Thought I might put up a "hot tip" post for identifing alignment issues having to do with jigs, dops and machine.

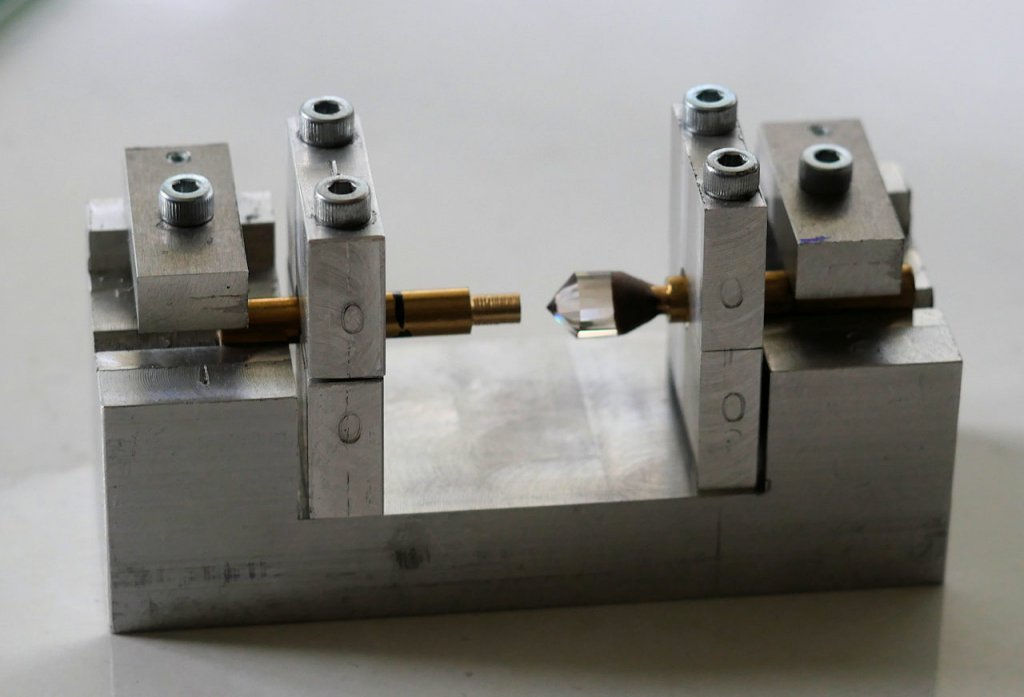

Easiest way is to get your hands on one of these below. Facetron supply them with their machines however I'm sure any good machinist could lathe one up for your needs. This is called a target dop. The center point is the truest centre point and is made specifically to suit each transfer jig. Its really simple to use and has multiple functions.

Use 1. Checking transfer jig accuracy

Place the dop in the base of the jig and a 3mm dop in the top and lower it onto the target. If the 3mm dop is off its either bent or the jig is stuffed. One thing to watch out for is keyed dops. Facetron keyed dops have to go into the jig with the same orientation on both sides otherwise it will be way out.

Use 2. Checking a bent dop

There are 2 kinds of stair-stepping girdles. Before transfer and after transfer. If you are dealing with stair stepping girdles BEFORE transfer you can bet your ass something is very wrong. It is sometimes possible that an issue like a bent or worn mast, misaligned platen or rubbish laps can cause the problem but if your machine is well looked after and maintained, these kinds of problems can be ruled out almost immediatley.

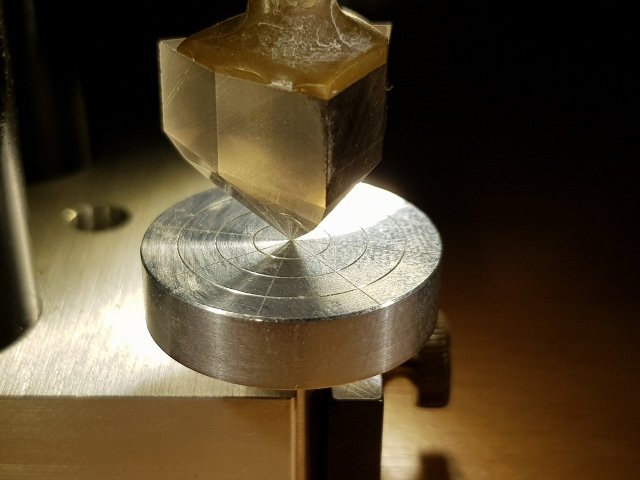

Diagnosing a bent dop will require identifying 2 symptoms. First symptom, as described, is stairstepping girdles before transfer. Even if it is only very slight. Second, you will need to cut your stone to a point as accurately as you can either using the dial indicator/digital indicators or to sound. Then you will need to put the stone into the jig and test with the target dop. If its off centre you most likely have a bent dop.

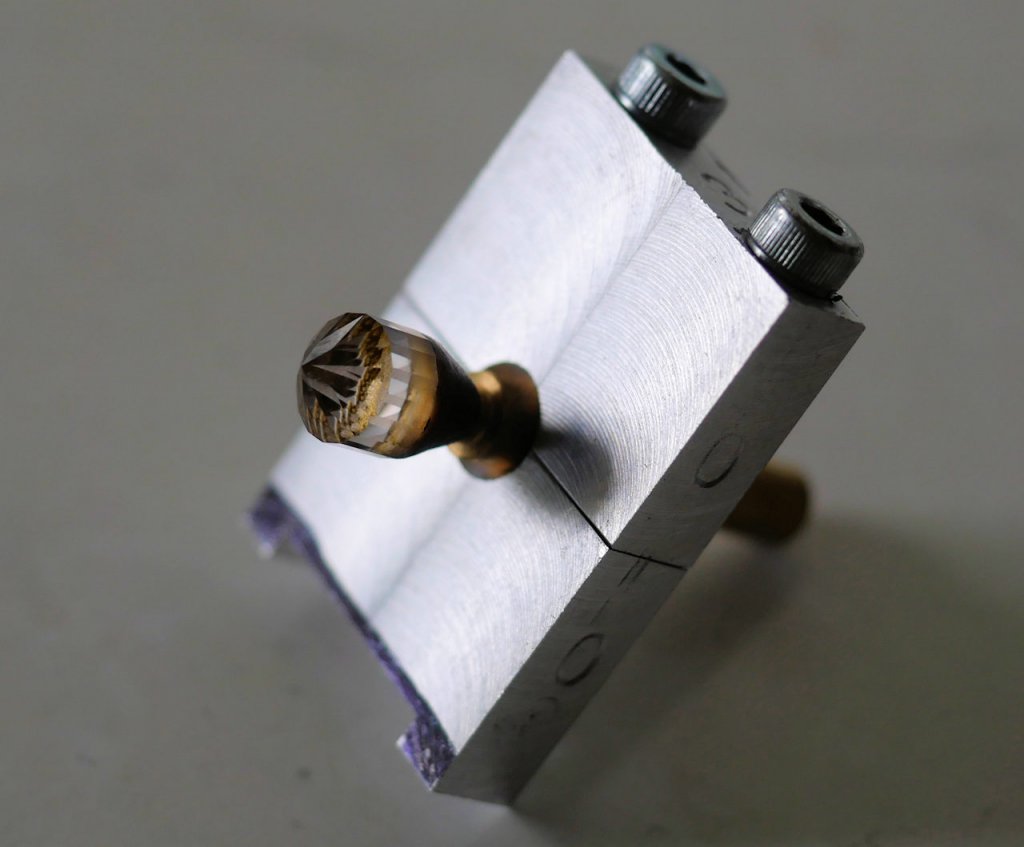

Image below is about as far as I got with the smoky before I realised something was wrong. As you can see the transfer jig and dop a perfectly ok. The next step from here is to start working my way back up the machine to diagnose what issue could possibly be causing the stair stepping girdles. I have sent the head back to the States to be professionally calibrated and have the quill replaced. I will also be picking up a new mast just to be sure everything is spot on. Probably overkill but I don't want to be down for any longer than I have to be.

Notes on stair stepping girdles:

As discussed above, stair stepping Before transfer is a huge red flag. This means something is wrong with the equipment or the bond (wax, glue etc) is shifting as you are cutting.

Stair stepping AFTER transfer is a whole diffrent kettle of fish. There are two very common causes to this frustrating issue. Either it was a bad transfer, or you forgot to zero the cheater before you began cutting the stone. Bad transfers can be difficult to correct if the stone has shifted along multiple axies. i.e bad transfer caused stone to rotate to the left and dipped slightly forward. Nightmare to correct

Forgetting to zero the cheater is not a big issue. Just adjust where nessecary and test. I like to leave a bit of meat on the crown as I cut the first sequences in. That way I can check for stair stepping before setting the girdle thickness. It pays to be extra careful when cutting high value material especially when dopping with wax.

Best way to zero the cheater is as follows (works best for keyed dops):

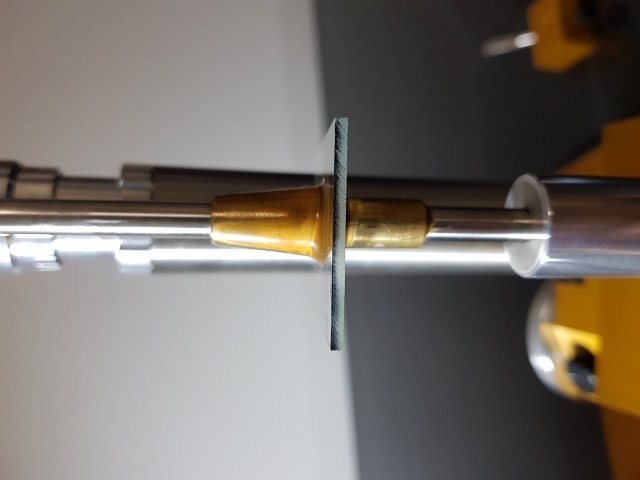

- Make one of these below. Its a piece of thin glass approx.. 1 inch long, dopped perfectly between 2 dops. [/*]

- Grind it to a flat edge. [/*]

- Colour the flat edge with a permanent marker[/*]

- Switch the tool over to the opposite side and LIGHTLY touch it to the lap at 90 degrees[/*]

- If the marker is ground off one side but not the other the cheater is out and you need to adjust accordingly. The aim is to have the entire length of the glass touching the lap instantly.[/*]

The longer the glass edge the finer the zeroing. However, the longer the edge the more difficult and time consuming it is to zero. 1 inch works a treat for me. A perfectly zeroed cheater should look like this:

If you do encounter a difficult problem then the best way to solve it is almost always take a break, have a coffee and come back to it. Its amazing how many variables ones subconscious can crunch in the back ground.

:Y:

:Y: