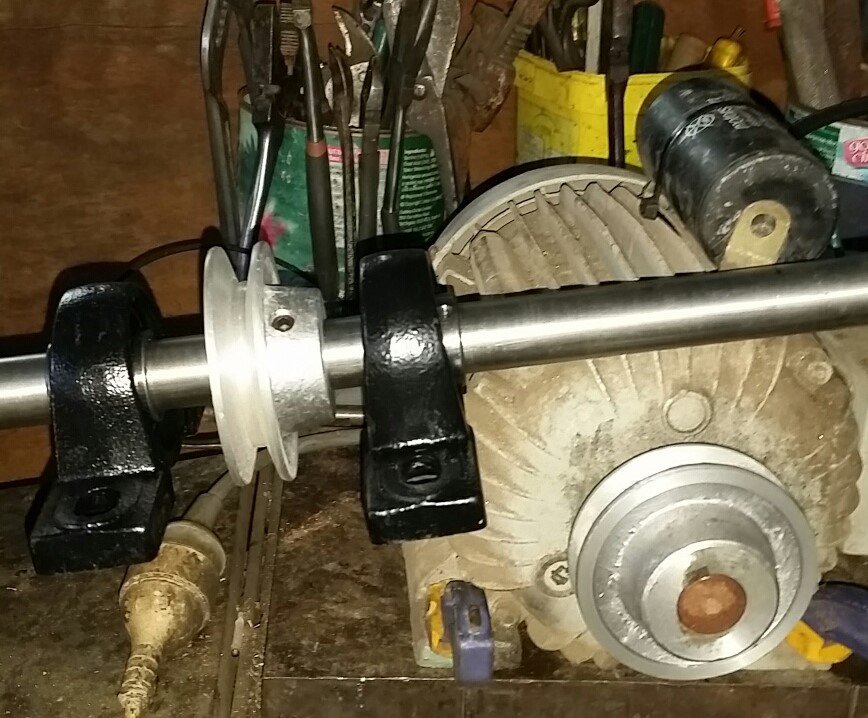

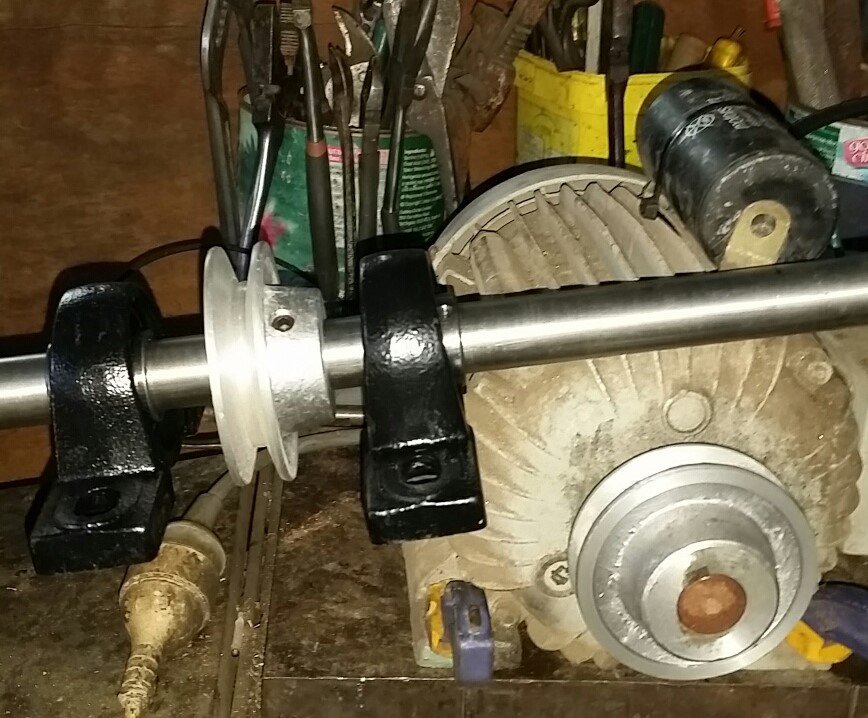

first progress on the cab grinder build . i have fixed a few probs with a motor i already had in the shed its a bit big but will do, its a 1hp off an old compressor . bought 2 pulleys and 2 bearings cos i wanted to use new ones . bored one pulley to suit the motor and cut a new keyway to suit ,bored the pulley to a nice fit on the 1"stainless shaft shaft , i like to buy them with a smaller arbor hole and machine my own , took the slight whoop out of the shaft .next i need to find out what is the norm for the ends of the shaft where a flat disc can be attached , is it stepped down in dia with a shoulder for the disc to register on or what . also what is the norm drill and tap in the ends of the shaft size for bolt or is the shaft end normally stepped down and threaded external thread for the end discs???.

i might get time to start making the frame work to mount it all on over the next few days .

johno

i might get time to start making the frame work to mount it all on over the next few days .

johno