Ok Mate, I'll give you a call in the morning. Cheers mateSimmo said:Yeah Bogger has the tips right down pat, no doubt.

Rick, ya lunatic, I'm about 200 mtrs from you as the crow flies! Come down and we'll chuck the meter on it!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solar Panels - Information and Questions

- Thread starter HeadsUp

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,271

Redarc are a good unit, I have the bc/dc 25A unit and it's marvellous, but that projecta one is certainly a good bit of kit too, I'll probably fit one in my caravan as I can't see the extra benefit in the redarc, they have similar specs and reliability of both are very good.

That projecta does indeed have genuine MPPT, just watch you don't fit a 24V panel to it as the VOC will only take a 12V panel, bloody redarc is the same, not happy about that!!!

So before you get a solar panel make sure it's a 12v rated one with a VOC of 23v or less.

So yeah ditch the regulator that came with the panel and feed the dc direct into the projecta solar input.

That projecta does indeed have genuine MPPT, just watch you don't fit a 24V panel to it as the VOC will only take a 12V panel, bloody redarc is the same, not happy about that!!!

So before you get a solar panel make sure it's a 12v rated one with a VOC of 23v or less.

So yeah ditch the regulator that came with the panel and feed the dc direct into the projecta solar input.

Thank you guys, I will check in with Simmo and make some decisions. I did read some of Condors stuff but my head was swimming. He does know his stuff and i'm sure if I was able to get my head around his expertise I'd be happy with the result. I am a little bit locked in to what I have now and should be able to make it work reasonably well. Fingers crossed  Regards Rick

Regards Rick

Thanks OP that makes me feel a bit better about what I've got so far.

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,271

I don't think redarc are much better really, just advertising.

condor22

Mike

The simple explanation is Don't regulate twice, yes it will still work, but you won't get full output from the panel. So disconnect one or the other....

Thanks Condor I was hoping you were around  . This is why I like this Forum. You ask advice and you get replies. Really appreciated :Y:

. This is why I like this Forum. You ask advice and you get replies. Really appreciated :Y:

condor22

Mike

No prob - I'll try to keep it simple, but here's why.....

Solar panels generally output an unregulated voltage of about 19-20 volts max.

Once that output has passed through a regulator it drops to 13.8 volts (generally) on a simple cheap regulated panel. (if it's a good quality multi stage the voltage will vary up to 14.5 volts if set for an AGM) You will also get a small drop in output current (AMPS) due to the regulation process and efficiency loss.

So if you then feed that regulated 13.8 volts through another regulator, the voltage may not change as it is again regulated, but you will suffer a further reduction of output Amps.

Most cheaper panels are fitted with basic PWM regulators. The better MPPT regulators i.e. Redarc, Victron etc are far better as they maximise the panels output.

So if you have a good regulator, bypass the one on the panel by disconnecting the wires to the input side of the panels regulator and connect directly to the input of your remote regulator. (extension required)

There is another advantage of doing this. The regulator usually fixed to the rear of the panel is very close to the panels output and the longer cable goes from the output to the battery, which may suffer voltage drop on regulator output depending on length and wire gauge.

By making the longer wiring go from the panel and putting the remote regulator next to the battery, any voltage drop occurs at the regulators input and that voltage is as mentioned near 19-20 volts. So if it drops 1 or 2 volts, so what, the output at the other end being short won't and the battery gets max charge volts.

Solar panels generally output an unregulated voltage of about 19-20 volts max.

Once that output has passed through a regulator it drops to 13.8 volts (generally) on a simple cheap regulated panel. (if it's a good quality multi stage the voltage will vary up to 14.5 volts if set for an AGM) You will also get a small drop in output current (AMPS) due to the regulation process and efficiency loss.

So if you then feed that regulated 13.8 volts through another regulator, the voltage may not change as it is again regulated, but you will suffer a further reduction of output Amps.

Most cheaper panels are fitted with basic PWM regulators. The better MPPT regulators i.e. Redarc, Victron etc are far better as they maximise the panels output.

So if you have a good regulator, bypass the one on the panel by disconnecting the wires to the input side of the panels regulator and connect directly to the input of your remote regulator. (extension required)

There is another advantage of doing this. The regulator usually fixed to the rear of the panel is very close to the panels output and the longer cable goes from the output to the battery, which may suffer voltage drop on regulator output depending on length and wire gauge.

By making the longer wiring go from the panel and putting the remote regulator next to the battery, any voltage drop occurs at the regulators input and that voltage is as mentioned near 19-20 volts. So if it drops 1 or 2 volts, so what, the output at the other end being short won't and the battery gets max charge volts.

Going on your explanation I think I may have jagged it. I will know more when I see Simmo and check a few things out but I'm confident. Thanks Condor

Another issue that Condor eluded to was that at times there are regulators on the back of the panel. I dont know how many that I have had to replace, or simply bypass, ('coz they are glued on with a substance not from this planet!)

These cheap regulators simply cant handle, the current for one, and simply the heat from being in the sun!

So the regulator should be closer to the battery...

These cheap regulators simply cant handle, the current for one, and simply the heat from being in the sun!

So the regulator should be closer to the battery...

condor22

Mike

Simmo,

Any charger wether DC-DC, 240VAC or solar controller, should be as close to the battery as possible to minimise voltage/current loss, using the correct gauge cable to handle the volts/amps.

Similarly, if you connect an inverter, it should also be as close to the battery as possible.

On my previous vehicle, I did voltage test (under load of a 3 way fridge) at the vehicle battery, the Anderson connector on the rear bumper, the connection to the distribution point in the van battery compartment and at the fridge terminals.

With engine running, I started at 13.8V at the car and ended with just under 12V at the fridge. (the drop under no load was much less, but is meaningless because it's what is operating that counts)

Any charger wether DC-DC, 240VAC or solar controller, should be as close to the battery as possible to minimise voltage/current loss, using the correct gauge cable to handle the volts/amps.

Similarly, if you connect an inverter, it should also be as close to the battery as possible.

On my previous vehicle, I did voltage test (under load of a 3 way fridge) at the vehicle battery, the Anderson connector on the rear bumper, the connection to the distribution point in the van battery compartment and at the fridge terminals.

With engine running, I started at 13.8V at the car and ended with just under 12V at the fridge. (the drop under no load was much less, but is meaningless because it's what is operating that counts)

Yes mate, you are 110% correct.

I had a call from a 'mate' one day, he had installed an inverter in the back of his ute. Now give him some credit, he did ring me and ask what cable he needed to feed the inverter.... he baulked at the price of $18(!) a mtr, but I said, well just listen or FO.

After it was all set up, he says can you come 'round and check it all....

Well, well....well....

The end user of this little episode was a microwave oven in the back of his ute!!!

My DC clamp meter at the battery quickly showed him why he had to pay out for good cable, and why he should start his car when warming his lunch....

I had a call from a 'mate' one day, he had installed an inverter in the back of his ute. Now give him some credit, he did ring me and ask what cable he needed to feed the inverter.... he baulked at the price of $18(!) a mtr, but I said, well just listen or FO.

After it was all set up, he says can you come 'round and check it all....

Well, well....well....

The end user of this little episode was a microwave oven in the back of his ute!!!

My DC clamp meter at the battery quickly showed him why he had to pay out for good cable, and why he should start his car when warming his lunch....

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,271

condor22 said:Simmo,

Any charger wether DC-DC, 240VAC or solar controller, should be as close to the battery as possible to minimise voltage/current loss, using the correct gauge cable to handle the volts/amps.

Similarly, if you connect an inverter, it should also be as close to the battery as possible.

On my previous vehicle, I did voltage test (under load of a 3 way fridge) at the vehicle battery, the Anderson connector on the rear bumper, the connection to the distribution point in the van battery compartment and at the fridge terminals.

With engine running, I started at 13.8V at the car and ended with just under 12V at the fridge. (the drop under no load was much less, but is meaningless because it's what is operating that counts)

Jeeezus

I use 0 B&S from bonnet to Aux, bit pricey but it works nicely.

condor22 said:Simmo,

Any charger wether DC-DC, 240VAC or solar controller, should be as close to the battery as possible to minimise voltage/current loss, using the correct gauge cable to handle the volts/amps.

Similarly, if you connect an inverter, it should also be as close to the battery as possible.

On my previous vehicle, I did voltage test (under load of a 3 way fridge) at the vehicle battery, the Anderson connector on the rear bumper, the connection to the distribution point in the van battery compartment and at the fridge terminals.

With engine running, I started at 13.8V at the car and ended with just under 12V at the fridge. (the drop under no load was much less, but is meaningless because it's what is operating that counts)

Yes highlights another advantage of running a dual battery in the rear rather than front of vehicle ................ apart from getting the battery away from the heat, as it usually also gets the source closer to the demand / load :Y: :Y:

On another note the Projecta IDC25 on first fitting I had problems with as was throwing a solar over charge issue spasmodically, since then have fitted a new version where Projecta re set the parameters (Projecta supplied free of charge I add here) ................. 9 months in and not an issue. At under $250 good value for a BCDC charger with inbuilt MPPT solar controller :Y:

I just try to get the "heaviest" cabling between solar panel to fridge or whatever you are using to minimise resistance.

Jaros said:I just try to get the "heaviest" cabling between solar panel to fridge or whatever you are using to minimise resistance.

Fair call for light load items, easiest way to minimise resistance is to minimise the distance

condor22

Mike

It was wired for me on my last ride. 6mm sq was used. The highlight here is that if I was running a compressor fridge, Engel in car and Vitrifigo van fridge pulling 3-4 amps, 6 mm was ok. But when I changed vans it was a 3 way pulling 14 amps.

So wire gauge is not only relevant to the distance between battery and load/charge, current also plays a part.

When wiring a 1-2 kVA inverter bear in mind an inverter pulls about 9 amps per 100W @ 12VDC. So for a microwave sized inverter the load is likely around 110-135 amps depending on microwave. Your talking wire the size of that used on a car battery or bigger and for very short distances.

A good example to think about is that a winch will use anywhere between 350 to 500 amps, look at the cable size used and the short distances run ...

So a short run of heavy 12 volt between battery and inverter, you can always use longer 240VAC wiring between the inverter and microwave where it's not as critical.

So wire gauge is not only relevant to the distance between battery and load/charge, current also plays a part.

When wiring a 1-2 kVA inverter bear in mind an inverter pulls about 9 amps per 100W @ 12VDC. So for a microwave sized inverter the load is likely around 110-135 amps depending on microwave. Your talking wire the size of that used on a car battery or bigger and for very short distances.

A good example to think about is that a winch will use anywhere between 350 to 500 amps, look at the cable size used and the short distances run ...

So a short run of heavy 12 volt between battery and inverter, you can always use longer 240VAC wiring between the inverter and microwave where it's not as critical.

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,271

0 B&S is 50mm2 good for 250A, do it once and do it right :Y: :Y:

Hi everyone. solar panels are alien to me so I wanted to ask some members with experience in these things some questions

I have a set of solar panels mounted on my roofrack {one of the current projects on the go} but Ive never had them hooked up to the system.

They came with the rack at the time. I would like to get them going but I dont know if they are worth salvaging or start from scratch.

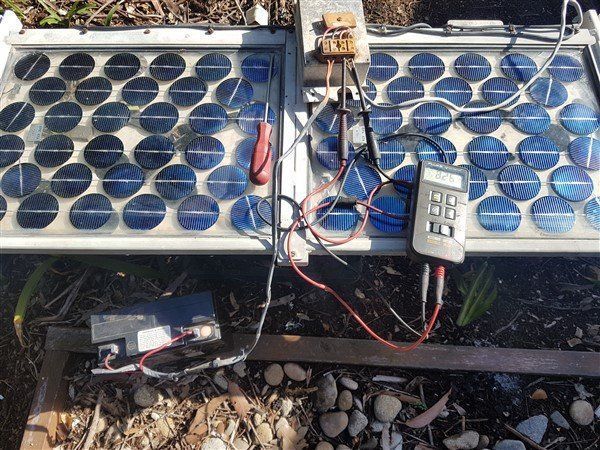

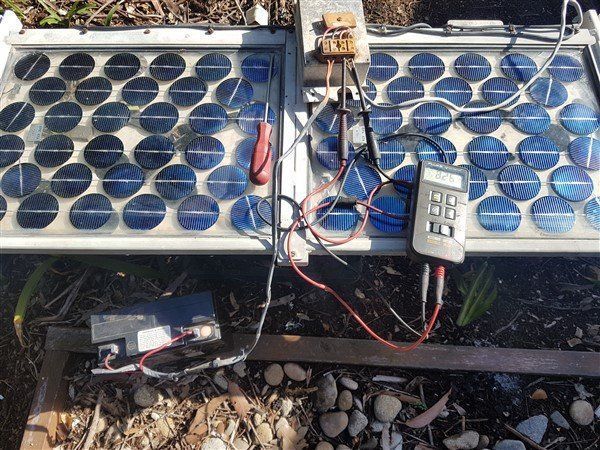

Ive attached some pics to help along the way

Thank you in advance

the panels have BPX47A -7231 and BPX47A -6707 labelled on them.

I sat them in the sun and ran a meter across them. Suprised to see 17v coming out

So I connected a small flat battery [tested at 8.5v] just to see if it needed to flow somewhere. That dropped the panel voltage down to 8.5v so Im assuming it started to read [and hopefully be charging] the small battery.

The control box looks ancient but seems to be working.

Is it worth continuing the exercise or just scrap the whole system for a more current [efficient] type

Cheers

ChrisM

I have a set of solar panels mounted on my roofrack {one of the current projects on the go} but Ive never had them hooked up to the system.

They came with the rack at the time. I would like to get them going but I dont know if they are worth salvaging or start from scratch.

Ive attached some pics to help along the way

Thank you in advance

the panels have BPX47A -7231 and BPX47A -6707 labelled on them.

I sat them in the sun and ran a meter across them. Suprised to see 17v coming out

So I connected a small flat battery [tested at 8.5v] just to see if it needed to flow somewhere. That dropped the panel voltage down to 8.5v so Im assuming it started to read [and hopefully be charging] the small battery.

The control box looks ancient but seems to be working.

Is it worth continuing the exercise or just scrap the whole system for a more current [efficient] type

Cheers

ChrisM

Similar threads

- Replies

- 41

- Views

- 16K

- Replies

- 0

- Views

- 1K

- Replies

- 82

- Views

- 59K