This is how I make mine

Get hold of the following:

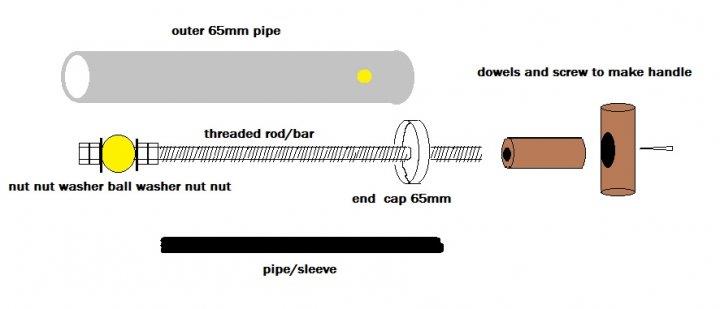

1 metre length of 65 mm waste pipe

1 meter length of 12mm galvanized threaded rod/bar plus 4 nuts and extra large washers (3-5cm) to fit

a standard sized tennis ball

some 13mm tubing/conduit/plastic pipe

a 65mm push on end cap

some pieces of cylindrical wood 25mm diameter about 100 mm in length (cut from a dowel or broom shaft etc)

Tools

Hacksaw

Wood saw

drill

25mm flat wood bit

9 or 10mm wood/metal bit

13/14mm wood/metal bit

araldite or other epoxy resin

method

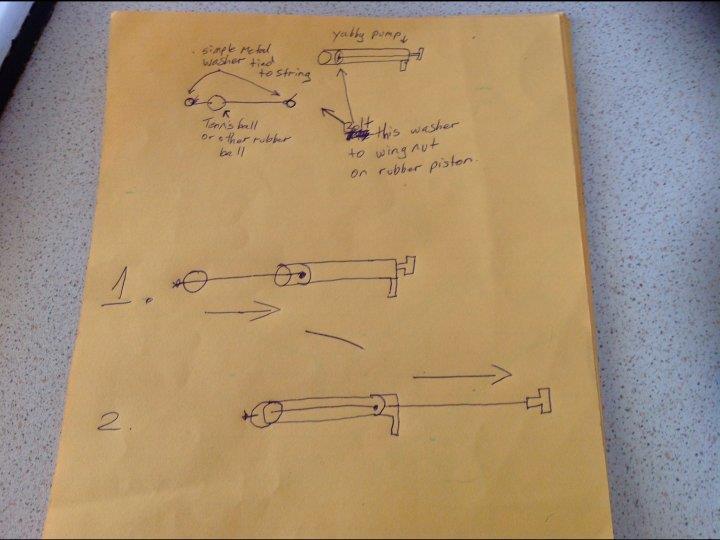

drill the tennis ball all the way through the middle and out the other side.

put the bar through the ball with a washer and 2 nuts either side to sandwich the ball.

the bottom (outer) nut wants to be either flush with the bottom of the rod or on the rod with a turn over.

push the tube/pipe/conduit over the threads of the rod (long end) leaving approx 40mm of threads exposed.

drill a 13/14mm hole through the centre of the end cap and put this over the rod.

The whole assembly can now be put into the 65mm pipe to check for snugness (you may need to tighten those nuts to compress the tennis ball)

take one of the 10cm dowels and drill a hole in the centre of one end to a depth of 4cm. This will then screw onto the top of the threaded rod to make part of the handle. secure with resin.

take the other dowel and find the centre point of its length. at this point drill vertically down with the flat bit until the point just protrudes through the other side. This will now make the other part of the 'T' handle.

secure with a woodscrew and resin.

last thing, drill a 10mm hole in the 65mm pipe about 3cm below where the end cap fits on as a vent for the air to escape when you pull the plunger.