- Joined

- Jan 9, 2019

- Messages

- 825

- Reaction score

- 4,137

I've been pumped for this all week!

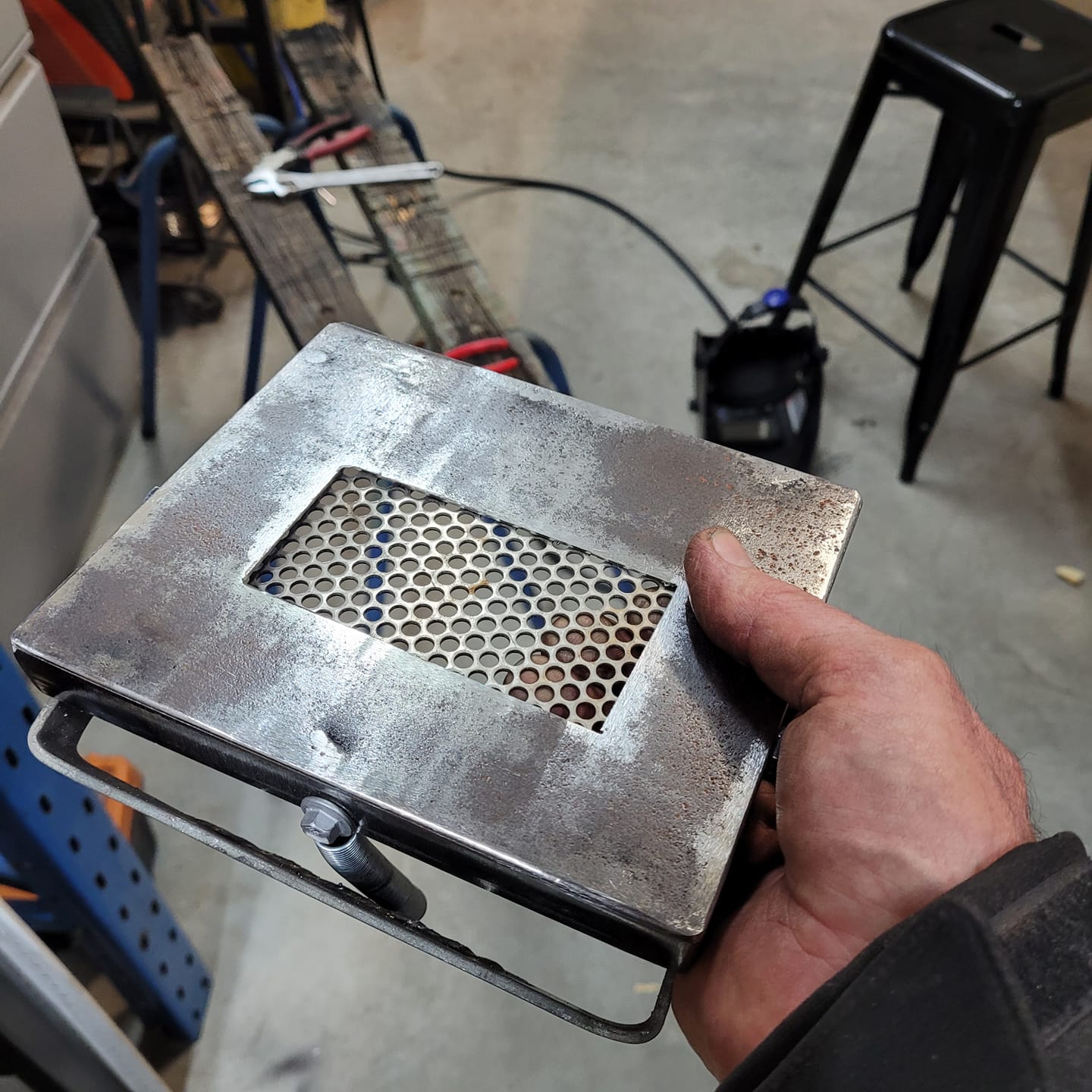

I've been forging blades for a while now, more so recently. Today I practiced the art of forging integral blades, - that is the blade and guard are all one piece. The process of shortening and thickening a round bar of W1 into a usable square block, Isolating the guard prong, then the blade, tang etc is a long and defined one. Every piece of metal, curve and point has to be squeezed out with technique and order. I loved every minute of it.

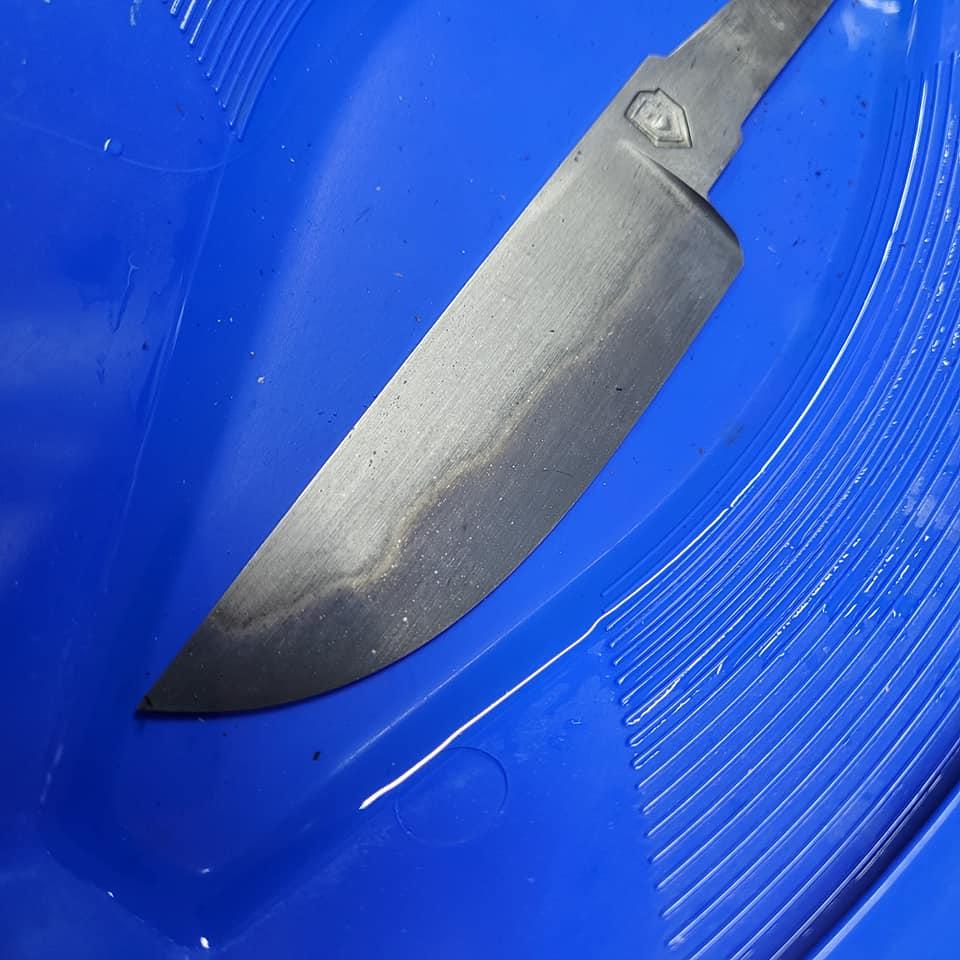

Here's one I did last week. Forged, but the guard is a separate piece. It's already on it's way to a happy new owner.

I've been forging blades for a while now, more so recently. Today I practiced the art of forging integral blades, - that is the blade and guard are all one piece. The process of shortening and thickening a round bar of W1 into a usable square block, Isolating the guard prong, then the blade, tang etc is a long and defined one. Every piece of metal, curve and point has to be squeezed out with technique and order. I loved every minute of it.

Here's one I did last week. Forged, but the guard is a separate piece. It's already on it's way to a happy new owner.