Hello,

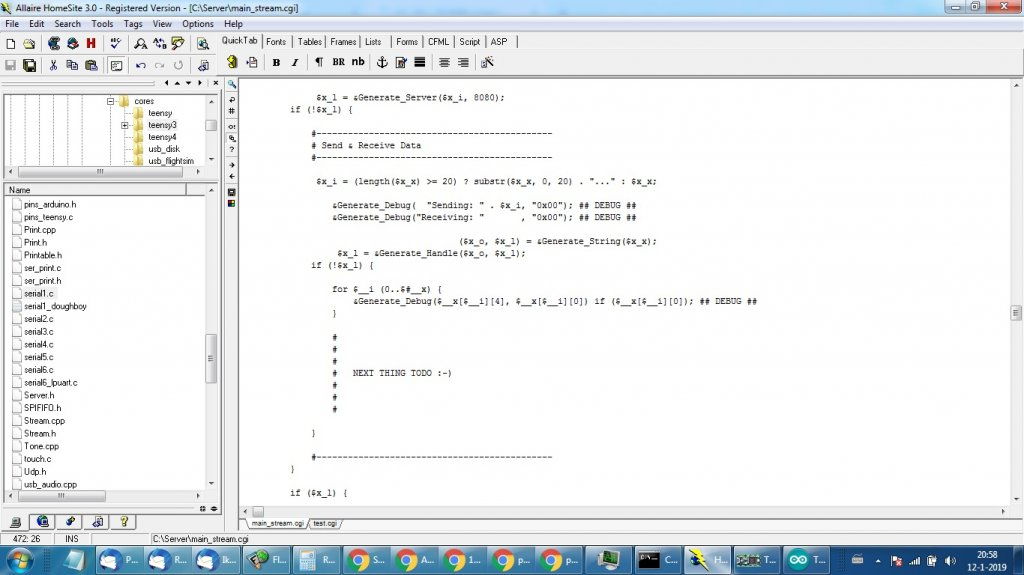

Yes, redoing my complete programming :- ) Again! lol, i came along something what i didnt thougth about earlier... And thats is continuous execution of the functions. So im already programming for two weeks now to write a function server. This server executes all commands that i give the server and the server can route all the commands so that i can write little functions for it like goto position x and grap lap 200 grid en contineu cutting :- ) al those sort of little functions can be easely executed then. Also started to program the motors but together with the server. Its again more then i wanted but it should be a nice feature in the future! It will say if i want to add a motor or i want to get some pneumatics in it can be done in a few clicks. Also something nice is that i can interact between cutting, pause the machine, stop the machine and contineu the next day etc etc etc.

And the laps are fine didnt had any time to look to them closeley but they are oke!

Greets,

Christian

PS:

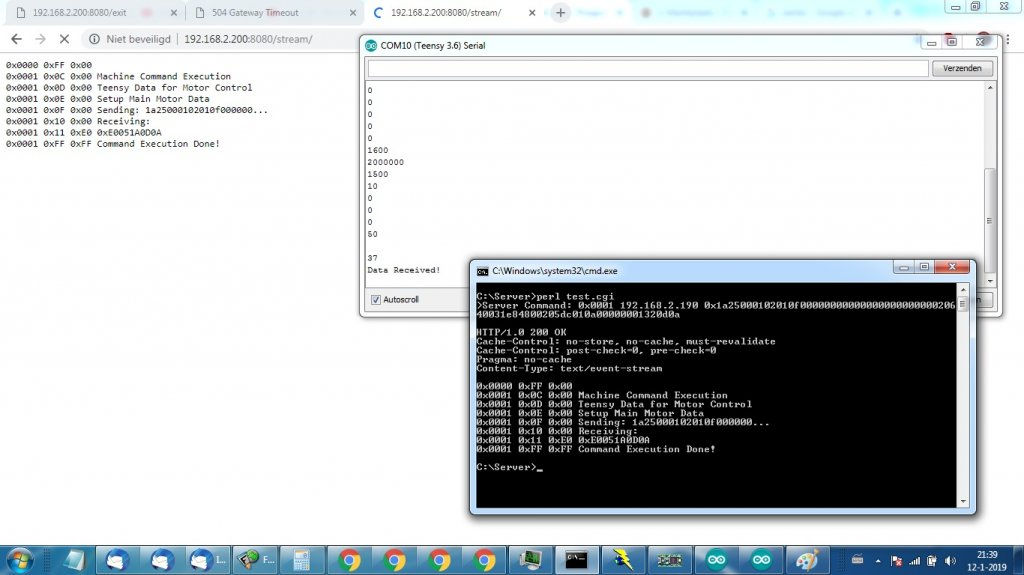

Uhm Lets do an example:

C:\Server>perl test.cgi

>Server Command: 0x0001 192.168.2.190 0x1b25000102010f0000000000000000000000020640031e84800205dc010a00000001320d0a

HTTP/1.0 200 OK

Cache-Control: no-store, no-cache, must-revalidate

Cache-Control: post-check=0, pre-check=0

Pragma: no-cache

Content-Type: text/event-stream

0x0000 0xFF 0x00

0x0001 0x01 0x00 Machine Command Execution

0x0001 0x02 0x00 Teensy Data for Motor Control

0x0001 0x03 0x00 Command Doesn't Exist! Mayby! Yet?

0x0001 0x04 0x00 Sending: 1b25000102010f000000...

0x0001 0x05 0x00 Receiving:

0x0001 0x06 0xEE EE051B0D0A

0x0001 0xFF 0xFF Command Execution Done!

C:\Server>

What you see is that im giving the server a setup command for the motor microcontroller the server (running at at the background) the server is handeling the command im giving. I can send a complete list of commands and the server is executing the commands to the right microcontroller. Above is just one command. It also means when i use the database instead sending loose comands i could turn off my computer :- ) but the machine is still doing its thing till its done or when it is paused.

Mayby not that readeble for you but at the end its for me verry easy to controll the machine without programming. Its becomming so easy that i can say: X axis you need to goto position 200mm. Or change lap to grid 800 or or or... etc