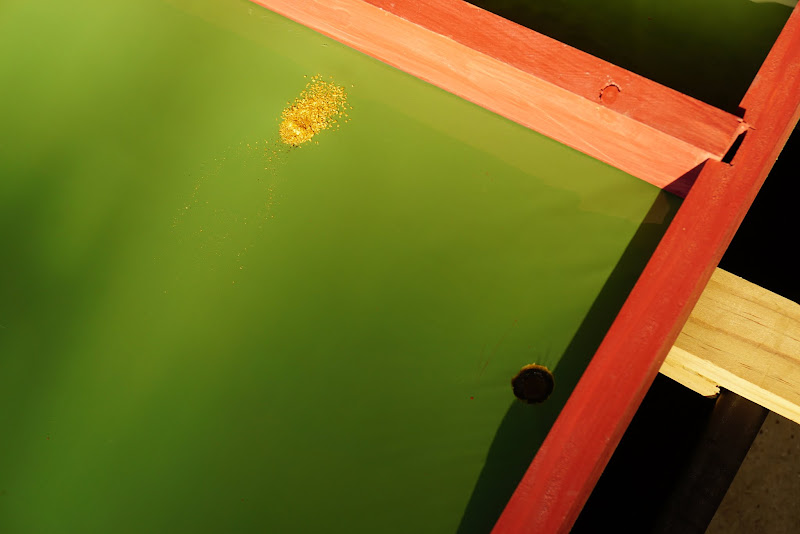

Got some cons ready to run through mini sluice or pan is there an easy way of washing the silt out to keep the recirculating water clean without loosing any gold powder as one day I plan to blue bowl all my tailings to recover the microscopic gold ?

I have tried trickling water up through my cons but still found gold specks in the wash off water.

Seen videos of blue bowls running clean so there must be a way and is silt in my cons a sign I don't run enough water over the sluice in the first place ?

I have tried trickling water up through my cons but still found gold specks in the wash off water.

Seen videos of blue bowls running clean so there must be a way and is silt in my cons a sign I don't run enough water over the sluice in the first place ?