- Joined

- Jul 25, 2021

- Messages

- 278

- Reaction score

- 342

Sandbagger said:PabloP said:Sandbagger said:Phil8303 said:Too right, Baz! You have to stay engaged in something. For me, it's multiple things (prospecting, woodwork, photography and more).

Mate, given you're an engineer, can I ask if you have any advice on how I might build my own rock tumbler?

I actually read that as trommel for some reason.

Rock tumbler: 100mm PVC pipe and end caps, three blocks of pine, a drill and a lacky band. Go from there.

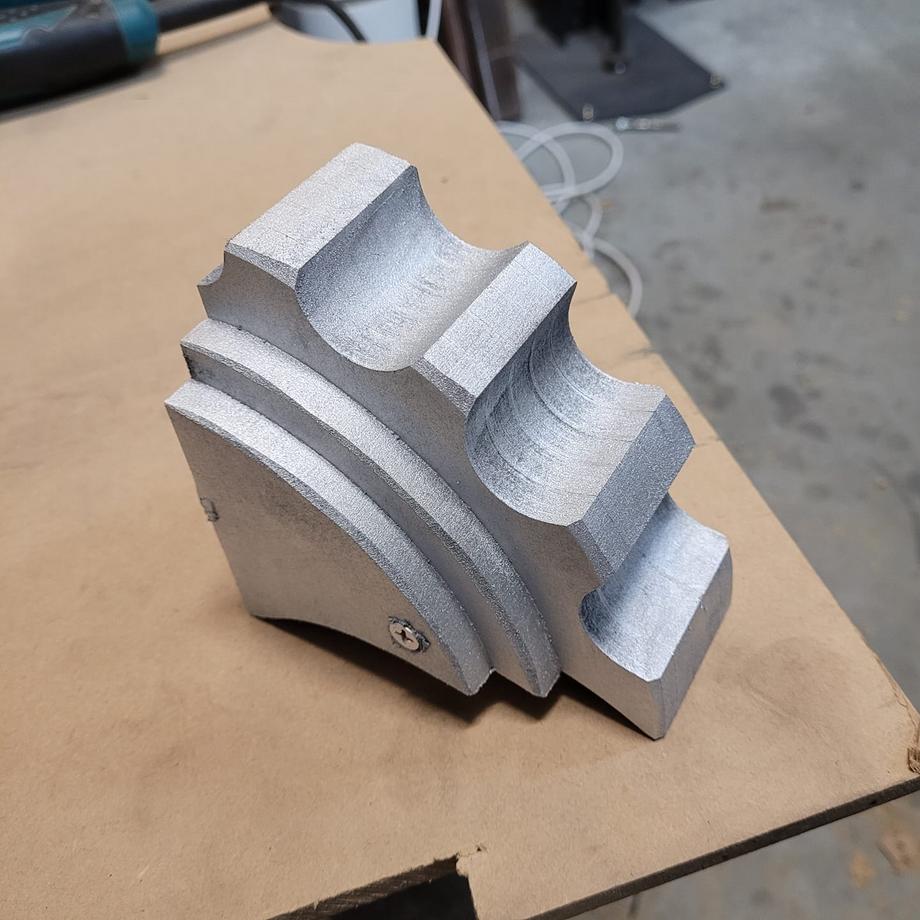

https://i.imgur.com/peoi40z.jpg?1

I like your "have a go attitude", but the Ozito wouldn't last for long as they have a very low duty cycle and crap out very fast. But the Ozito or any drill would test the various ideas out fine.

Rob P.

I've had my ozito for years and it's outlasted my bosch, dewalt and makita tools. Had as black and decker from bunnings once, that lasted me 25 years.

I've got an old corded Ozito and a new Bosch drill, but was gonna try the Ozito in a prototype version. The Mrs buys fish oil in those plastic tubs (about 20cm in diameter) that I reckon could work for a test.