You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My sluice project

- Thread starter Goldslave

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SuperPeter

Peter

- Joined

- Jul 24, 2013

- Messages

- 72

- Reaction score

- 9

Nice build, haven't seen spray bars like them b4  hope to c a video of it in action

hope to c a video of it in action

TenOunce Tone

tony

very nice. i like the spray bars and the classifier mesh. good luck with it

cheers tone

cheers tone

I lke the way you roll Goldslave, the beast looks tough and ready for a couple of hundred kg per hour

Take 2

I am having all sorts of issues with this gadget (Computer) my partner says it's got something to do with my age? bloody women, nothing like a wanna be comedian in the house!!

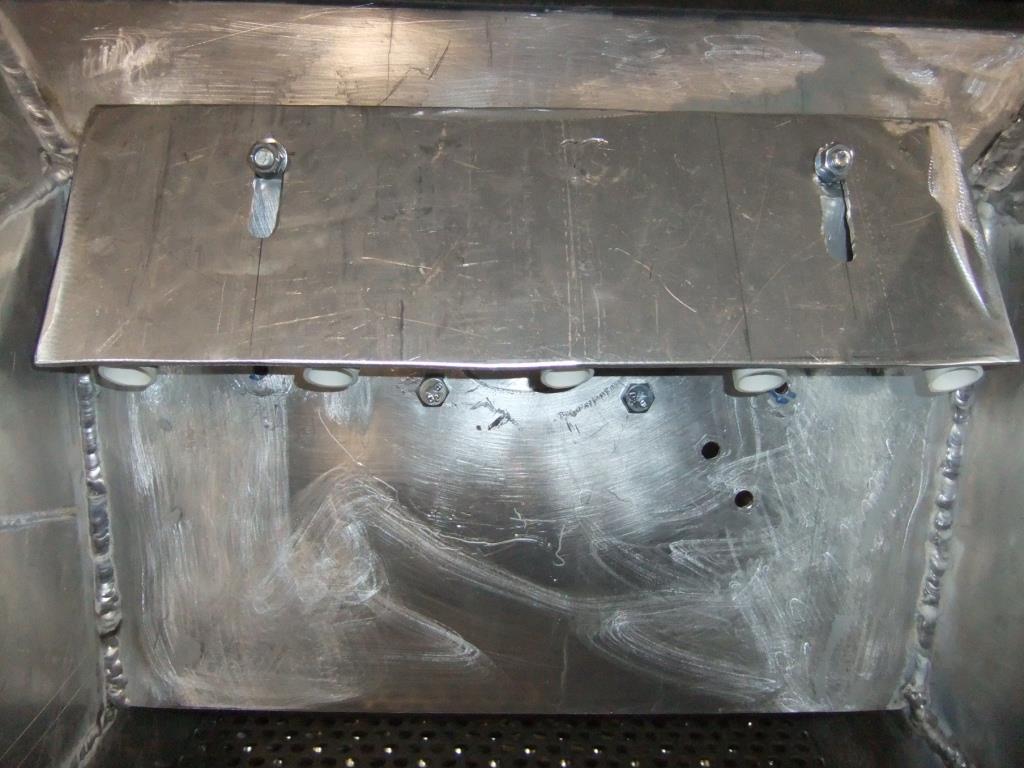

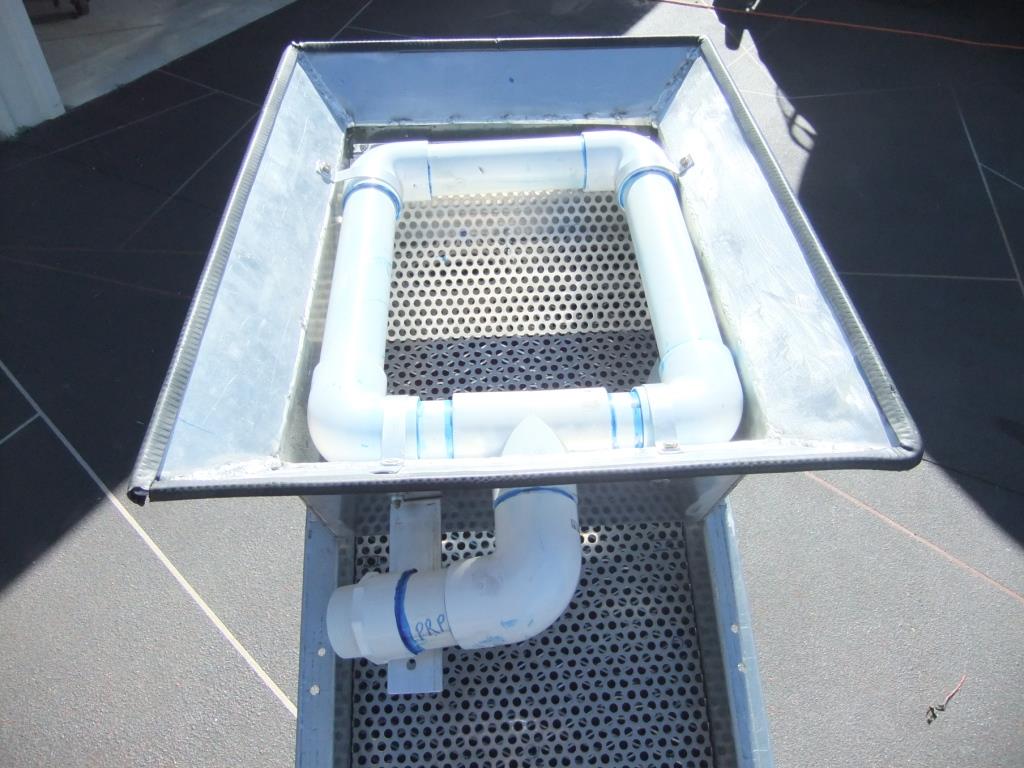

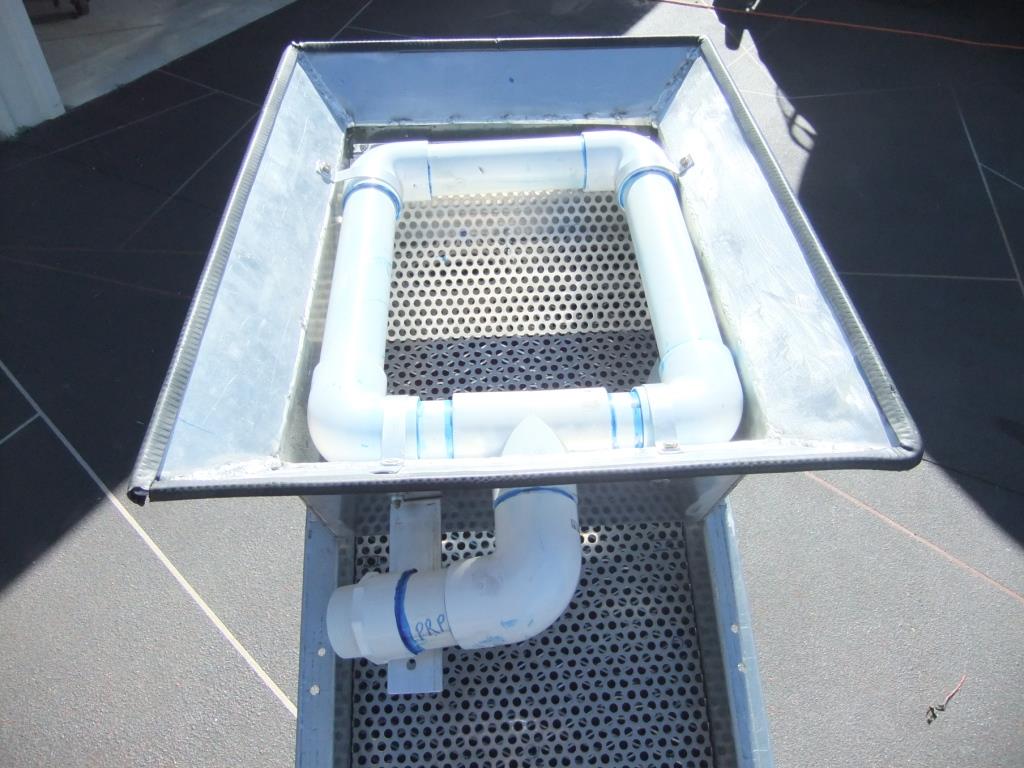

The spray nozzles in pics 5&6 are an experiment, in pic 3 I have the conventional sprays but if I use a trommel I rob my space in the box so I devised this idea and will give it a go, the shield on top of the nozzles is retractable.

I had in mind that I may be able to flatten out the nozzle water to be more spread rather than just a water blast? (watch this space)

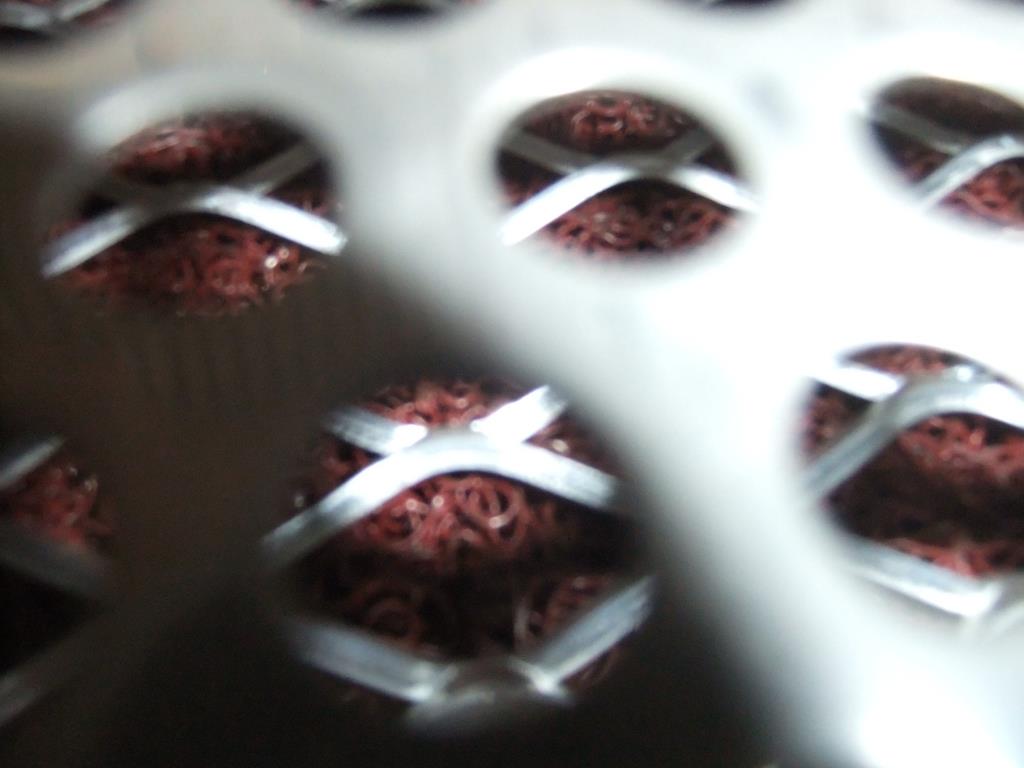

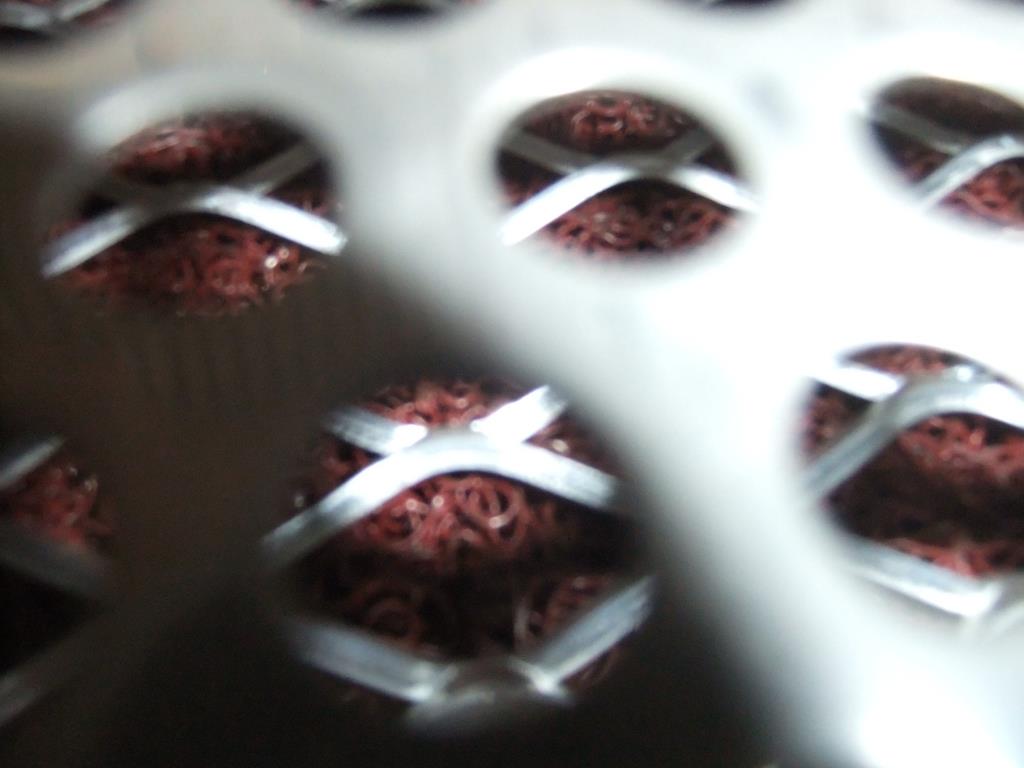

The sluice on the bottom is 300mm wide and I have incorporated the Gold Hog matting in various configurations, also experimenting with that one too.

I will pull apart the top sluice and reveal all there tomorrow,

Cheers guys and thanks for the wonderful encouragement.

I am having all sorts of issues with this gadget (Computer) my partner says it's got something to do with my age? bloody women, nothing like a wanna be comedian in the house!!

The spray nozzles in pics 5&6 are an experiment, in pic 3 I have the conventional sprays but if I use a trommel I rob my space in the box so I devised this idea and will give it a go, the shield on top of the nozzles is retractable.

I had in mind that I may be able to flatten out the nozzle water to be more spread rather than just a water blast? (watch this space)

The sluice on the bottom is 300mm wide and I have incorporated the Gold Hog matting in various configurations, also experimenting with that one too.

I will pull apart the top sluice and reveal all there tomorrow,

Cheers guys and thanks for the wonderful encouragement.

Some more pics.I have a plan B with both the catchment system and the spray system, the mesh in the top sluice will possibly clog up quite rapidly so I have on hand 1/2" mesh to swap with if need be.

As you can see this is backup 2 for the sprays. pics 2,3& 4 are looking down from the drop section of the bottom sluice, as you can see I am trying to cover all angles to capture any strays that might be missed in the top.

As you can see this is backup 2 for the sprays. pics 2,3& 4 are looking down from the drop section of the bottom sluice, as you can see I am trying to cover all angles to capture any strays that might be missed in the top.

TenOunce Tone

tony

If this does not get gold then you are digging in barren gravel!

Cheers, Tone

Cheers, Tone

slowflow

Barry

What a BEAST. That will get gold.

subgram

James

Really good looking machine!

hey goldslate looking good mate.

Your gunna hate me for saying this but I can foresee an issue for you, the type of punch plate your using requires horizontal water flow to clear properly and I cant see that any water will make its way onto the screen to clear rocks out the way for you.

The problem with punch plate is rocks fall into them and just sit there, unless there's upwards and sideways lift they clog quite easily.

I think you will be putting your hand under that hopper constantly trying to clear the small rocks out not that that's the end of the world i'm just speaking from experience it can get a bit painfull. think grass sticks rocks etc.

If you can get hold of some of this weave material in stainless it clears quite well even a small section to act as a ramp would help i think. if you get stuck i'm happy to cut you small piece and ship it to you.

Your gunna hate me for saying this but I can foresee an issue for you, the type of punch plate your using requires horizontal water flow to clear properly and I cant see that any water will make its way onto the screen to clear rocks out the way for you.

The problem with punch plate is rocks fall into them and just sit there, unless there's upwards and sideways lift they clog quite easily.

I think you will be putting your hand under that hopper constantly trying to clear the small rocks out not that that's the end of the world i'm just speaking from experience it can get a bit painfull. think grass sticks rocks etc.

If you can get hold of some of this weave material in stainless it clears quite well even a small section to act as a ramp would help i think. if you get stuck i'm happy to cut you small piece and ship it to you.

Hey Guys thanks for the likes, I am positive it will trap something?? might even throw it in the dam and chase yabbies hahaha,

But one thing I overlooked was the punch plate clogging and restricting water flow, Thanks GOLddig, as we speak, I will try to source some mesh like you have pictured. Cheers once again guys

New project at the moment is a portable fridge slide for the ute.

Goldslave

But one thing I overlooked was the punch plate clogging and restricting water flow, Thanks GOLddig, as we speak, I will try to source some mesh like you have pictured. Cheers once again guys

New project at the moment is a portable fridge slide for the ute.

Goldslave

Twapster

Peter

Impressive build, it should be called the Goldslaves "Gold Stopper"

Hi Goldslave, do you work in the metal industry and do your own aluminium welding? Cos it it looks a real "doozy".

Jaros said:Hi Goldslave, do you work in the metal industry and do your own aluminium welding? Cos it it looks a real "doozy".

and the pourpose of you saying that is?

Hi GolDDig,

I was looking at the Walbanker with the electrical tray type classifier AAAAAND" if I got out my trusty slotter and expanded the holes in the top section of my top sluice to have it looking something like the electrical tray material in the Walbanker, possibly for 300mm or so maybe that might save me some heartaches, maybe!!! whats your thoughts on that?

I will give it a try as it stands and will take my slotter with me and go to plan "B" if it gives me too much grief, I'll keep you posted.

Happy digging everyone, I'll be on the road we hope at the end of this week, Cheers

Goldslace

I was looking at the Walbanker with the electrical tray type classifier AAAAAND" if I got out my trusty slotter and expanded the holes in the top section of my top sluice to have it looking something like the electrical tray material in the Walbanker, possibly for 300mm or so maybe that might save me some heartaches, maybe!!! whats your thoughts on that?

I will give it a try as it stands and will take my slotter with me and go to plan "B" if it gives me too much grief, I'll keep you posted.

Happy digging everyone, I'll be on the road we hope at the end of this week, Cheers

Goldslace

Could be worth a try mate, the benefit of the cable tray pattern is the fast sections in between opening so your material gets washed and accelerates down the plate. You might get away with just fitting an extra spray bar inside your unit to flush material away form the gap?

at the end of the day mate you ahve the tools play away

at the end of the day mate you ahve the tools play away

one other 'positive supportive suggestion' is the spray bar inside the hopper might get smashed by rocks

i have a similar thing except the spray bar PVC pipes are further out at the outside of your sloping hungry boards and covered with 2 mm Ali sheet so the PVC pipe doesnt get schmacko'd .

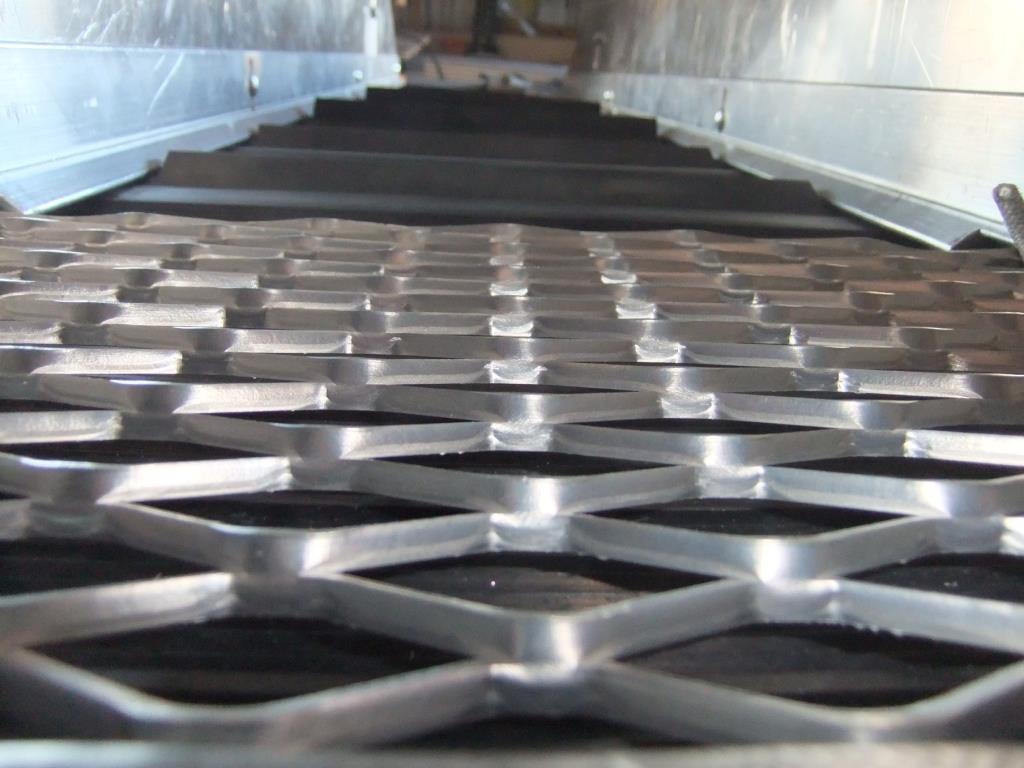

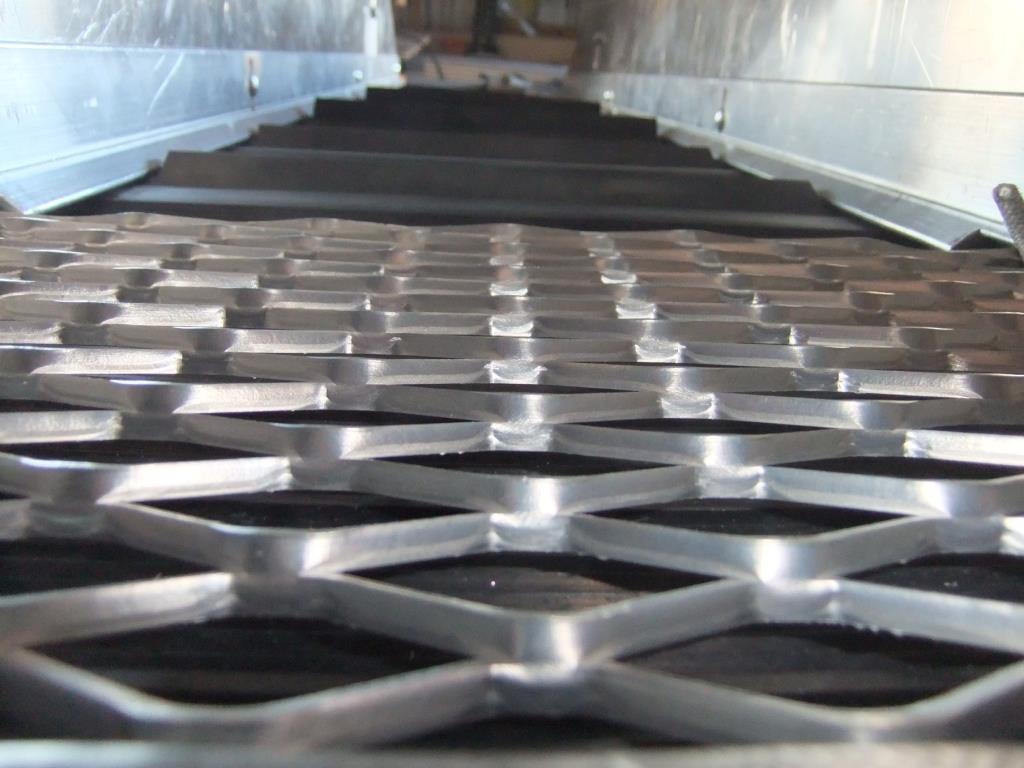

I have experimented with a few different styles of grizzly mesh , the one that clears fastest is parallel 12 x 3 mm flat bars with 8 or 13 mm gaps between them , i choose either one dependant on the type of gold where i am on the day , HOWEVER , that style of grizzly can also allow long thin spears to drop through and go through your sluice and they can sometimes create turbulance eddies which can pull fine gold out of your riffles , to avoid that i sometimes use perf mesh with either 8 or 13 mm holes , again dependant on where i am working with it .

those small PVC pipes can be heated up with a hot air gun and squashed down to an oval slit for wider spray jet

you cant quite see in the photo but those ali angles on top have PVC pipe spray bars running around underneath them on 4 sides

i have a similar thing except the spray bar PVC pipes are further out at the outside of your sloping hungry boards and covered with 2 mm Ali sheet so the PVC pipe doesnt get schmacko'd .

I have experimented with a few different styles of grizzly mesh , the one that clears fastest is parallel 12 x 3 mm flat bars with 8 or 13 mm gaps between them , i choose either one dependant on the type of gold where i am on the day , HOWEVER , that style of grizzly can also allow long thin spears to drop through and go through your sluice and they can sometimes create turbulance eddies which can pull fine gold out of your riffles , to avoid that i sometimes use perf mesh with either 8 or 13 mm holes , again dependant on where i am working with it .

those small PVC pipes can be heated up with a hot air gun and squashed down to an oval slit for wider spray jet

you cant quite see in the photo but those ali angles on top have PVC pipe spray bars running around underneath them on 4 sides

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 1

- Views

- 297