- Joined

- Jan 2, 2017

- Messages

- 2,328

- Reaction score

- 3,015

I have experimented with this stuff for some years now, and I back it 100%.

But with modifications.

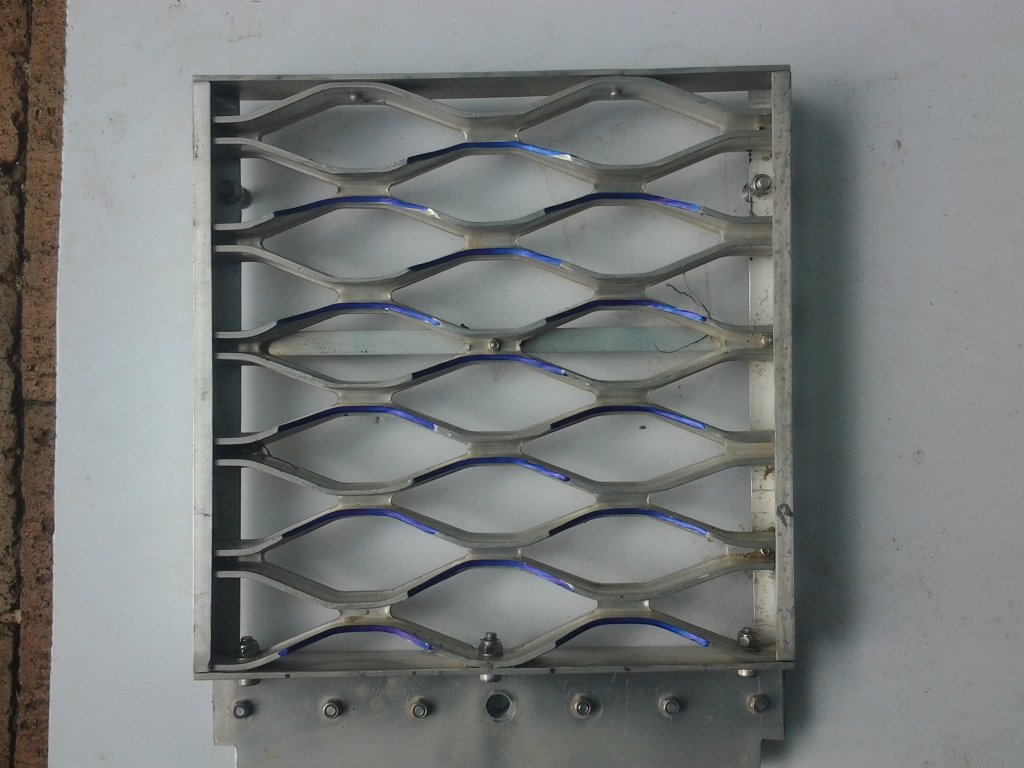

Firstly I use the 20mm cat walk mesh as opposed to the 12mm.

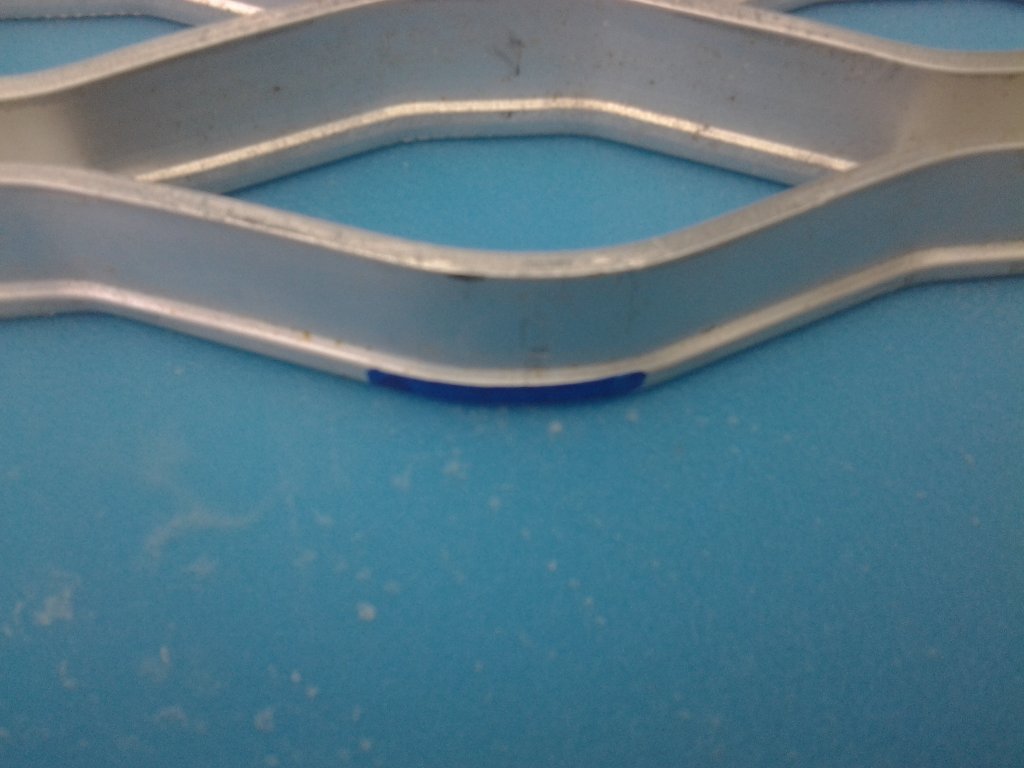

Scalloping the high side of the webs really helps a good turbulence in the baffle principal, takes a bit of time to do but very needed.

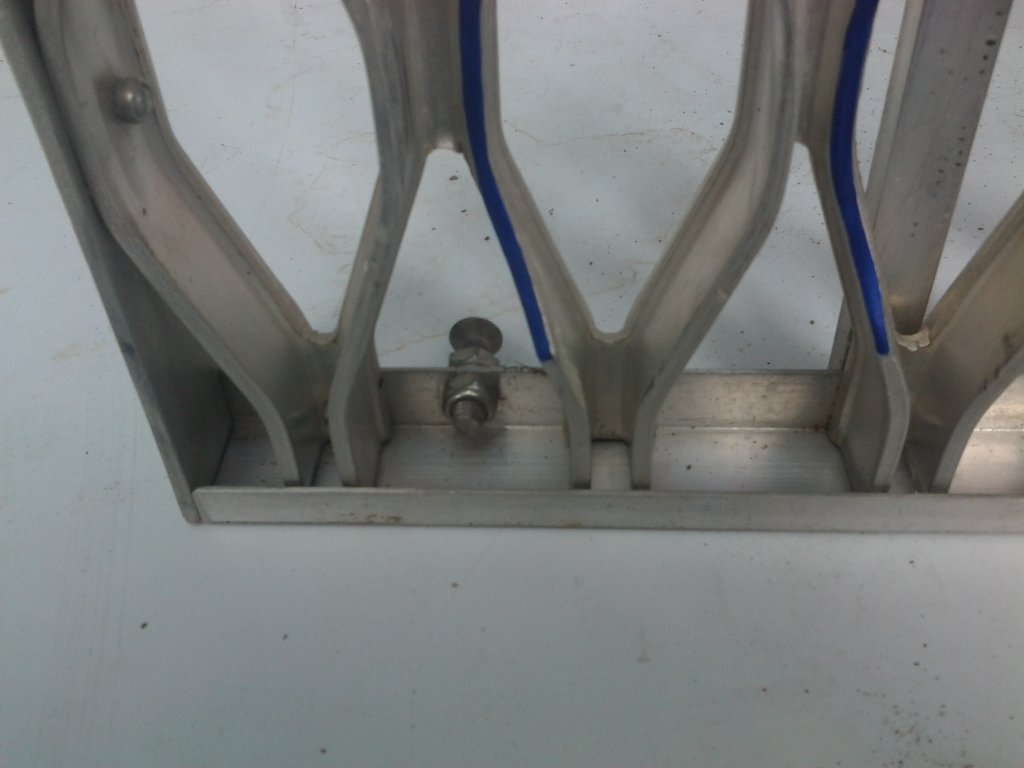

a much larger air gap between the base of your banker and the bottom edge of your mesh is totally the go, But! You must run an under flow restrictor 3/4 the way up the top, reducing it back to approximately 3-4mm.

I use a piece of angle inverted.

Believe it or not... my air gap is almost 18mm! Not including the restrictor.

If you run this stuff first, you will be cutting down your banker in length in no time!

Honestly ignore all the slanted mesh, moss, this and that. And run 300mm of this stuff... without matting! And you will be surprised at how simple and easy this stuff works.

The cook and I went halves in some dream vortex mat.

I do like it ! I've 18 inches of it after the mesh... not a fly poop of gold in it.

but im sure as the mat will run perfectly in a river sluice alone.

It is nice to have the mat as a back up principal following the mesh.

So easy to clean up with little cons.

im more than happy to keep using it.

dont under estimate buying the 6" stuff. It dose seem to like a good flow of water, this I believe is a better way than too add more decline.

What you are trying to create is a whirlpool, this can be undoone by too much angle. ( my interpretation anyhow)

Your want the water flow and turbulence to make it work more so than just a fast drop.

who cares if you think you have too much black in your cells! It's obviously working and any gold will beat that stuff too the bottom anyhow.

I think if your lower point of the "J" isn't self cleaning within reason. Then add more water before dropping any angle ratio.

Dont expect to just see gold in the cells! If your seeing a lot of black... your on the right track. :Y:

But with modifications.

Firstly I use the 20mm cat walk mesh as opposed to the 12mm.

Scalloping the high side of the webs really helps a good turbulence in the baffle principal, takes a bit of time to do but very needed.

a much larger air gap between the base of your banker and the bottom edge of your mesh is totally the go, But! You must run an under flow restrictor 3/4 the way up the top, reducing it back to approximately 3-4mm.

I use a piece of angle inverted.

Believe it or not... my air gap is almost 18mm! Not including the restrictor.

If you run this stuff first, you will be cutting down your banker in length in no time!

Honestly ignore all the slanted mesh, moss, this and that. And run 300mm of this stuff... without matting! And you will be surprised at how simple and easy this stuff works.

The cook and I went halves in some dream vortex mat.

I do like it ! I've 18 inches of it after the mesh... not a fly poop of gold in it.

but im sure as the mat will run perfectly in a river sluice alone.

It is nice to have the mat as a back up principal following the mesh.

So easy to clean up with little cons.

im more than happy to keep using it.

dont under estimate buying the 6" stuff. It dose seem to like a good flow of water, this I believe is a better way than too add more decline.

What you are trying to create is a whirlpool, this can be undoone by too much angle. ( my interpretation anyhow)

Your want the water flow and turbulence to make it work more so than just a fast drop.

who cares if you think you have too much black in your cells! It's obviously working and any gold will beat that stuff too the bottom anyhow.

I think if your lower point of the "J" isn't self cleaning within reason. Then add more water before dropping any angle ratio.

Dont expect to just see gold in the cells! If your seeing a lot of black... your on the right track. :Y: