- Joined

- Aug 6, 2013

- Messages

- 323

- Reaction score

- 102

sounds good mate

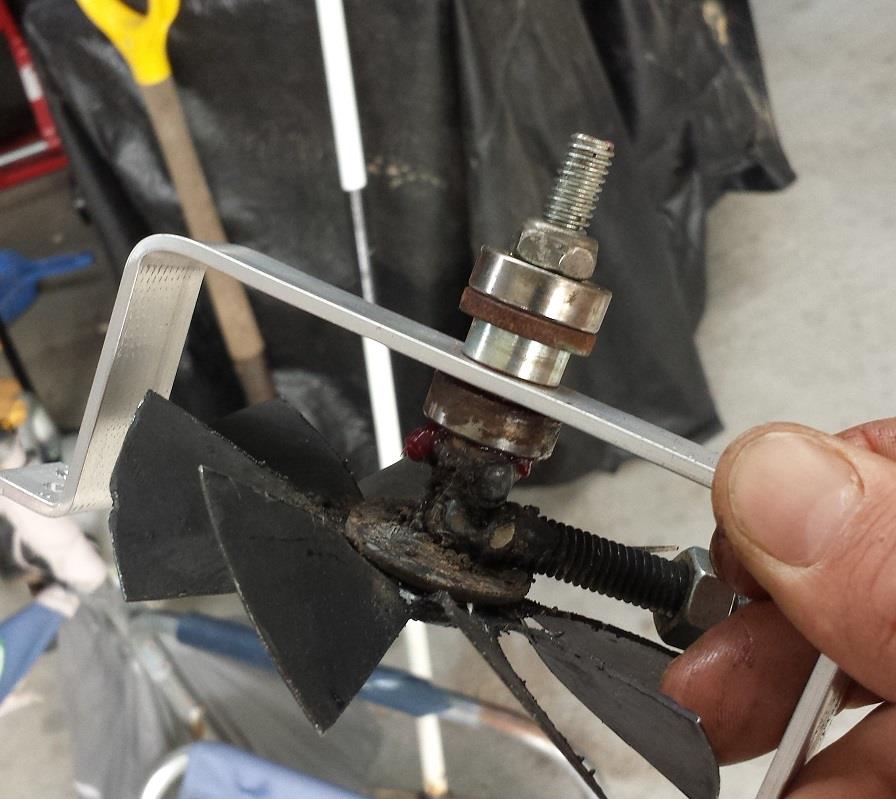

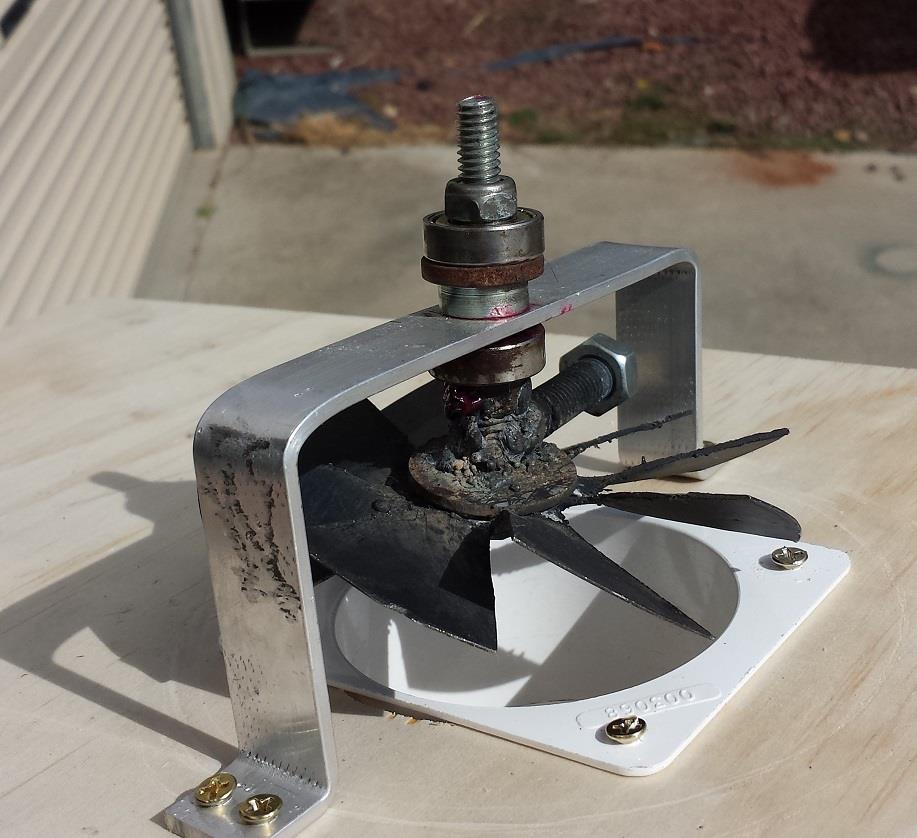

I reckon your counter balance set up will work a treat, it looks just like the keene ones, it should get things wobbling nicely and if it don't you should be able to add another nut for weight.

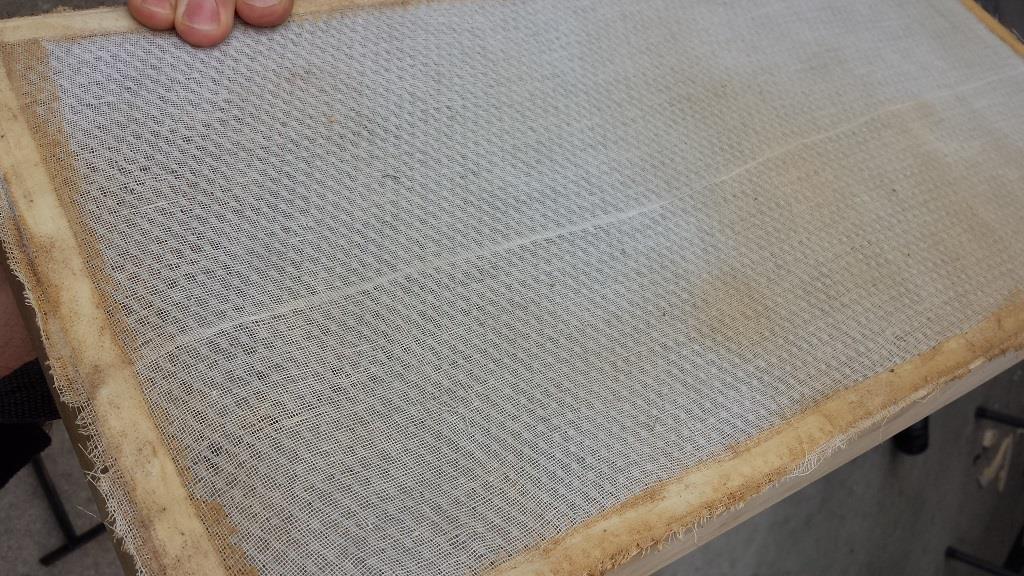

when I said about losing your static, I meant I don't think the static will travel through the wood to your mesh, I realise it won't dissipate but it will stay in the hose unless it can travel through something to the mesh as static won't travel through wood, saying you would lose it was a bad choice of words.

still I reckon your got a great looking unit there and apart from the dust and back breaking digging, you should have a ball using it

thanks for sharing your project

regards tm

I reckon your counter balance set up will work a treat, it looks just like the keene ones, it should get things wobbling nicely and if it don't you should be able to add another nut for weight.

when I said about losing your static, I meant I don't think the static will travel through the wood to your mesh, I realise it won't dissipate but it will stay in the hose unless it can travel through something to the mesh as static won't travel through wood, saying you would lose it was a bad choice of words.

still I reckon your got a great looking unit there and apart from the dust and back breaking digging, you should have a ball using it

thanks for sharing your project

regards tm