*Disclaimer Warning*

( In no way is the Prospecting Australia forum, or myself, reliable or held responsible for any damage if you attempt to copy any of the shown experiments or subject of text and images shown or disgussed in this topic. I do not encourage anyone to try or attempt anything of such subjects, safety precautions are not listed, nor are the chemicals involved. You have been warned. )

With the storm coming over head fast I thought I'd fit in some quick fun for the day and share it!

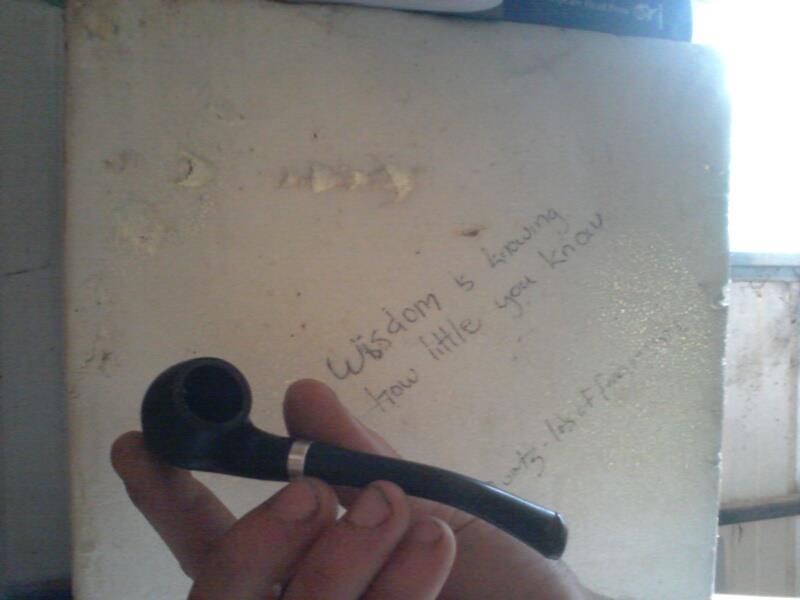

It all began from a shallow hole search for clay in the back garden, took a long time, but eventually after a couple of pokes holes I found a nice ball of a semi clean brown clay which stuck to itself and easily rolled and pressed into shape. I figured I'd give the old clay pioe a go, with a small amount of clay knowledge in the memory bank I set to finger shaping out the bowl, and rolled up a neck on the table. Using a bit if coat hanger wire, I was able to carefully pierce the stem giving it a neat hole. Quickly I roughed uo the sectiins to be joined and with a hok of spit I squished them together the best I could. Generally a potter would make sure the clay was free of dirt, rock and also use a 'slick' glue ..but whis got the time for those details

Pretty happy with the desgn ( after a couple of attempts ) I made a makeshift rocket stove kiln from spare bricks, ( a dug hole would have been better ), burning a good load of fuel to leave a nice glowing bed of heat at its base. Even though I knew the clay was dreadfully wet, and a crack had already formed on its stem by air drying, I carefully placed it upon the embers when *bang crackple pop* the pipe exploded into a million pieces like a liquid nitrogen treated rose! Oh well.. I left it in to see hiw well any if it may survive and to see the results of the clay after firing.

As this was a fail and a nice warm fire / furnace was nice n warming as the clouds crept in, I smashed up some bits of Malachite, carefully sprinkled it onto the embers before re-fueling it with some wood and a few chunks of fresh charcoal crunched up over it to help the malachite -> copper conversion. Being an open furnace I knew very little would produce from it but had a go anyway. Sealing uo the brick oven inlet and chimney as best as I could for the reaction to take place.

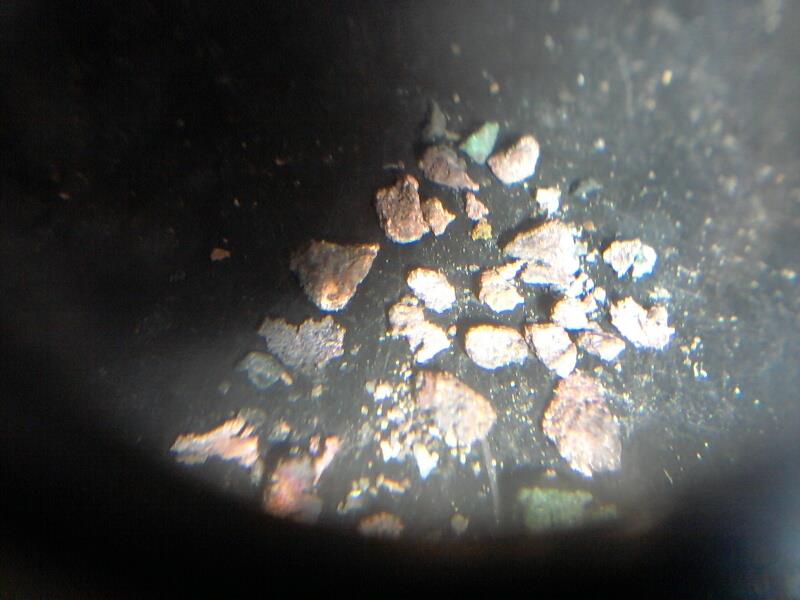

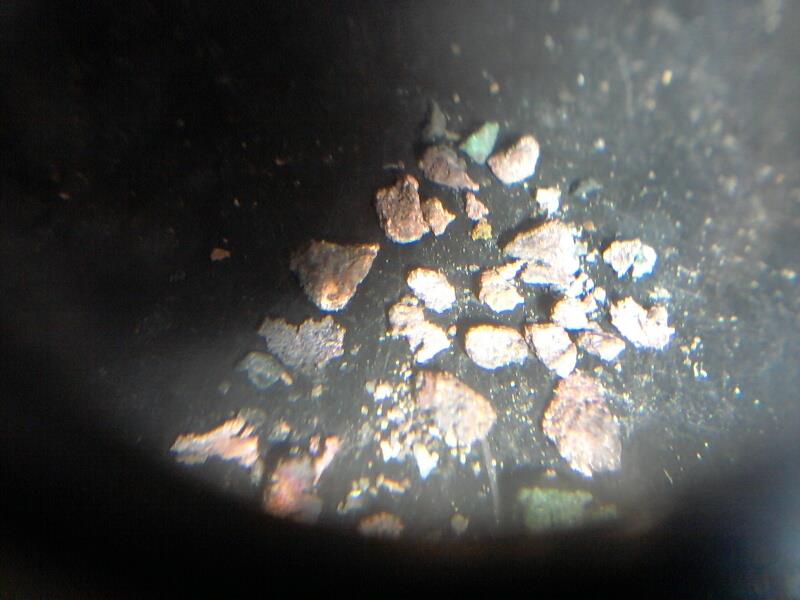

After around an hour ( and not enough heat in the flame ), the doomed rains had started dribbling, eventually putting out the fire. After letting it cool a while, I kicked it all down ( carefully ), and using a scoop; I shovelled the ash remains into a pan to see what we had. Obviously, one hell of a mess! I could easily recover what remains of the pipe were left in the pile, they didn't look real happy at all, but the copper had deposited a lovely coating / sheen to the bits. Then looking into what else I had, I could see some malachite still which didn't crush correctly, and a few copper sparkles and small copper 'nuggets', some with a very famous 'reef' shape, wire like and random. A lot of unreacted malachite or half reacted ore was in the remains too. Rather exciting I say!

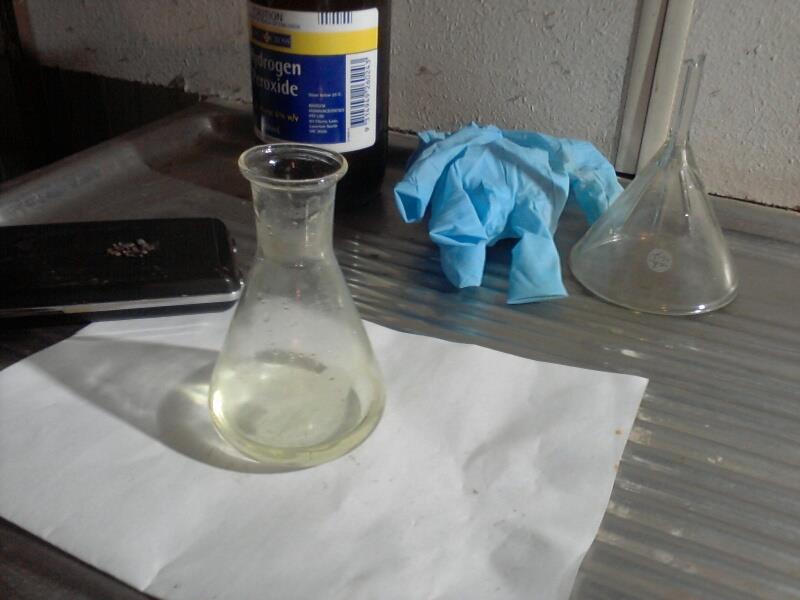

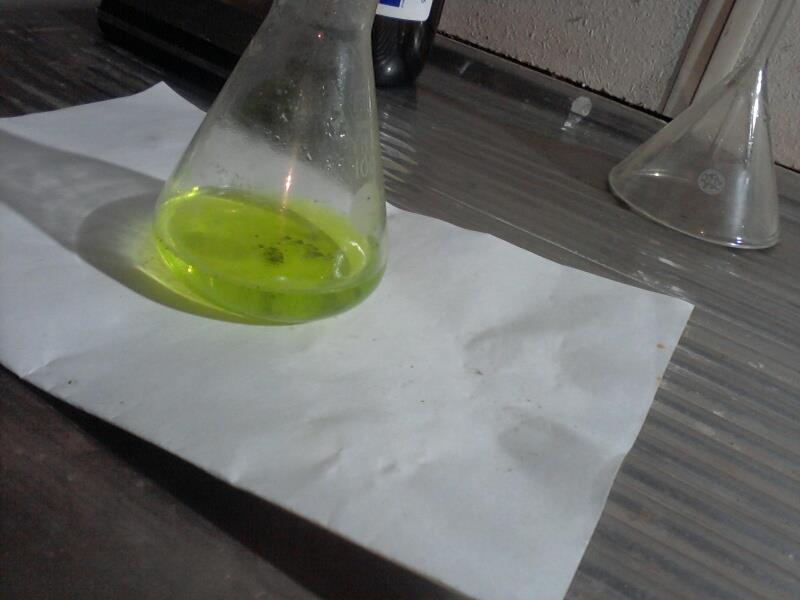

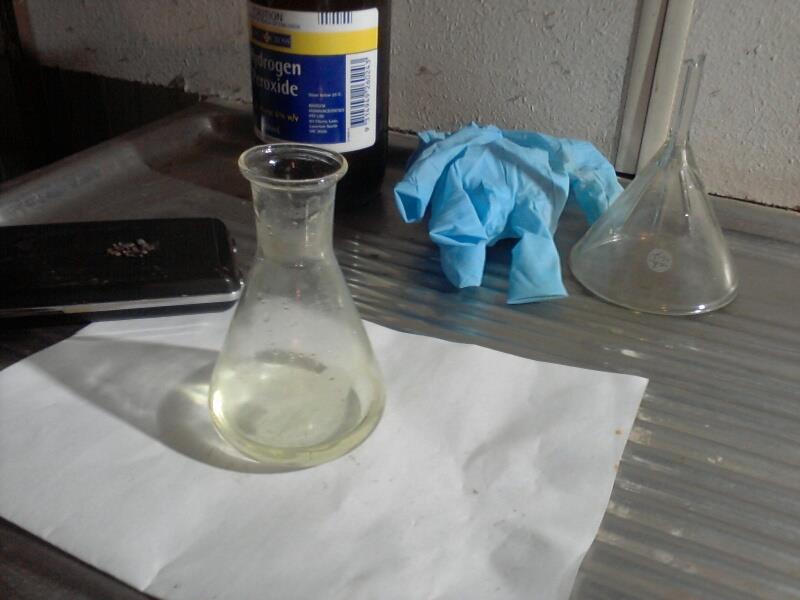

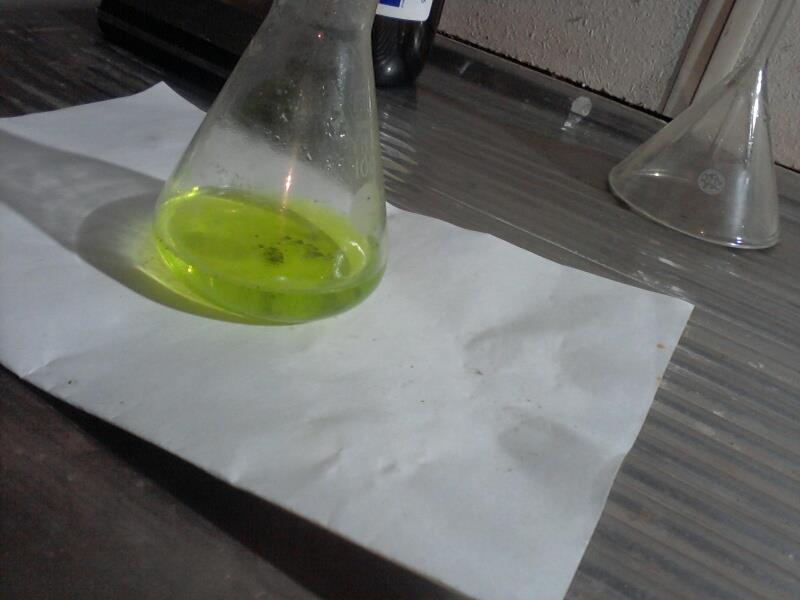

So for the final test to make sure I had made copper ( no doubt by its color anyway ), I dissolved it in some acid, using all safety precaution such as nitrile gloves, bi carb neutralising water nearby for spills etc, which you can cleary see turns a green indication once its done its work. What's left in the bottom is probably bits of clay. Thank you for having a read if another experimental day of mine!

*Disclaimer Warning*

( In no way is the Prospecting Australia forum, or myself, reliable or held responsible for any damage if you attempt to copy any of the shown experiments or subject of text and images shown or disgussed in this topic. I do not encourage anyone to try or attempt anything of such subjects, safety precautions are not listed, nor are the chemicals involved. You have been warned. )

( In no way is the Prospecting Australia forum, or myself, reliable or held responsible for any damage if you attempt to copy any of the shown experiments or subject of text and images shown or disgussed in this topic. I do not encourage anyone to try or attempt anything of such subjects, safety precautions are not listed, nor are the chemicals involved. You have been warned. )

With the storm coming over head fast I thought I'd fit in some quick fun for the day and share it!

It all began from a shallow hole search for clay in the back garden, took a long time, but eventually after a couple of pokes holes I found a nice ball of a semi clean brown clay which stuck to itself and easily rolled and pressed into shape. I figured I'd give the old clay pioe a go, with a small amount of clay knowledge in the memory bank I set to finger shaping out the bowl, and rolled up a neck on the table. Using a bit if coat hanger wire, I was able to carefully pierce the stem giving it a neat hole. Quickly I roughed uo the sectiins to be joined and with a hok of spit I squished them together the best I could. Generally a potter would make sure the clay was free of dirt, rock and also use a 'slick' glue ..but whis got the time for those details

Pretty happy with the desgn ( after a couple of attempts ) I made a makeshift rocket stove kiln from spare bricks, ( a dug hole would have been better ), burning a good load of fuel to leave a nice glowing bed of heat at its base. Even though I knew the clay was dreadfully wet, and a crack had already formed on its stem by air drying, I carefully placed it upon the embers when *bang crackple pop* the pipe exploded into a million pieces like a liquid nitrogen treated rose! Oh well.. I left it in to see hiw well any if it may survive and to see the results of the clay after firing.

As this was a fail and a nice warm fire / furnace was nice n warming as the clouds crept in, I smashed up some bits of Malachite, carefully sprinkled it onto the embers before re-fueling it with some wood and a few chunks of fresh charcoal crunched up over it to help the malachite -> copper conversion. Being an open furnace I knew very little would produce from it but had a go anyway. Sealing uo the brick oven inlet and chimney as best as I could for the reaction to take place.

After around an hour ( and not enough heat in the flame ), the doomed rains had started dribbling, eventually putting out the fire. After letting it cool a while, I kicked it all down ( carefully ), and using a scoop; I shovelled the ash remains into a pan to see what we had. Obviously, one hell of a mess! I could easily recover what remains of the pipe were left in the pile, they didn't look real happy at all, but the copper had deposited a lovely coating / sheen to the bits. Then looking into what else I had, I could see some malachite still which didn't crush correctly, and a few copper sparkles and small copper 'nuggets', some with a very famous 'reef' shape, wire like and random. A lot of unreacted malachite or half reacted ore was in the remains too. Rather exciting I say!

So for the final test to make sure I had made copper ( no doubt by its color anyway ), I dissolved it in some acid, using all safety precaution such as nitrile gloves, bi carb neutralising water nearby for spills etc, which you can cleary see turns a green indication once its done its work. What's left in the bottom is probably bits of clay. Thank you for having a read if another experimental day of mine!

*Disclaimer Warning*

( In no way is the Prospecting Australia forum, or myself, reliable or held responsible for any damage if you attempt to copy any of the shown experiments or subject of text and images shown or disgussed in this topic. I do not encourage anyone to try or attempt anything of such subjects, safety precautions are not listed, nor are the chemicals involved. You have been warned. )