Hi all.

Long time no post.

I hope the hunts have been prosperous for you all!

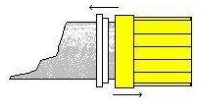

Does anyone have any idea of how to remove and install one of the Minelab GPX series shaft twist locks?

The part you rotate to tighten the lower shaft to the upper shaft.

The part number is 8008-0002, or alternatively 124947, and is available from MinersDen, Dick Smith, and some other online sellers for $14.20 AUD plus postage.

An older post on this forum also mentioned Nenad from PhaseTechnical and Coiltek in Maryborough, Vic, also sells them.

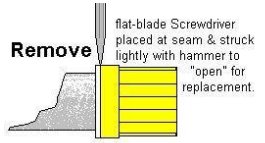

I cannot work out how to remove the old one, or install the new one?

I assumed it would be straight forward, but apparently, to me so far at least, its not.

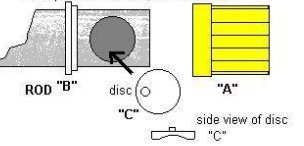

The bottom ring will need to be glued to the main part once its actually on the shaft, but installing the small rounded bit, and getting the main part over that piece, has me stumped.

Any suggestions greatly appreciated.

Long time no post.

I hope the hunts have been prosperous for you all!

Does anyone have any idea of how to remove and install one of the Minelab GPX series shaft twist locks?

The part you rotate to tighten the lower shaft to the upper shaft.

The part number is 8008-0002, or alternatively 124947, and is available from MinersDen, Dick Smith, and some other online sellers for $14.20 AUD plus postage.

An older post on this forum also mentioned Nenad from PhaseTechnical and Coiltek in Maryborough, Vic, also sells them.

I cannot work out how to remove the old one, or install the new one?

I assumed it would be straight forward, but apparently, to me so far at least, its not.

The bottom ring will need to be glued to the main part once its actually on the shaft, but installing the small rounded bit, and getting the main part over that piece, has me stumped.

Any suggestions greatly appreciated.