Moneybox

Philip & Sandra Box

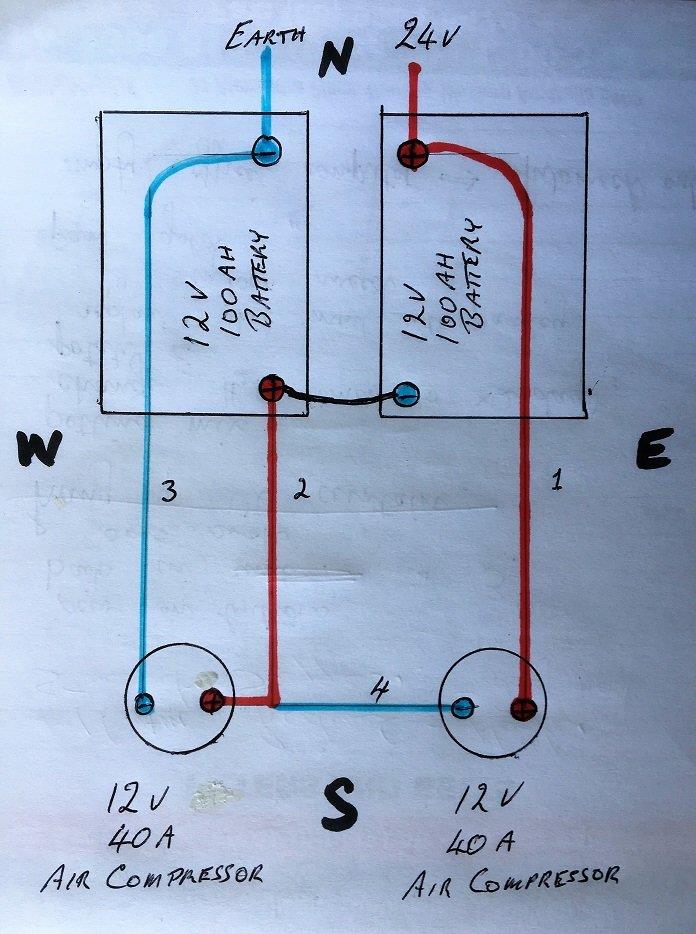

I have a 24v electrical system in my vehicle. When I purchased my two 3.5 cfm compressors I could only get them in 12v. Each compressor draws a maximum 40A.

To simplify the diagram it does not show the related switches and relays. I've marked the illustration N,S,E and W.

Q1, What is the direction of current flow in each cable 1, 2, 3 and 4

Q2, When the compressors are drawing their maximum draw, what is the current draw on each cable 1, 2, 3 and 4

Q3, If one cable differs from the others explain why

To simplify the diagram it does not show the related switches and relays. I've marked the illustration N,S,E and W.

Q1, What is the direction of current flow in each cable 1, 2, 3 and 4

Q2, When the compressors are drawing their maximum draw, what is the current draw on each cable 1, 2, 3 and 4

Q3, If one cable differs from the others explain why