problem im having is not enought air pressure. even with the counterbalance removed tgeres not enough air to blow the fines very well. I built it based on what ive seen in the market they seem quite bulky

mate have you posted any pics of your ball mill

- Joined

- Aug 6, 2013

- Messages

- 323

- Reaction score

- 102

G0lddigg@ said:tye problem im having is not enought air pressure. even with the counterbalance removed tgeres not enough air to blow the fines very well.

hi mate

did you load your bottom box right up? as the dry blowers don't work real well until there is dirt completely covering your material to build up pressure in the bottom box.

if the cloth is only half covered the air will take the path of least resistance (where there's no dirt) and it don't do much, even with a big blower

I'm off to amhurst this weekend for a club outing and if it don't rain between now and then I was thinking about taking my blower over to get some concentrates to play with my gold wheel at home.

so if your free and want to hook up my 151 blower to your's to see if a bigger blower would work your welcome to come over and give it ago.

let me know if you want to and i'll e-mail you a map of where we'll be.

regards tm

that might just work mate id love to see the 151 in action anyway  I think I can get down on the saturday. sunday the missus has me booked in for the balan autumn festival

I think I can get down on the saturday. sunday the missus has me booked in for the balan autumn festival

thedigger said:Hi Golddigg

No not yet,made it last year,used a 9kg gas bottle,gear box and motor under the bench,lucky got the steel balls from a friend in the west,the balls are about 30mm.

Regards Thedigger

mate if you ever need balls I know a god hill in ballarat thats loaded with cannon balls I got about 22 in an hour last time I went out theyrange from 30mm 80mm in size

Golddigg,

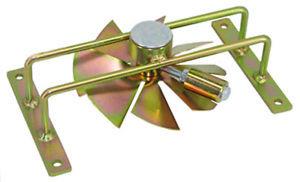

Maybe something you can try. At the moment it appears you have a direct blast of air into the box and a counterweight for vibration.

What you need is interrupted air supply, eg: bellows type dry blower is interrupted.

Before you spend more money it would be worth your while experimenting with making your air supply "flutter." ie: Difficult to explain, but here goes.

Cut a round metal disc to the inside diameter of the blower delivery, curve the ends so the blown air will make it spin on a shaft.

Drill holes through the pipe slide a rod through then tack weld it to the disc.

When the blower delivers air it will flutter with the spinning disc and help move your fines down the riffle box.

Maybe someone here can draw a diagram to explain it clearly.

Maybe something you can try. At the moment it appears you have a direct blast of air into the box and a counterweight for vibration.

What you need is interrupted air supply, eg: bellows type dry blower is interrupted.

Before you spend more money it would be worth your while experimenting with making your air supply "flutter." ie: Difficult to explain, but here goes.

Cut a round metal disc to the inside diameter of the blower delivery, curve the ends so the blown air will make it spin on a shaft.

Drill holes through the pipe slide a rod through then tack weld it to the disc.

When the blower delivers air it will flutter with the spinning disc and help move your fines down the riffle box.

Maybe someone here can draw a diagram to explain it clearly.

hey mate the air is distributed around the box by the counterbalance wjat yoir explaining kind of sounds like the same thing....might have to draw a picture

G0lddigg@ said:hey mate the air is distributed around the box by the counterbalance wjat yoir explaining kind of sounds like the same thing....might have to draw a picture

No, your set up the air is distributed by a constant fan, meaning constant airflow, you need a pulsed airflow so it "puffs" through your riffle box screen. Your counter balance just shakes the whole machine, in a nutshell, useless.

Nightjar said:G0lddigg@ said:hey mate the air is distributed around the box by the counterbalance what your explaining kind of sounds like the same thing....might have to draw a picture

No, your set up the air is distributed by a constant fan, meaning constant airflow, you need a pulsed airflow so it "puffs" through your riffle box screen. Your counter balance just shakes the whole machine, in a nutshell, useless.

you need to put your hand in the box to understand mate, the fan blades i made throw air around in a pulsating motion, one side is heavier with the weight which throws air to that side of the box when it kicks, its the same as every commercial unit available around the world I'd hardly say its useless.

There's two types of blower, bellows and counterbalance and blower the counterbalance and blower versions (mine)

uses the pulse from counterbalance and fan to imitate the water motion and move material down the box while the air blows light material away.

the bellows type used pulse air to lift material up and over the riffles and cannot process as much material around 1/4 from my research. Combining the two doesn't make sense to me, the leaf blower is not designed to build pressure in the same way a bellows can and relies on the counterbalance they are two very different beasts and I don't intent on going down the bellows path as stated above.

apparently this is what they use over the us for the cheap blower.... found on at mitre 10 $400

http://shop.mitre10.com.au/echo-power-blower-25-4cc-pb255es.html

http://shop.mitre10.com.au/echo-power-blower-25-4cc-pb255es.html

- Joined

- Mar 23, 2013

- Messages

- 806

- Reaction score

- 271

Nightjar said:G0lddigg@ said:hey mate the air is distributed around the box by the counterbalance wjat yoir explaining kind of sounds like the same thing....might have to draw a picture

No, your set up the air is distributed by a constant fan, meaning constant airflow, you need a pulsed airflow so it "puffs" through your riffle box screen. Your counter balance just shakes the whole machine, in a nutshell, useless.

Don't know wher you get this idea.

Mine is the same as the one goldigga has built and works great.

DD

- Joined

- Mar 23, 2013

- Messages

- 806

- Reaction score

- 271

G0lddigg@ said:apparently this is what they use over the us for the cheap blower.... found on at mitre 10 $400

http://cp.inkrefuge.com/images\posts/resize to 500(1)_large.jpg

http://shop.mitre10.com.au/echo-power-blower-25-4cc-pb255es.html

I use the honda 4 stroke on mine, but have seen a mate using on of these from bunnings. Cheap and works well enough.

http://www.bunnings.com.au/ryobi-26cc-2-stroke-petrol-blower-vac_p3380402

DD

that looks the good mate, from what i can tell the range is 25cc + with at least 300km air flow that ryobi ticks both boxesDiggerdude said:G0lddigg@ said:apparently this is what they use over the us for the cheap blower.... found on at mitre 10 $400

http://cp.inkrefuge.com/images\posts/resize to 500(1)_large.jpg

http://shop.mitre10.com.au/echo-power-blower-25-4cc-pb255es.html

I use the honda 4 stroke on mine, but have seen a mate using on of these from bunnings. Cheap and works well enough.

http://www.bunnings.com.au/ryobi-26cc-2-stroke-petrol-blower-vac_p3380402

DD

thanks DD

quick update.... finally got the old girl working  tested the box out without the restrictive pipe and got heaps better pressure so I pinched some slotted drain pipe covered it with duct tape and tested her out. There's still some tweaking to do but it held all the lead shot and ironstone i threw in so that got to be a win. I can see that a more powerful blower would really help but i'm pretty chuffed with how its working. Probably the biggest issue was the solid plastic pipe which took up a lot of the wobble from the counterbalance.

tested the box out without the restrictive pipe and got heaps better pressure so I pinched some slotted drain pipe covered it with duct tape and tested her out. There's still some tweaking to do but it held all the lead shot and ironstone i threw in so that got to be a win. I can see that a more powerful blower would really help but i'm pretty chuffed with how its working. Probably the biggest issue was the solid plastic pipe which took up a lot of the wobble from the counterbalance.

** Video to come its taking for ever to convert in youtube *** look forward to constructive feedback

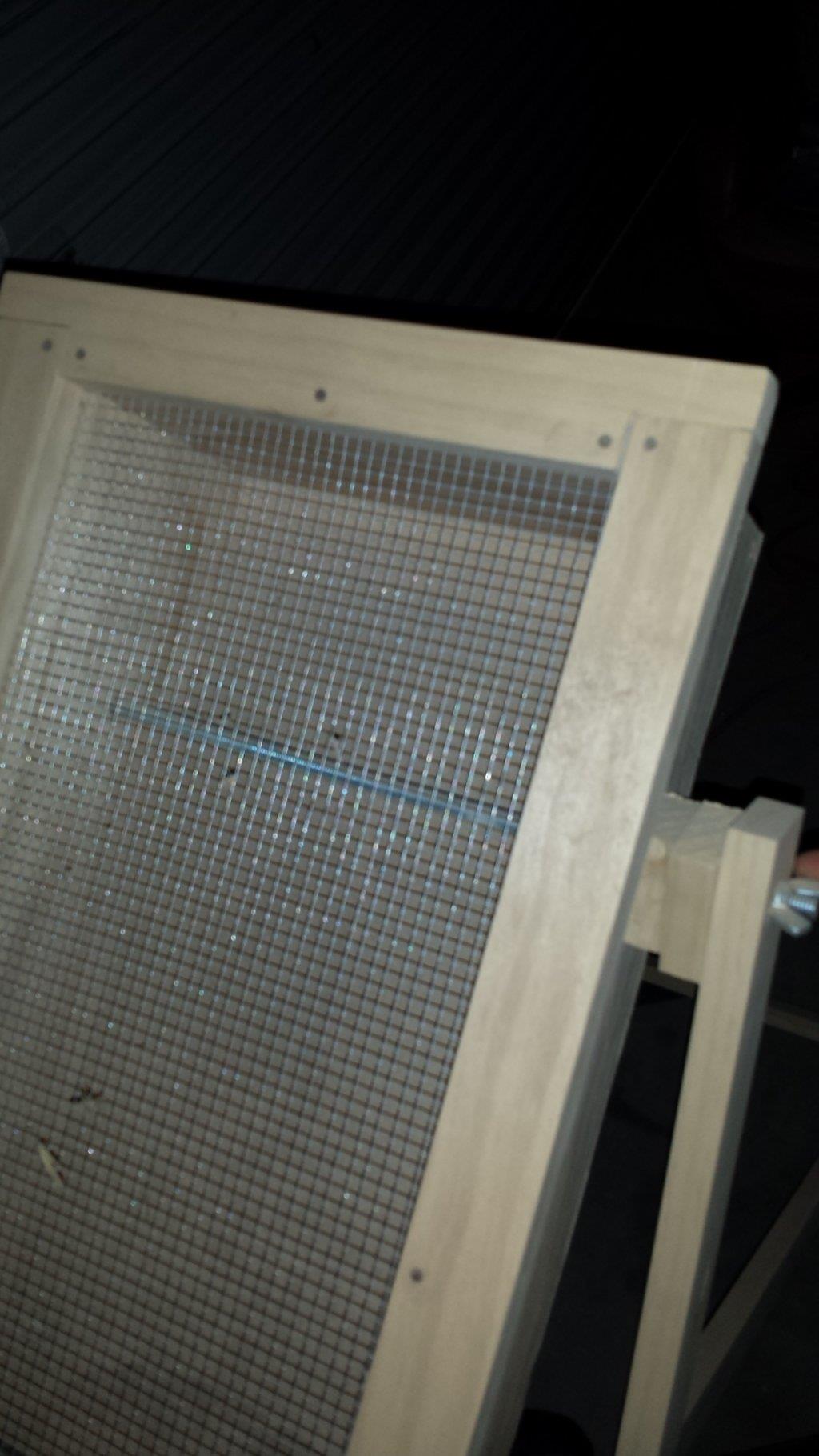

I added some side rails to keep the material from spilling over the edge and a clamp to hold the riffles down.

once it done that there was very little clearance so I had to widen the legs right up.

I mixed a some ironstone and leadshot into some dusty material to test

here you can see when i lifted the riffles they were overloaded with the heavies

final pan out happy with that

looking through all the material that rolled off i couldn't find any ironstone.

tomorrow i'll weld this Tyre nut to a nut for the counterbalance and see if i can get a more aggressive wobble then I'll take it out to creswick for a dry run weather permitting.

** Video to come its taking for ever to convert in youtube *** look forward to constructive feedback

I added some side rails to keep the material from spilling over the edge and a clamp to hold the riffles down.

once it done that there was very little clearance so I had to widen the legs right up.

I mixed a some ironstone and leadshot into some dusty material to test

here you can see when i lifted the riffles they were overloaded with the heavies

final pan out happy with that

looking through all the material that rolled off i couldn't find any ironstone.

tomorrow i'll weld this Tyre nut to a nut for the counterbalance and see if i can get a more aggressive wobble then I'll take it out to creswick for a dry run weather permitting.

here it is in the flesh it took me while to realize that the faster you feed it it the better the material moves through the box.

[video=480,360]http://www.youtube.com/watch?v=xmEgQro8qzg[/video]

[video=480,360]http://www.youtube.com/watch?v=xmEgQro8qzg[/video]

- Joined

- Aug 6, 2013

- Messages

- 323

- Reaction score

- 102

good stuff mate that's great.... no more looking for water now

regards

regards

Similar threads

- Replies

- 13

- Views

- 2K