- Joined

- Jan 2, 2017

- Messages

- 2,328

- Reaction score

- 3,015

I have tried several fitting applications that I was never 100% happy with.

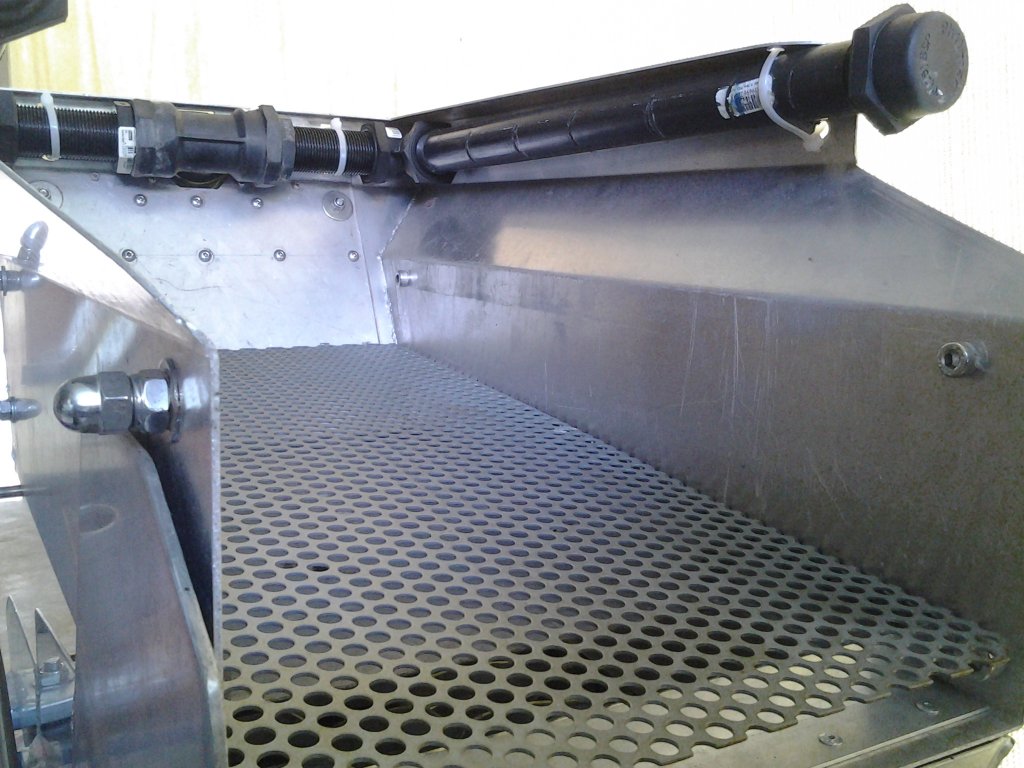

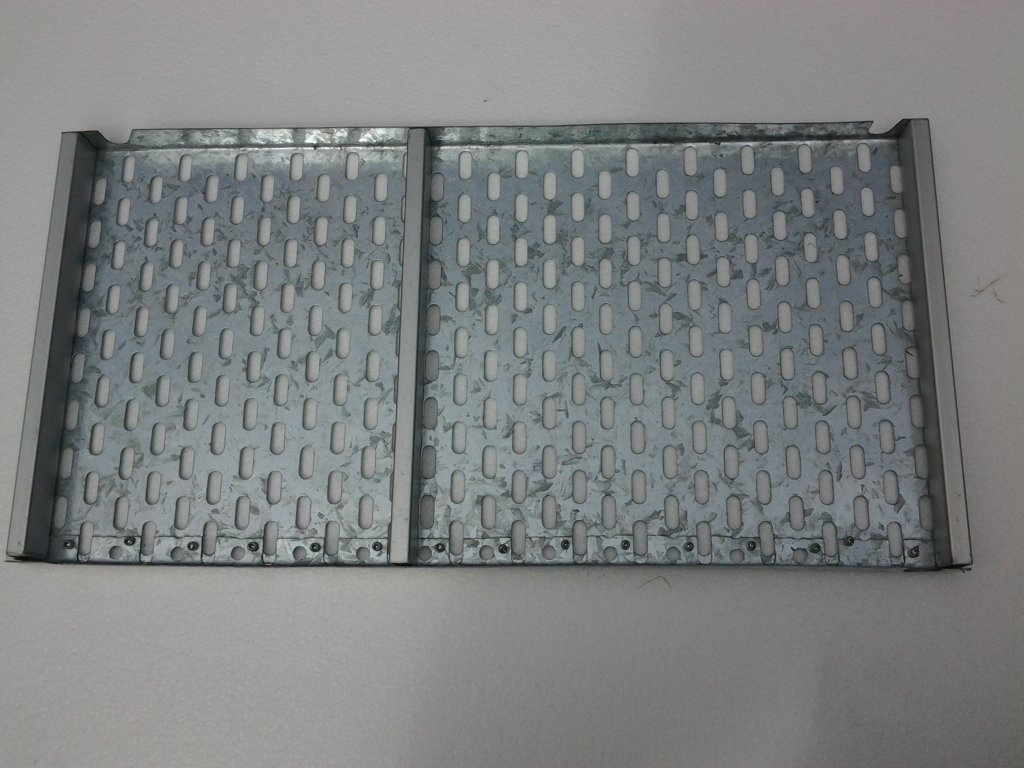

So here's a few tips to beefing, cutting the tray down to suit hopper width, and easy mounting, using 10mm stainless cap screws as locator ludgs. Note, dont use washers on the inside of the hopper behind cap. You will note I do run two trays/ classifiers. The second lower is 8mm punch, and is is not parraral to the base. It is higher at the back, tapered down. Allowing for more fall and hand access

this has it's advantages and some disadvantages, but more advantages.

It dose also allow more break down time for dirt and clay, as it gets a good extra showering, exra classification is good. But shea oak roots will accumulate on punch plate easily. But it is easily wiped off.

Rhs pop riveted at both ends and one across the main drop zone helps stop the bowing, keeping the fittment shape intact.

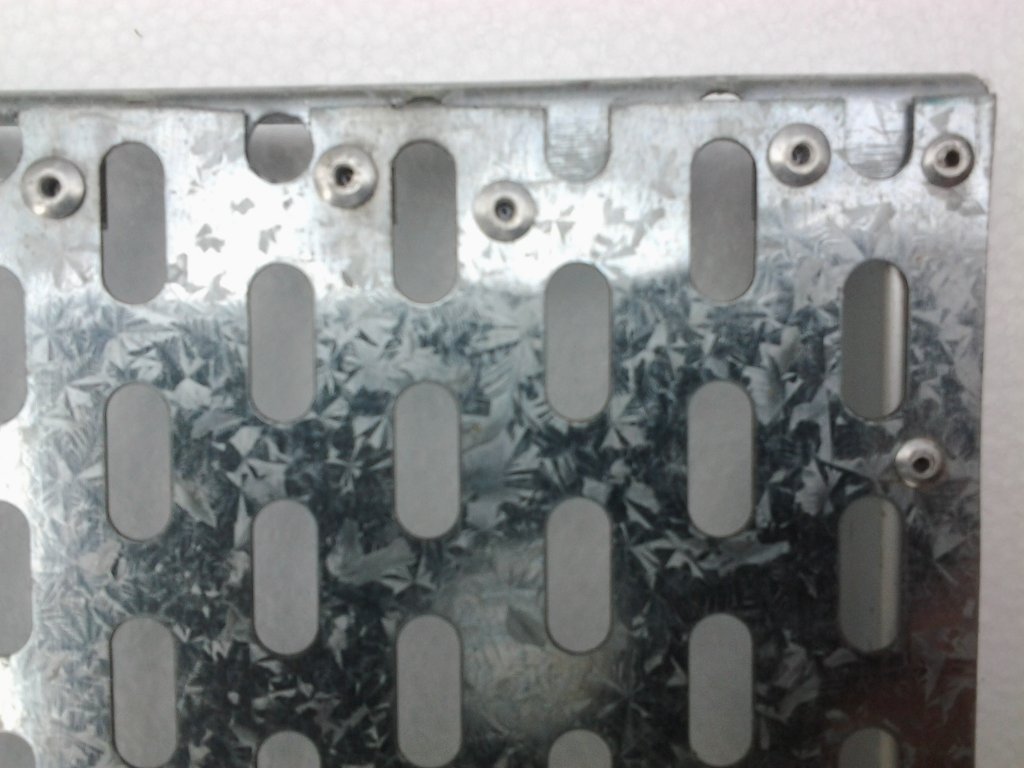

Once you have chosen the 10mm holes for the locating stud lugs, tin snip the lower end of cable tray hole up the upper side of holes, then a verticle cut up to the 3 oclock postion on tray. This makes for easy placement, file of neaty.

.