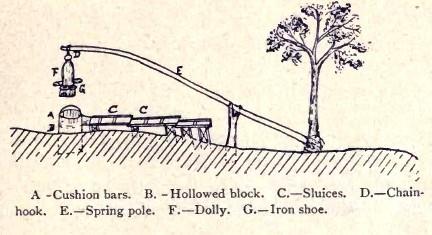

Has anyone seen a spring dolly in action or has seen some old pictures of one? From reading it sounds like a good device for one man operation. Maybe with modern materials i may be able to make it better?

I have a few stones to crush and wont something faster than a hand dolly, but keeping away from motorized equipment.

I have a few stones to crush and wont something faster than a hand dolly, but keeping away from motorized equipment.