You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

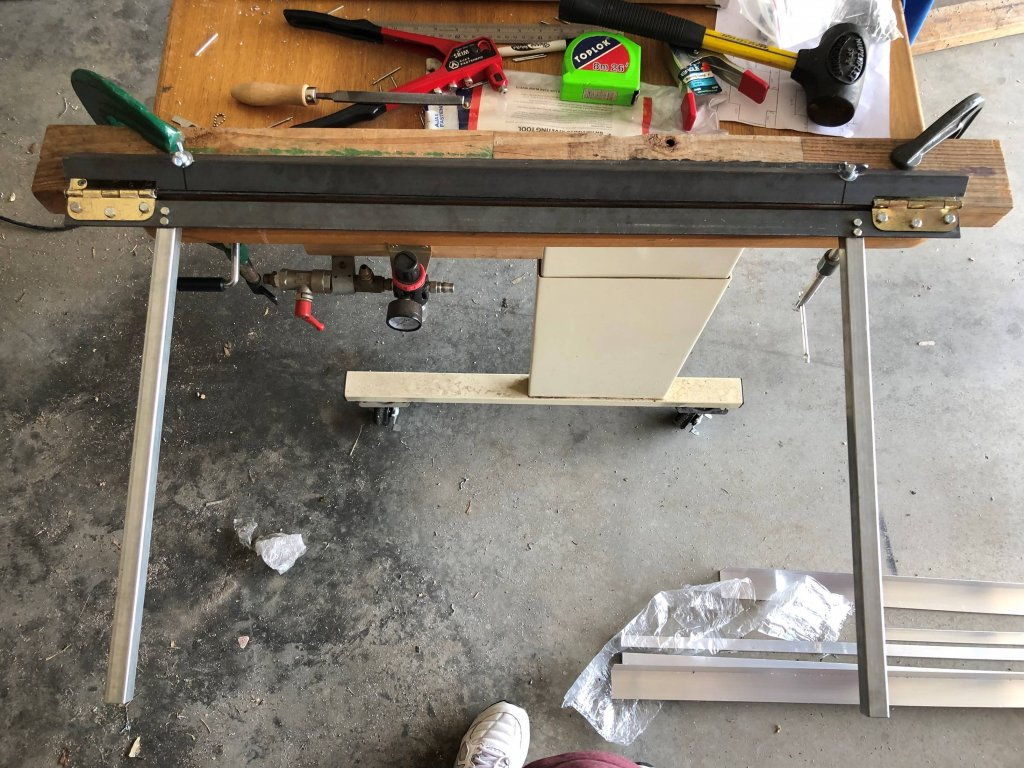

My attempt at a dry blower

- Thread starter max power

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Yes please upload pics. I love seeing DIY's put up here

Looking the goods. The rig you made to fold the sheets is a great idea

max power

joe

- Joined

- May 4, 2014

- Messages

- 64

- Reaction score

- 101

1968falconxt said:Looking the goods. The rig you made to fold the sheets is a great idea

thanks found it on youtube.

I think I'll make a bigger version and weld it.

What size is that dry blower riffle box? How high are your riffles?

max power

joe

- Joined

- May 4, 2014

- Messages

- 64

- Reaction score

- 101

The box is 450mm x 600mm x 150mm the ruffles are 20mm1968falconxt said:What size is that dry blower riffle box? How high are your riffles?

- Joined

- Nov 3, 2013

- Messages

- 109

- Reaction score

- 126

Hello Max, Could you attach a link to you metal press. I'm interested in folding one as well.

regards, Ned

regards, Ned

Ship of fools

Mat. T

Good work Max.

Matt T

Matt T

It looks like you have quite an aggressive angle on the riffles. I would run 90deg for the first few riffles, it helps with the material flow. I would also recommend changing the riffle height to 15mm. This suggestion was made to me after I built mine. I made the change and it worked better.

Also, if you haven't done so already you'll need to order some Keene dry blower cloth from Reeds Prospecting in WA. It can take a while to arrive after ordering.

Also, if you haven't done so already you'll need to order some Keene dry blower cloth from Reeds Prospecting in WA. It can take a while to arrive after ordering.

max power

joe

- Joined

- May 4, 2014

- Messages

- 64

- Reaction score

- 101

[video=480,360]https://youtu.be/qOdRej3579M[/video]Ned said:Hello Max, Could you attach a link to you metal press. I'm interested in folding one as well.

regards, Ned

[video=480,360]https://youtu.be/fJ5LZEYyjiU[/video]

max power

joe

- Joined

- May 4, 2014

- Messages

- 64

- Reaction score

- 101

Ok thanks falcon Ill make some changes on the weekend I have the cloth from Reeds on the way, whats the best way to attach it to the aluminium?1968falconxt said:It looks like you have quite an aggressive angle on the riffles. I would run 90deg for the first few riffles, it helps with the material flow. I would also recommend changing the riffle height to 15mm. This suggestion was made to me after I built mine. I made the change and it worked better.

Also, if you haven't done so already you'll need to order some Keene dry blower cloth from Reeds Prospecting in WA. It can take a while to arrive after ordering.

I also need to find something for the classifier.

Selley's liquid nails works well. Much easier than using a contact adhesive. Smear a light coat on the aluminium and the place the cloth over. Then just run your fingers all around and it should hold in place with no tape or anything

- Joined

- Nov 3, 2013

- Messages

- 109

- Reaction score

- 126

Hello Max,

Thanks for the links to the brake.

regards Ned

Thanks for the links to the brake.

regards Ned

max power

joe

- Joined

- May 4, 2014

- Messages

- 64

- Reaction score

- 101

PJG said:Hi Max. Just wondering how the dry blower project is going?

hi PJG not much has happened lately I have made some of changes that falcon suggested hopefully I'll get some time this weekend and I will post some more pics

Hi falcon i saw your dry blower design on diy forum awsome desing mate i was very inpressed probaly the best i have seen yet would apreciate any pics and dimensions you could share with me as my son and i are going to have a go at maki g our own also could you please show me pics and explain how you fixed your riffle cloth down and tensioned it apreciate any help you could give me cheers email [email protected]1968falconxt said:It looks like you have quite an aggressive angle on the riffles. I would run 90deg for the first few riffles, it helps with the material flow. I would also recommend changing the riffle height to 15mm. This suggestion was made to me after I built mine. I made the change and it worked better.

Also, if you haven't done so already you'll need to order some Keene dry blower cloth from Reeds Prospecting in WA. It can take a while to arrive after ordering.

Similar threads

- Replies

- 3

- Views

- 746

- Replies

- 8

- Views

- 3K