thesmithy

Brian Rourke

- Joined

- Apr 20, 2013

- Messages

- 315

- Reaction score

- 195

Hey All

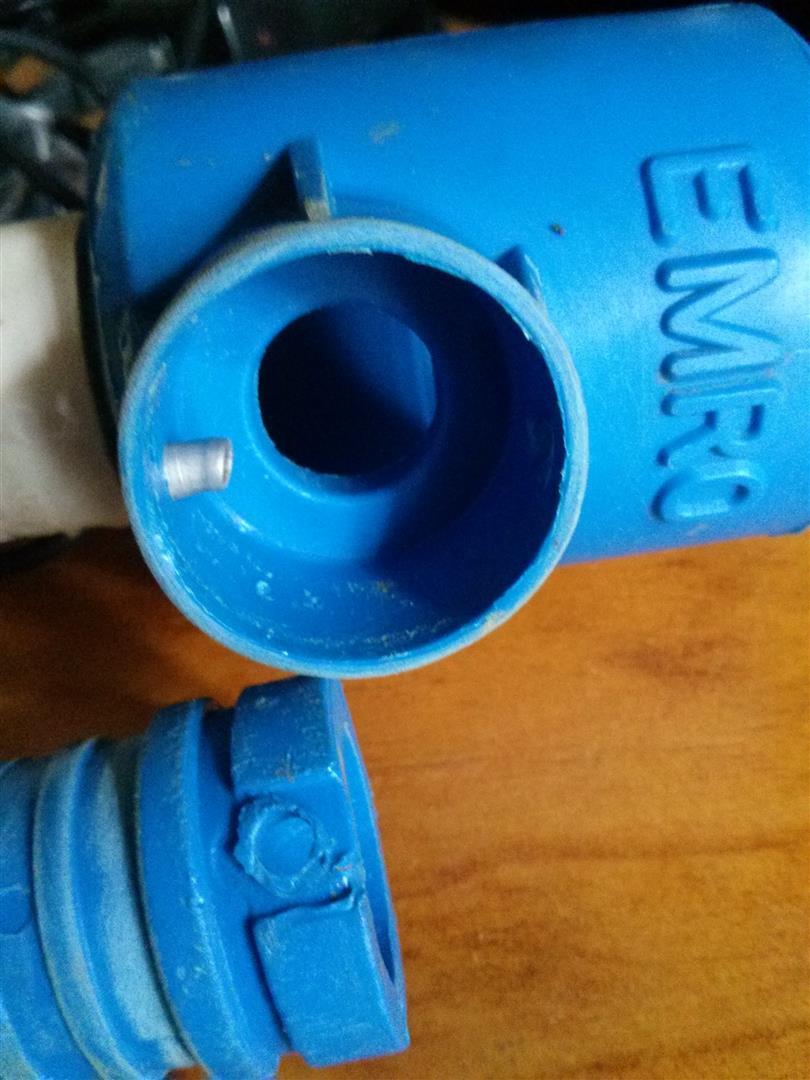

Here is a new item that you can add to the collection of crevicing implements.

it attaches to the bottom of most Yabby pumps.

On draw back it opens flap on the bottom 20 mm max opening.

when the handle is pushed back again it closes bottom flap and opens side flap.

just add clear hose to it and a very reliable sucker is created.

when finished it converts back to a Yabby pump.

Cab be purchased at BIAS Boating in any state for around $25.00

for those of us that are mechanically minded you can cut down the Yabby pump to make a shorty.

Not all Yabby pumps are the same diameter so take a measurement with you.

have a look at the pics.

Cam handle rolls over to lock on to pump

side view very easy to fit on to pump

see rubber flap inside will certainly clean up crevices with clear hose attached

Attached to pump

cheers

TheSmithy

Here is a new item that you can add to the collection of crevicing implements.

it attaches to the bottom of most Yabby pumps.

On draw back it opens flap on the bottom 20 mm max opening.

when the handle is pushed back again it closes bottom flap and opens side flap.

just add clear hose to it and a very reliable sucker is created.

when finished it converts back to a Yabby pump.

Cab be purchased at BIAS Boating in any state for around $25.00

for those of us that are mechanically minded you can cut down the Yabby pump to make a shorty.

Not all Yabby pumps are the same diameter so take a measurement with you.

have a look at the pics.

Cam handle rolls over to lock on to pump

side view very easy to fit on to pump

see rubber flap inside will certainly clean up crevices with clear hose attached

Attached to pump

cheers

TheSmithy