Thanks for the contact info Tom V

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wals' Hi-banker Specifications

- Thread starter WalnLiz

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Sep 13, 2015

- Messages

- 591

- Reaction score

- 700

aussiefarmer said:Thefossickingkid uses both my favorite tools aaarrrhhh arrrhhh aahhhh its hammer time

The old gentle persuader or universal key

I tried my Walbanker out last weekend at Tuena.

I think I might have a few issues that are preventing it from working at its most efficient level.

One is that I had to run it with out the legs attached. So I could only prop it up using what was close at hand and then guessing at the correct angle and level.

Another was the spray bar, do i have the right water preasure running through the pump <hose <spray bar and is the spray bar cut right i.e the amount of slots and are they cut to deap or not cut wide enough and at the right depth etc

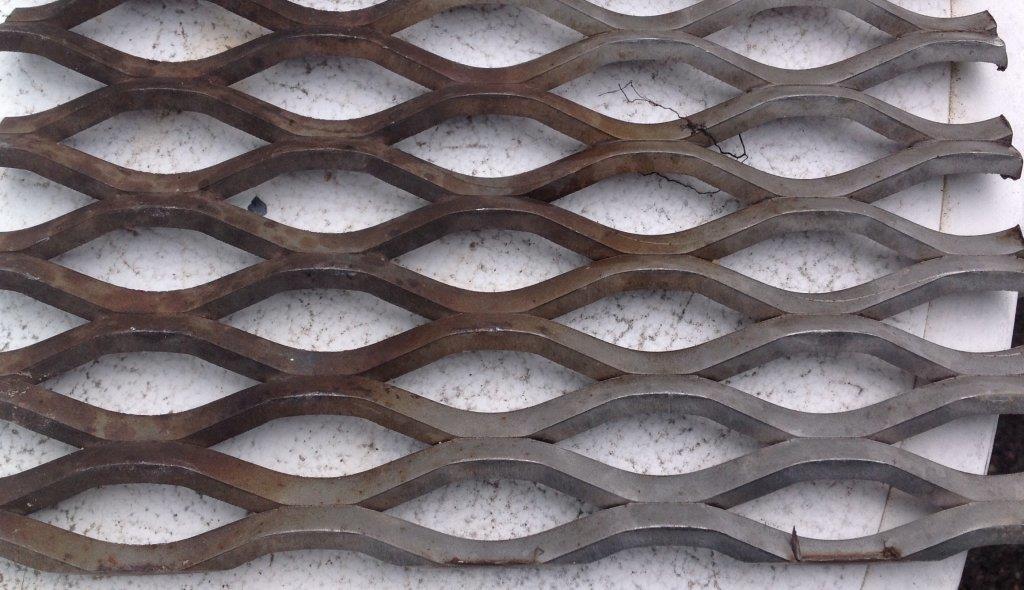

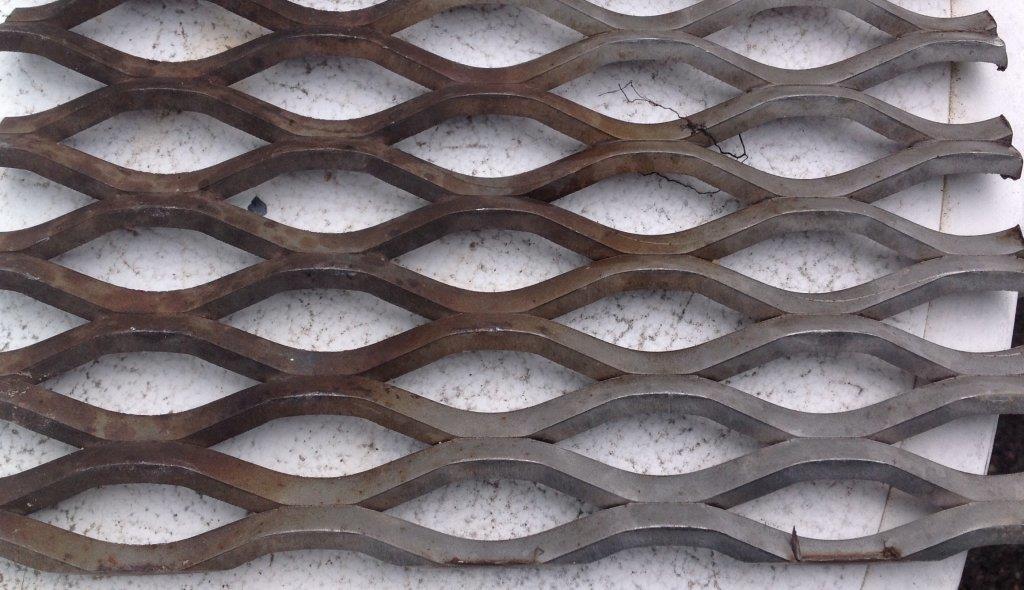

Also I am using the heavier and smaller expanded mesh. 10mm hight with 10mm apertures.

Is there to much/to little water running over the expanded mesh and with the lower profile and smaller openings of the mesh, it seems that I am getting a lot of gravel and stones clogging up the mesha and then consequentially clogging up the L shaped bread crate as well.

I think I might have a few issues that are preventing it from working at its most efficient level.

One is that I had to run it with out the legs attached. So I could only prop it up using what was close at hand and then guessing at the correct angle and level.

Another was the spray bar, do i have the right water preasure running through the pump <hose <spray bar and is the spray bar cut right i.e the amount of slots and are they cut to deap or not cut wide enough and at the right depth etc

Also I am using the heavier and smaller expanded mesh. 10mm hight with 10mm apertures.

Is there to much/to little water running over the expanded mesh and with the lower profile and smaller openings of the mesh, it seems that I am getting a lot of gravel and stones clogging up the mesha and then consequentially clogging up the L shaped bread crate as well.

WalnLiz

Wal nLiz

Way too many slots in the spray bar. For a pump with a capacity of around 200L/min you can only run 13 or max 14 slots. If your mesh is clogging up you haven't got enough water volume going through the box.

On the riser place a 30cm length of 4cm wide masking tape. Measure in from both ends 10cm and mark with a pen. Divide the section between these at 2cm intervals, giving you 14 slots, and cut these slots using a "drop saw" from one side of the masking tape to the other. This will give you the right sized slots.

The crate can not be more than 1/4 full at any time, and is running at optimum when there is a small amount of carpet exposed. If it's blocked you need to adjust slope and water volume to suit. If you're new to "Banking" this exercise can take you a few trips to get right.

Wal.

On the riser place a 30cm length of 4cm wide masking tape. Measure in from both ends 10cm and mark with a pen. Divide the section between these at 2cm intervals, giving you 14 slots, and cut these slots using a "drop saw" from one side of the masking tape to the other. This will give you the right sized slots.

The crate can not be more than 1/4 full at any time, and is running at optimum when there is a small amount of carpet exposed. If it's blocked you need to adjust slope and water volume to suit. If you're new to "Banking" this exercise can take you a few trips to get right.

Wal.

Thanks Wall

Will buy a new riser and try your suggestions for cutting out the slots.

When i ran the Honda wx15 in Tuena it was running at about half throttle and seemed a good volume of water was being sprayed onto the material and was being broken up. But I was worried I might be pushing to much volume and with using the smaller expanded mesh that was also causing a problem with clogging in the mesh and the bread crate.

I should have taken a video while it was set up and running but did not think to.

Will buy a new riser and try your suggestions for cutting out the slots.

When i ran the Honda wx15 in Tuena it was running at about half throttle and seemed a good volume of water was being sprayed onto the material and was being broken up. But I was worried I might be pushing to much volume and with using the smaller expanded mesh that was also causing a problem with clogging in the mesh and the bread crate.

I should have taken a video while it was set up and running but did not think to.

Colmaca

Colin

This is what you will get when you get it right

TheFossickingKid

Angus Madden

I was starting it for the first time and cause of the compression it slipped out of my hand and broke the little plastic thing in the fuel line that connects it to the fuel tank.

Colmaca said:This is what you will get when you get it right

https://www.prospectingaustralia.com/forum/img/member-images/1543/1442719251_p1020466.jpg

https://www.prospectingaustralia.com/forum/img/member-images/1543/1442719280_p1020468.jpg

Ok mine does not look that clear .. Even the bread crate gets clogged up with small stones and gravel.

Have to look at why and work out a solution. i think I might be washing out gold once the mesh and bread crate become overly filled with material.

Colmaca

Colin

you need to run the water/angle so it don't clog up the gold will stay at the top. as seen I never get much at the bread create

When running I look at the bread crate to ensure that all the little rocks and stuff are dancing around.

Don't lift the cable tray to look as you will cause a surge throwing your judgment out.

The small rocks trapped in behind the upright positions is called a fluid bed and keeping that active is paramount.

With a banker like the WalBanker I chuck in about 4 or 5 shovel fulls then check on what is happening then finally adjust to suit.

Start with the banker about 4" high at the back then adjust your flow and angle to suit what you are processing.

Have to get you up to Oallen and that will test you on flour gold. :lol:

Don't worry, You would have to be doing something overly drastically wrong to lose a lot of Gold.

Tuena has a lot of iron stone and it is a small challenge to keep things running smoothly.

Don't lift the cable tray to look as you will cause a surge throwing your judgment out.

The small rocks trapped in behind the upright positions is called a fluid bed and keeping that active is paramount.

With a banker like the WalBanker I chuck in about 4 or 5 shovel fulls then check on what is happening then finally adjust to suit.

Start with the banker about 4" high at the back then adjust your flow and angle to suit what you are processing.

Have to get you up to Oallen and that will test you on flour gold. :lol:

Don't worry, You would have to be doing something overly drastically wrong to lose a lot of Gold.

Tuena has a lot of iron stone and it is a small challenge to keep things running smoothly.

Hi Nucopia, cut too many slots in my spray bar too; used the soldering iron and some cable tie to weld the slots up. Use the hot shaft , not the end; put the cable tie into the cut, apply the iron, when the pipe melts work the iron back and forth on the width of the cut, gradually work the length of the cut, looks a bit rough ,but doesn't leak.

Thanks limpalot

Already went out and bought a new raiser today.

Will cut it next week.

Still need to orginise getting the holes cut in the cross members to take the legs then I can adjust the angle a lot easier.

Its all a learning curve and im trying to absorb all the info and apply it in a practical manner that works.

Thanks guys really appreciate all the help !

Already went out and bought a new raiser today.

Will cut it next week.

Still need to orginise getting the holes cut in the cross members to take the legs then I can adjust the angle a lot easier.

Its all a learning curve and im trying to absorb all the info and apply it in a practical manner that works.

Thanks guys really appreciate all the help !

- Joined

- Sep 13, 2015

- Messages

- 29

- Reaction score

- 79

@Wal I thought for the Honda WX15 pump I need to cut 20 slots 1 cm apart and 1,5 cm in length into the spray bar (diameter=25mm) to work like yours? Haven't got my parts yet to finish the cad drawings for the community. Want to make sure everything is correct.

Are these dimensions correct?

for Honda WX15 pump (240l/min)

spray bar diameter 25 mm

20 slots (width = 2 mm)

1 cm apart

1,5 cm in length

Are these dimensions correct?

for Honda WX15 pump (240l/min)

spray bar diameter 25 mm

20 slots (width = 2 mm)

1 cm apart

1,5 cm in length

I use these with great success,

The slots are 1.5 mm thick.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=8328&p=1

The slots are 1.5 mm thick.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=8328&p=1

WalnLiz

Wal nLiz

daniel2015 said:@Wal I thought for the Honda WX15 pump I need to cut 20 slots 1 cm apart and 1,5 cm in length into the spray bar (diameter=25mm) to work like yours? Haven't got my parts yet to finish the cad drawings for the community. Want to make sure everything is correct.

Are these dimensions correct?

for Honda WX15 pump (240l/min)

spray bar diameter 25 mm

20 slots (width = 2 mm)

1 cm apart

1,5 cm in length

http://www.schweinert.com/upload/walbanker_ds_spray_bar.jpg

G'day Daniel,

There's many varieties around of Walbanker spray bars, and many work very well. ( but by the same token many I've seen don't work at all)

I run my spray bars as per post 964 above, and will not deviate from those measurements on bankers I personally supply. Tried countless variations over the years and the one I've described has worked best for me by far.

I use only heavy duty UV protected risers 45cm long, 32mm OD, 22mm ID.

I run either 13 or 14 slots which when cut as described in above post measure...slot opening 20mm...slot width 2.5mm, and spacing 2cm apart.

These spray bars are for the WX 15 or any pump that can deliver at least 220L/min. With the WX 15 I run the pump at about 3/4 throttle at a delivery of about 190L/min.

Wal.

- Joined

- Sep 13, 2015

- Messages

- 29

- Reaction score

- 79

@Wal Thanks very much! So the info from your video about the spray bar is rather old then.

- Joined

- Sep 13, 2015

- Messages

- 29

- Reaction score

- 79

LOL want to make everything exact, just did some calculations for the spray bar. Seems like the total surface of the slots should not exceed 650 mm2 or you loose pressure. The thickness of the 32 mm pipe or riser makes the water jet more focused therefore the wall thickness of 5 mm.

13 slots (20mm length and 2,5 mm width) = 650 mm2 (Wal's actual info)

20 slots (15mm length and 2 mm width) = 600 mm2 (Info from Wal's Video)

Honda WX15 connector (1,5" = 38,1mm) = 1140 mm2

13 slots (20mm length and 2,5 mm width) = 650 mm2 (Wal's actual info)

20 slots (15mm length and 2 mm width) = 600 mm2 (Info from Wal's Video)

Honda WX15 connector (1,5" = 38,1mm) = 1140 mm2

Main thing is volume over pressure.

There would be small variations as to who has what to build with.

If you stick with Wal's formula, You would be in Ball Park.

With the spray bars I have, I run the pump a little bit harder to make up for pressure.

IE; you can have a nice set of super spray bars that will cut every thing to peices

but be lacking in volume that is required for the Banker to operate efficiently.

Or heaps of volume but no cutting action.

There would be small variations as to who has what to build with.

If you stick with Wal's formula, You would be in Ball Park.

With the spray bars I have, I run the pump a little bit harder to make up for pressure.

IE; you can have a nice set of super spray bars that will cut every thing to peices

but be lacking in volume that is required for the Banker to operate efficiently.

Or heaps of volume but no cutting action.

Thanks for all the help and advice guys .. Much apreciated.

Tomorrow I intend to cut out the holes for the PVC legs

I know the holes need to be cut offset so that that the top of the back and front legs point inwards at about 20 degrees.

I bought 4 pieces of 1 meter x 32mm pipe. How long do I cut each pipe ?

Tomorrow I intend to cut out the holes for the PVC legs

I know the holes need to be cut offset so that that the top of the back and front legs point inwards at about 20 degrees.

I bought 4 pieces of 1 meter x 32mm pipe. How long do I cut each pipe ?

Similar threads

- Replies

- 15

- Views

- 986

- Replies

- 4

- Views

- 977