You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bellows Dry Washer Build

- Thread starter Dave63

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dave,

Best advice is you set your dry blower up at home on a level floor, adjust the legs to set the riffle box/tray up at a 21 angle.

After you have done this, buy a two way bubble spirit level (Caravan stores have them)eg; https://www.ebay.com.au/i/274249092...pOzzGpvmXBp7mK4pec41lFKwgXj70DXBoCAusQAvD_BwE

Now permanently fix this level to the frame of you dry blower so both bubbles are centered.

When you get to your dry blowing area it is now an easy and simple way to set up knowing your riffle tray is at the ideal angle of 21.

Be sure to purchase very tight weave cloth for your riffle tray, don't be conned into buying "constant air cloth" the weave is too open and the bellows suck dust through into the bellows chamber when it takes a breath.

Good luck.

Best advice is you set your dry blower up at home on a level floor, adjust the legs to set the riffle box/tray up at a 21 angle.

After you have done this, buy a two way bubble spirit level (Caravan stores have them)eg; https://www.ebay.com.au/i/274249092...pOzzGpvmXBp7mK4pec41lFKwgXj70DXBoCAusQAvD_BwE

Now permanently fix this level to the frame of you dry blower so both bubbles are centered.

When you get to your dry blowing area it is now an easy and simple way to set up knowing your riffle tray is at the ideal angle of 21.

Be sure to purchase very tight weave cloth for your riffle tray, don't be conned into buying "constant air cloth" the weave is too open and the bellows suck dust through into the bellows chamber when it takes a breath.

Good luck.

- Joined

- Oct 3, 2019

- Messages

- 1,120

- Reaction score

- 1,000

How much gold per 8 hours do you hope to recover ? In the good old days, I built a 3 inch dredge . An old guy at that time , I am the old guy now , was getting more gold than me , working with a pan and cleaning out cracks in the the creek bed . I was putting through more material but getting less return than what he was .

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

Mike678. I have no Idea. Depends on the ground. One of the blokes on this site says he doesn't stop test panning until he finds a spot where he thinks 1/2 oz in that time is possible.

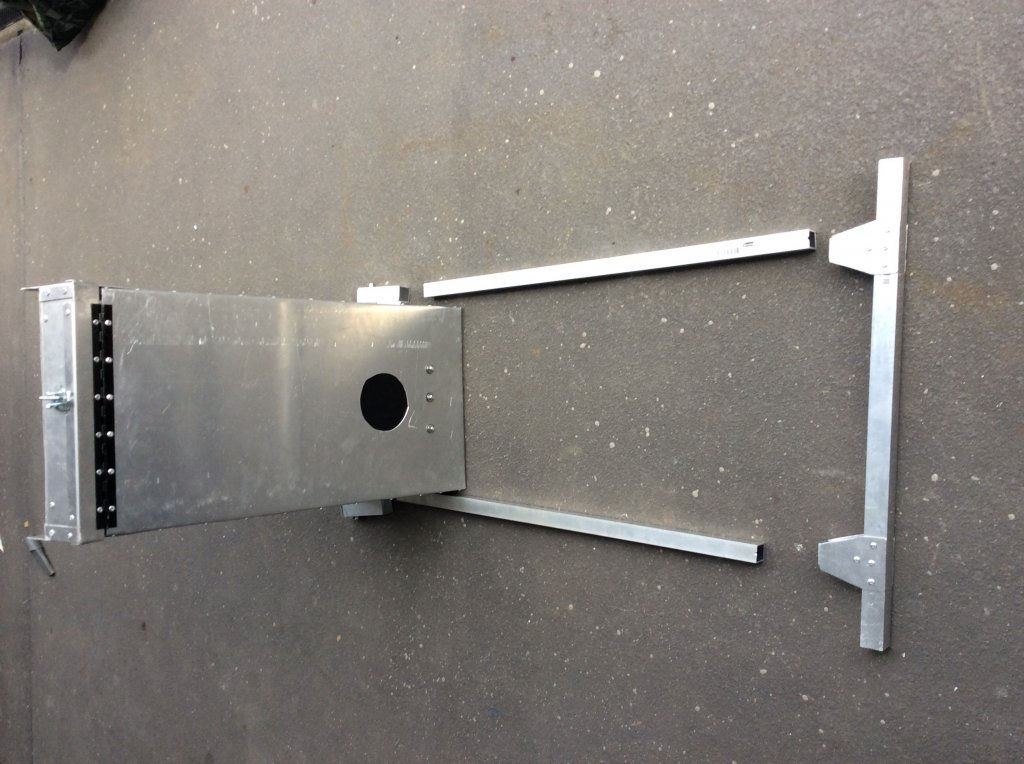

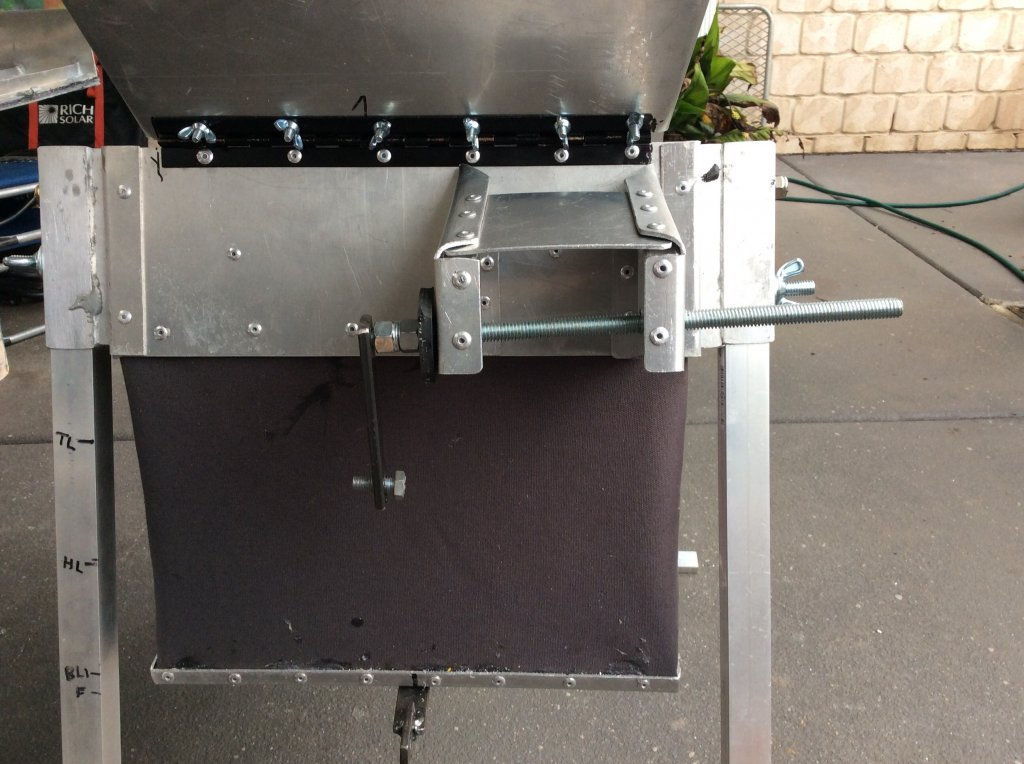

Todays build

Finished bellows and made rear legs

Tomorrow Finish Hopper and Attach hopper to Bellows and make Front legs

Set to angle of 21 degrees

Todays build

Finished bellows and made rear legs

Tomorrow Finish Hopper and Attach hopper to Bellows and make Front legs

Set to angle of 21 degrees

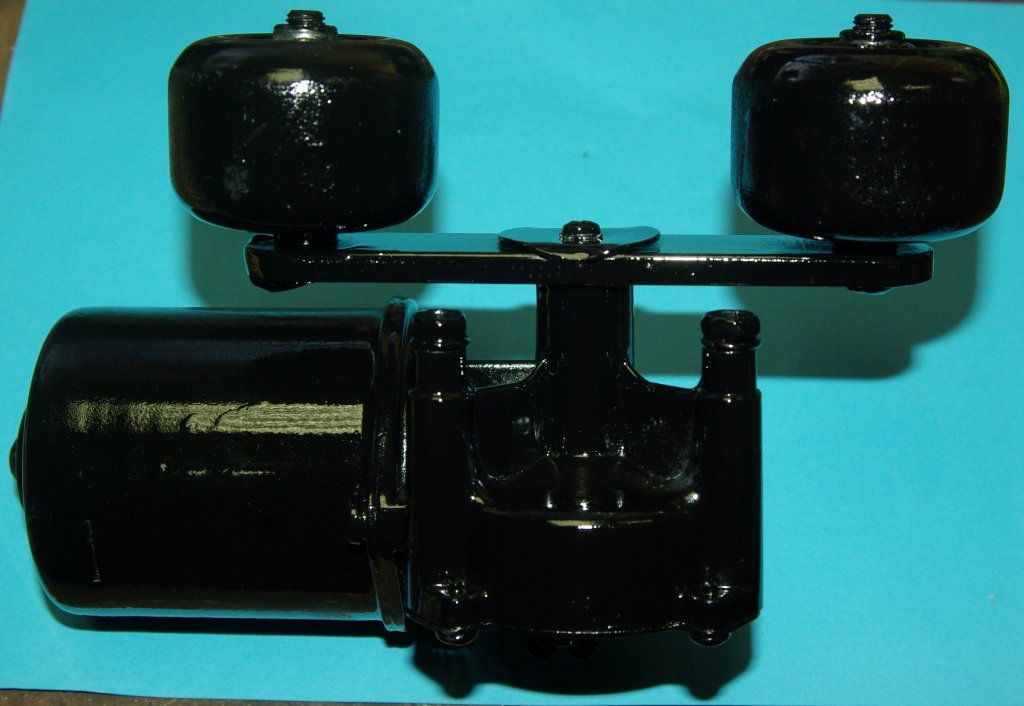

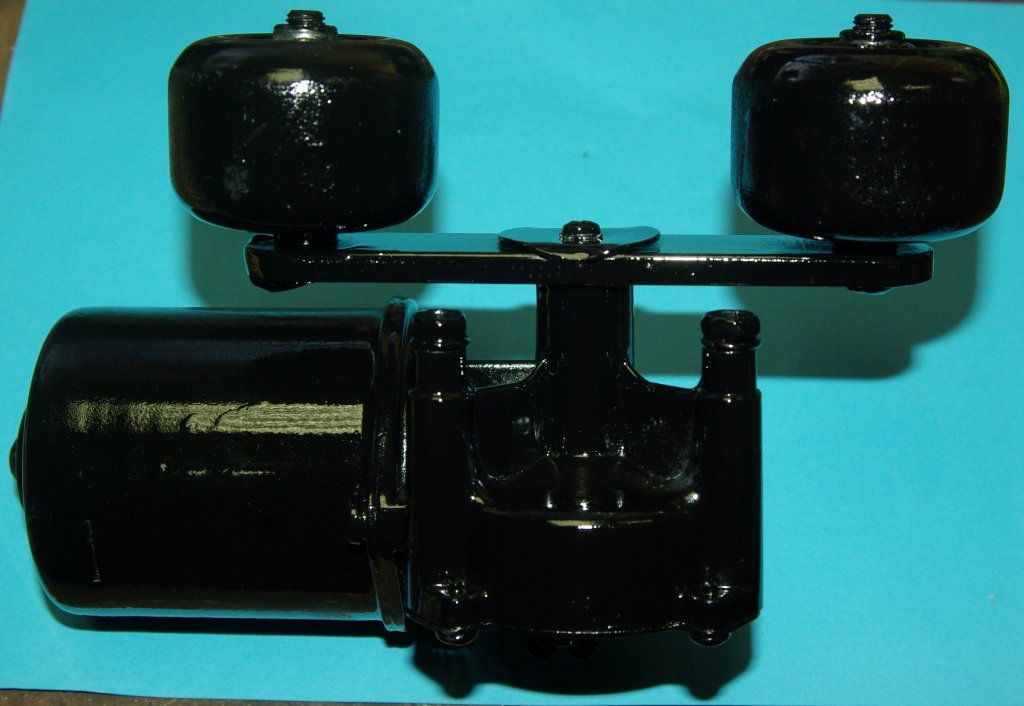

Dave,

You mentioned using a widscreen motor to drive your blower. Here are a few photos incorporating motor and wheels from a op shop skate board.

Hacksaw the the aluminium housing leaving the steel shaft then cut in half. Using a length of flat bar twice the length of bellows stroke mount the wheels either end. Hole in centre to fix to windscren motor.

You mentioned using a widscreen motor to drive your blower. Here are a few photos incorporating motor and wheels from a op shop skate board.

Hacksaw the the aluminium housing leaving the steel shaft then cut in half. Using a length of flat bar twice the length of bellows stroke mount the wheels either end. Hole in centre to fix to windscren motor.

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

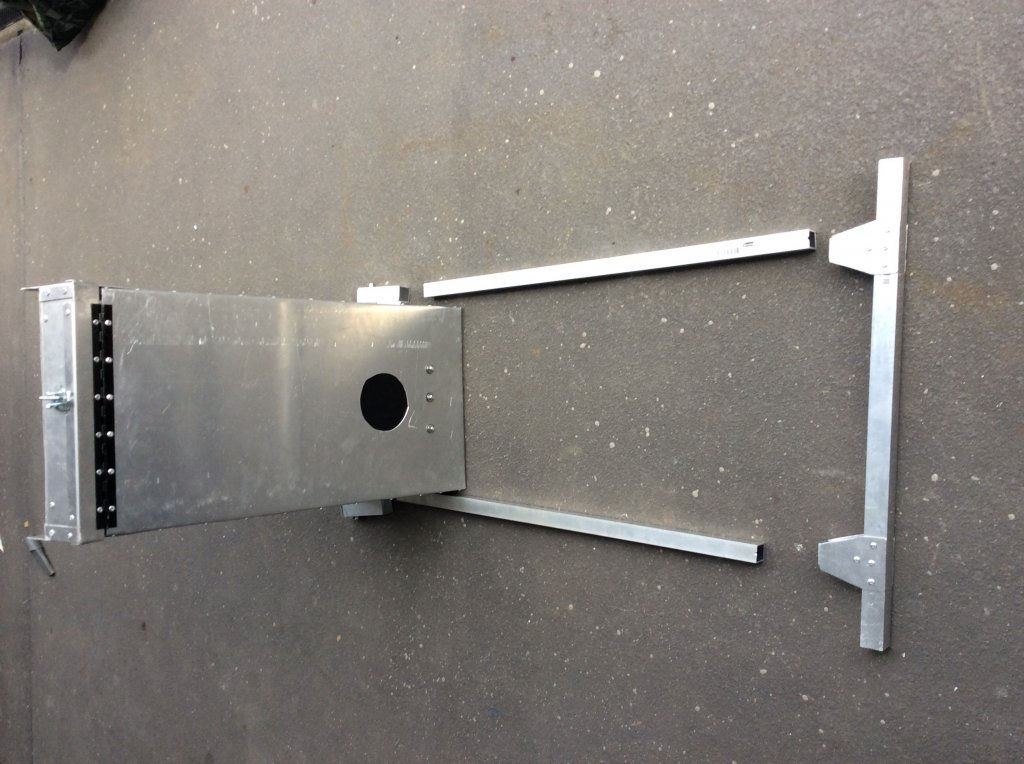

G'Day All

Starting to look like something now.

Today

Attached Hopper

Rear Legs mod add extra bolt to support better. (Removable to allow rear legs to be removed)

Front Legs added (Top part comes off to save space and pack up with hopper. Bottom half folds up under Bellows)

Tomorrow

Add Gate to Hopper opening

Close Air Gaps to Bellows Box

Make Support for Hopper Large rock shield

Make Front leg feet like at bottom of Rear legs

Disassemble Riffle tray to remove Dead air spots

To Do

Hand crank system

Motor Crank System

Test and Modify ( I will video 1st run so we can all share the laugh as it fall to bits ) :lol:

Cheers

Starting to look like something now.

Today

Attached Hopper

Rear Legs mod add extra bolt to support better. (Removable to allow rear legs to be removed)

Front Legs added (Top part comes off to save space and pack up with hopper. Bottom half folds up under Bellows)

Tomorrow

Add Gate to Hopper opening

Close Air Gaps to Bellows Box

Make Support for Hopper Large rock shield

Make Front leg feet like at bottom of Rear legs

Disassemble Riffle tray to remove Dead air spots

To Do

Hand crank system

Motor Crank System

Test and Modify ( I will video 1st run so we can all share the laugh as it fall to bits ) :lol:

Cheers

Nice work.

Looking good

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

G'Day All

Has been raining here for over a week. I am making a Dry Washer :/

:/

Today

Made front Feet

Added Fabric to bellows to cover Hinge gap and Added more silicon

Attach Hopper Gate

Attached Bellows Latch

Started Manual Bellows Crank

Over all it was a make it up as I go day. Wait it has been from the start

Tomorrow Continue with Hand Crank

Cheers

Has been raining here for over a week. I am making a Dry Washer

Today

Made front Feet

Added Fabric to bellows to cover Hinge gap and Added more silicon

Attach Hopper Gate

Attached Bellows Latch

Started Manual Bellows Crank

Over all it was a make it up as I go day. Wait it has been from the start

Tomorrow Continue with Hand Crank

Cheers

Goldtarget

(AKA OldGT)

Cant wait to see you fire the Beasty up, looking schmiko mate. And just in time for sluicing season :Y:  erfect:

erfect:

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

G'Day All

Didn't get much done today All fiddly stuff

Might have to rebuild Riffle tray. Took it to bit to remove dead air zone, put it back together now it doesn't fit properly Bit of grinding tomorrow might fix it. If not pull it completely to pieces and start again. :awful:

Bit of grinding tomorrow might fix it. If not pull it completely to pieces and start again. :awful:

Also today started manual hand crank. Bit crooked I can fix this.

Tomorrow fit Riffle tray

Hand crank

Cheers All

Didn't get much done today All fiddly stuff

Might have to rebuild Riffle tray. Took it to bit to remove dead air zone, put it back together now it doesn't fit properly

Also today started manual hand crank. Bit crooked I can fix this.

Tomorrow fit Riffle tray

Hand crank

Cheers All

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

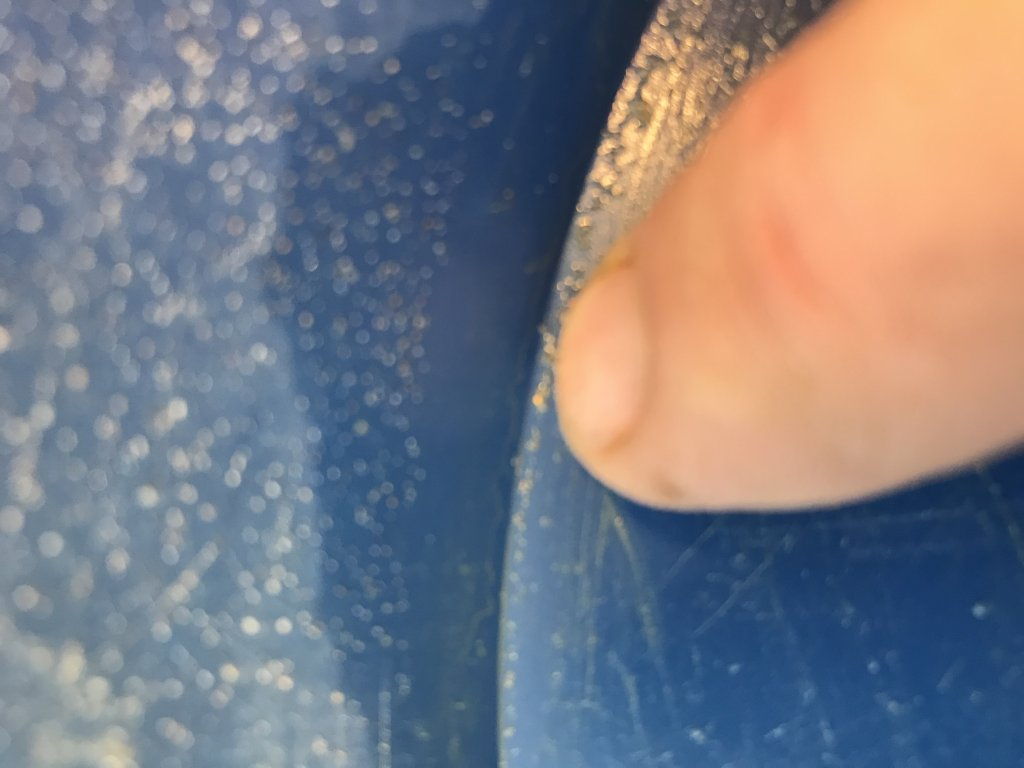

[video=480,360]https://www.youtube.com/watch?v=eUvkBXHpE7c[/video]G'Day All

Finished Hand crank today First run :goldnugget: Gold :clap:

Ran some pay dirt from Durikai GPA through the Dry washer.

Found two micro specks of gold. :goldpan: :goldnugget:

I have to run all that dirt through recirculating sluice now to see if there is more.

I video the run on my phone still trying to figure out how to get it onto Youtube

Gold at end of Pop Rivet and End of my finger.

Need to add Silk Screen fabric 200 Mesh as Nightjar said a lot of fine dust in bellows box.

Need to mount Motor now

Cheers

Finished Hand crank today First run :goldnugget: Gold :clap:

Ran some pay dirt from Durikai GPA through the Dry washer.

Found two micro specks of gold. :goldpan: :goldnugget:

I have to run all that dirt through recirculating sluice now to see if there is more.

I video the run on my phone still trying to figure out how to get it onto Youtube

Gold at end of Pop Rivet and End of my finger.

Need to add Silk Screen fabric 200 Mesh as Nightjar said a lot of fine dust in bellows box.

Need to mount Motor now

Cheers

Dave,

Great piece of workmanship and you have the videos under control.

You have some changes to make other that what you already mentioned.

1: Your top hopper should have had a flat bottom so the feed is spread evenly as it drops onto the riffles. (You're mixing wet sluicing with dry blowing with your set up.) A dry blower correctly set up catches 90% of the gold in top two riffles.

2: As you mentioned the machine must be set up level crosswise. Feel certain you lost gold over the end of the riffles, it was definitely overloaded. While it is puffing you

should be able to see the outline of each riffle just covered in pay dirt.

3: Your bellows seems to be puffing sufficiently however towards the end of the video air was puffing dust way back from upside of riffles? At the end of your run there was

far too much dirt packed up on the upside. The slots below the cloth should be puffing air directly behind the upside of each riffle. Don't know the dimension of your dry

blower but would guess at the end of your run you should have no more than about one litre of dirt left on the riffle tray.

4: Finally a sure way to test your dry blower is to add a number of tiny pieces of lead to your pay dirt. Shot gun pellet (2mm) size are ideal. Do a run and when you return 9/10 your machine is ready for real action.

Good luck.

Peter

Great piece of workmanship and you have the videos under control.

You have some changes to make other that what you already mentioned.

1: Your top hopper should have had a flat bottom so the feed is spread evenly as it drops onto the riffles. (You're mixing wet sluicing with dry blowing with your set up.) A dry blower correctly set up catches 90% of the gold in top two riffles.

2: As you mentioned the machine must be set up level crosswise. Feel certain you lost gold over the end of the riffles, it was definitely overloaded. While it is puffing you

should be able to see the outline of each riffle just covered in pay dirt.

3: Your bellows seems to be puffing sufficiently however towards the end of the video air was puffing dust way back from upside of riffles? At the end of your run there was

far too much dirt packed up on the upside. The slots below the cloth should be puffing air directly behind the upside of each riffle. Don't know the dimension of your dry

blower but would guess at the end of your run you should have no more than about one litre of dirt left on the riffle tray.

4: Finally a sure way to test your dry blower is to add a number of tiny pieces of lead to your pay dirt. Shot gun pellet (2mm) size are ideal. Do a run and when you return 9/10 your machine is ready for real action.

Good luck.

Peter

- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

I think I will make a different Hopper gate That spreads the dirt across the first riffle. Video didn't show it but I had a large minelab pan half full of material left.

I shoveled the already processed dirt back it and it ran ok. I did put two pieces of lead in big bits, I got them back. I also put 4 shootie pellets still to find those. I will make some mods and run again. Need more dry dirt from somewhere. MY riffles are 4" apart Might need to be closer together

I shoveled the already processed dirt back it and it ran ok. I did put two pieces of lead in big bits, I got them back. I also put 4 shootie pellets still to find those. I will make some mods and run again. Need more dry dirt from somewhere. MY riffles are 4" apart Might need to be closer together

G

Guest

Out of curiosity ,what would it go like if you hook it up to an variable cordless drill?

I,m guess you are trying to stay within the boundaries/law of not being an electric device?

But out in the never never you would get away with it??

I,m guess you are trying to stay within the boundaries/law of not being an electric device?

But out in the never never you would get away with it??

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 8

- Views

- 5K

- Replies

- 55

- Views

- 16K

- Replies

- 7

- Views

- 2K