You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

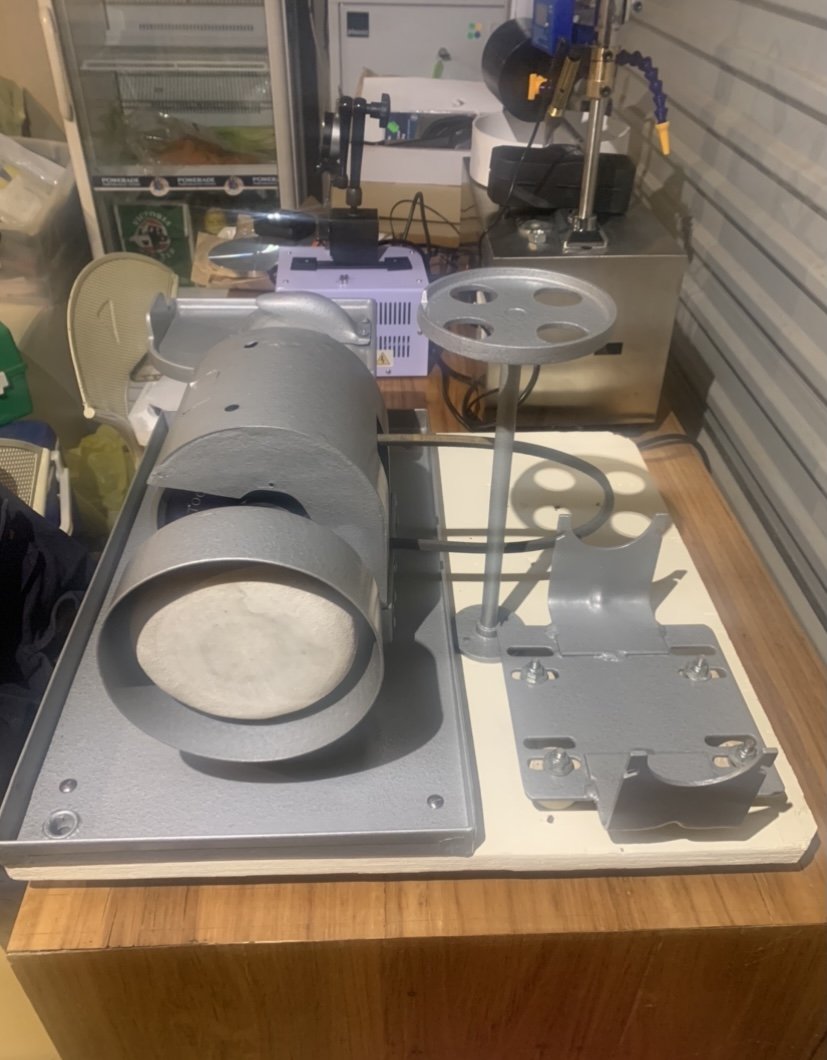

Looking for a pic pre 1970 4in1 Gemmasta

- Thread starter joe

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Stole them from uncle google

Their not the same as your though

Their not the same as your though

Looks great Joe. I know its hindsight but I carefully taped over the original Gemmasta sticker on mine because I knew I couldnt get another one. If youve done all that work in the last two days then youre quicker than me.

Its great to see another machine even older than mine brought back to life. I hope it brings you just as much joy. :Y: :Y:

Its great to see another machine even older than mine brought back to life. I hope it brings you just as much joy. :Y: :Y:

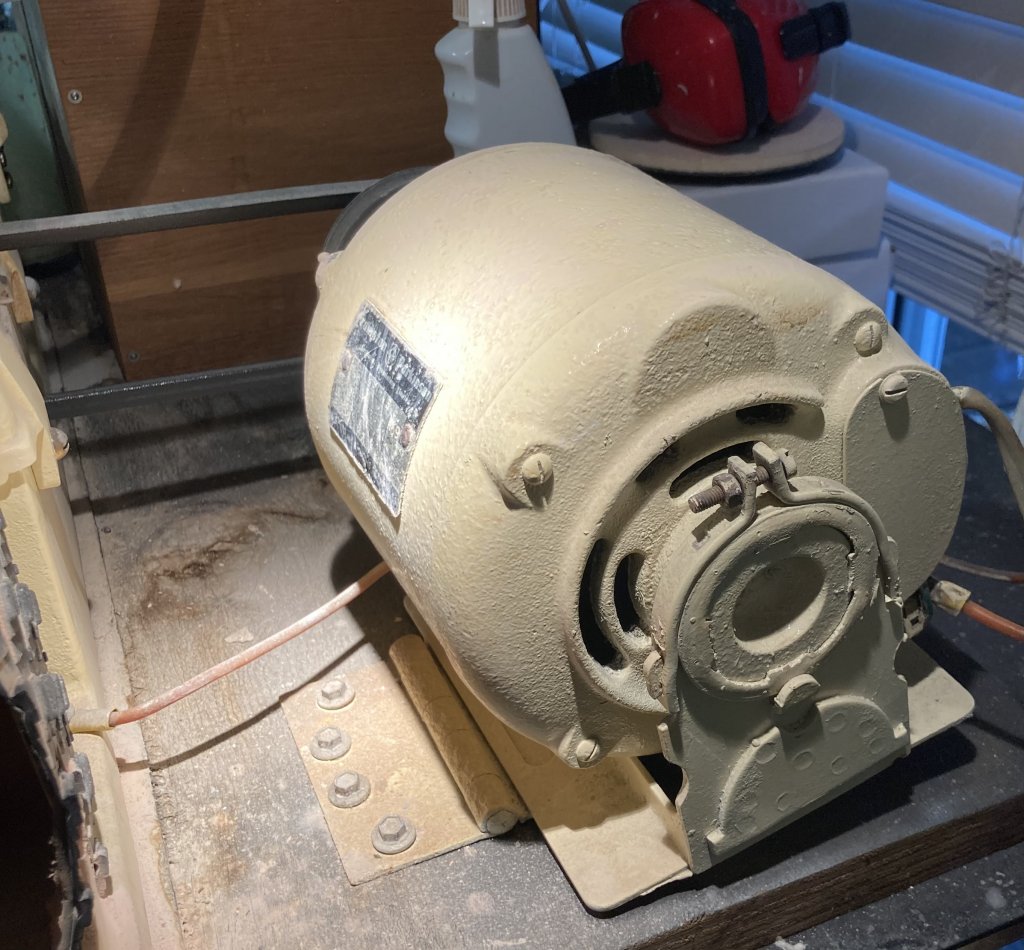

Hey Joe,

I just noticed that youre motor is going to be bolted down on four sides. If you want to change the speed of your machine by shifting the belt onto a different pulley wheel then you will have to loosen the bolts. The person who owned my machine set the motor up on a hinge so that if you are using the slicing wheel you can easily speed it up by just tilting the motor and shifting the belt. Works great.

I just noticed that youre motor is going to be bolted down on four sides. If you want to change the speed of your machine by shifting the belt onto a different pulley wheel then you will have to loosen the bolts. The person who owned my machine set the motor up on a hinge so that if you are using the slicing wheel you can easily speed it up by just tilting the motor and shifting the belt. Works great.

- Joined

- Oct 3, 2019

- Messages

- 1,120

- Reaction score

- 1,000

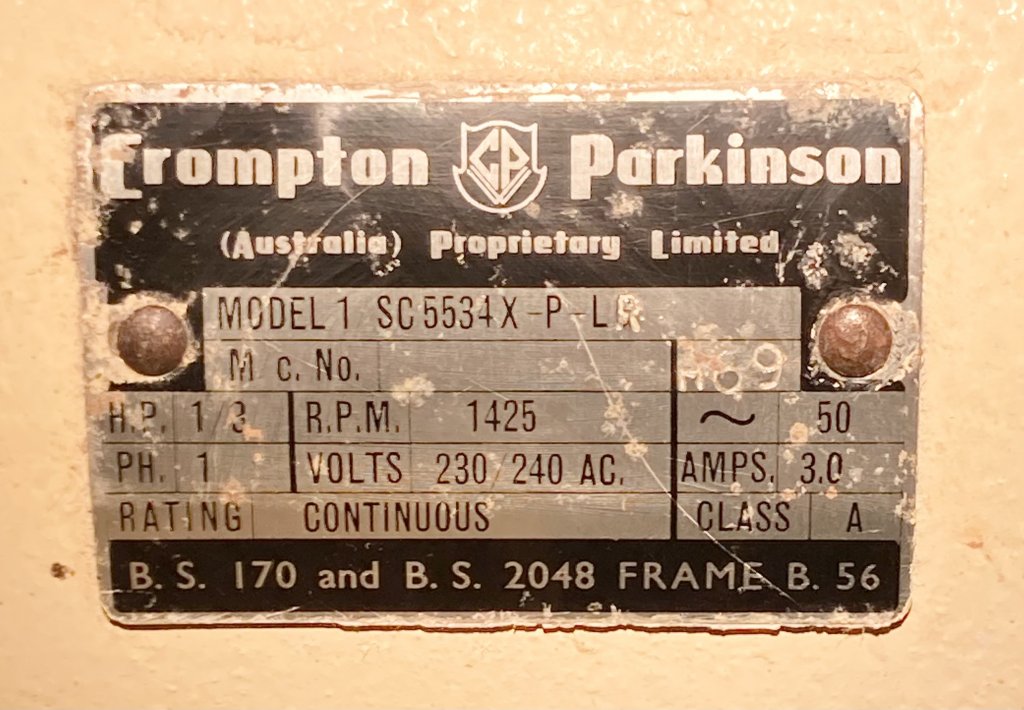

You should check the speed rating on your grinding wheels . Do not exceed that or they could shatter .

The speed can be calculated by knowing the size of the pulleys . If the motor pulley is 4 inch and the shaft pulley is 2 inch then that is a ratio of 2 to 1 . So it is going to now spin at 2 X 1425 = 2850 R.P.M. Just be careful about increasing the speed .

Make sure the frame is earthed , clean the paint off and make a good clean metal to metal contact . Water and electricity do not mix . Has the power point or your house got an R.C.D. fitted ?

The speed can be calculated by knowing the size of the pulleys . If the motor pulley is 4 inch and the shaft pulley is 2 inch then that is a ratio of 2 to 1 . So it is going to now spin at 2 X 1425 = 2850 R.P.M. Just be careful about increasing the speed .

Make sure the frame is earthed , clean the paint off and make a good clean metal to metal contact . Water and electricity do not mix . Has the power point or your house got an R.C.D. fitted ?

Thanks Mike. I had to run off and check my pulley ratios to make sure nothing was going to self destruct.

For cutting and polishing I use a 1:1 ratio, so about 1425 rpm.

For slicing I sometimes like to drop to a smaller pulley on the machine which brings it to 1:1.25 or about 1780 rpm.

Ideally Id like to be able to drop the speed lower than 1425 rpm for polishing but I get the job done.

For cutting and polishing I use a 1:1 ratio, so about 1425 rpm.

For slicing I sometimes like to drop to a smaller pulley on the machine which brings it to 1:1.25 or about 1780 rpm.

Ideally Id like to be able to drop the speed lower than 1425 rpm for polishing but I get the job done.

- Joined

- May 26, 2018

- Messages

- 385

- Reaction score

- 1,145

Martyz said:Thanks Mike. I had to run off and check my pulley ratios to make sure nothing was going to self destruct.

For cutting and polishing I use a 1:1 ratio, so about 1425 rpm.

For slicing I sometimes like to drop to a smaller pulley on the machine which brings it to 1:1.25 or about 1780 rpm.

Ideally Id like to be able to drop the speed lower than 1425 rpm for polishing but I get the job done.

.................................................................................

Maybe one of these, i put one similar on my wood lathe.

https://www.jaycar.com.au/240v-10a-deluxe-motor-speed-controller-kit/p/KC5478

Similar threads

- Replies

- 0

- Views

- 645

- Replies

- 7

- Views

- 795