Chuky thanks for reply ................. interesting indeed will try mine and see what the go is?

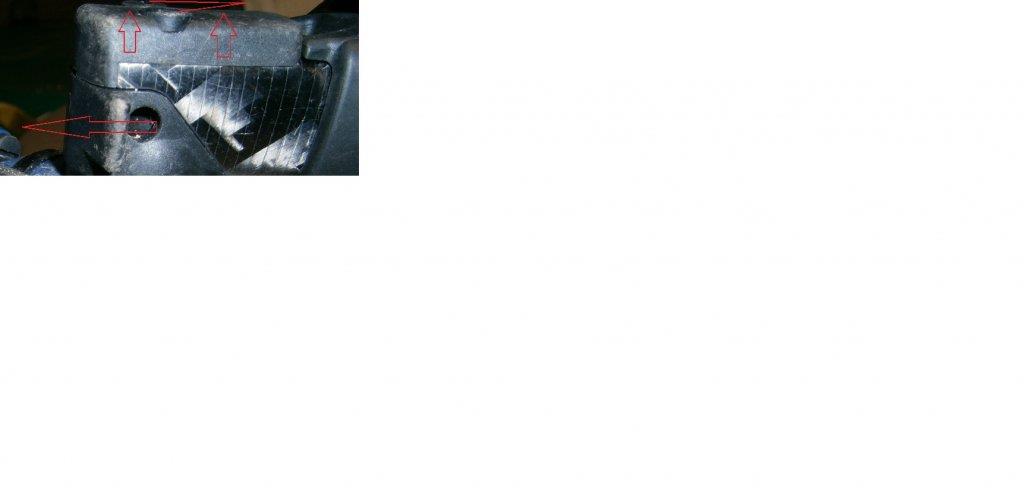

From what I can gather with the shaft not being sealed when used at the beach sand ingress being abrasive powders up the carbon fibre and the powder being so dry is not allowing the spiral cord to glide up and down the shaft internally. I also don't fold completely up and never have just shorten shaft length.

I haven't found to many SDC owners who actually completely fold the machine after use?

Off to check any sound variation

Cheers

Okay an edit is no noise when extending or retracting shaft .............. thankfully, although in saying that have found minelab to be excellent in regards to any problems. But I have found you get a much better response going straight to the source rather than the dealer as in my experiences there are a few that once they have the bucks they don't have a care or concern about any issues afterwards.

Chuky I note your getting this on your new machine also ? Speaker and headphones or just thru headphone jack ?