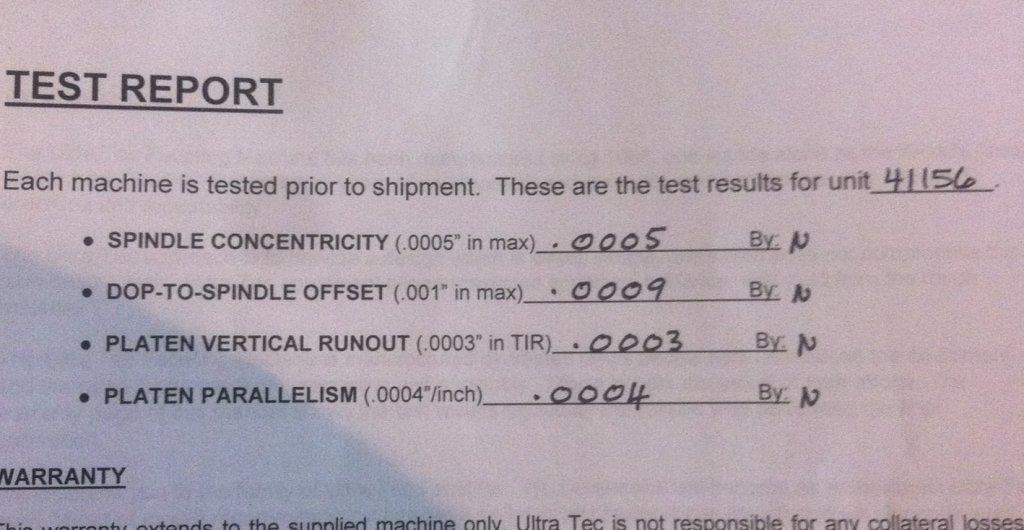

Theres no downside for faceting, digital is the way to go. I had an incident a few years back where I had to redo a lap three times, each time I got what I called a perfect finish, and each time returned due to runout. I lost Time and Postage only to find out the digital faceting machine had a spindle issue. The lap was perfect. There is a point where a facetor has to learn to adapt to these sort of incidents as these days diagrams are to three decimal places generated by computer. most people with an older machine wont ever be able to achieve these parameters. Another was a comp cutter who showed me his stone saying that they were cut to computer angles and dead perfect asked me to tune his machine head which turned out to be out by 1.5 degrees. So all his work was out by that for at least a year or more. My lathe cost me $10,500

dollars and was purchased new and if you took a lap just machined on my other lathe and then machined it on the new lathe you can see the runout. I cant afford the $100,000 german made super lathe just to do a dozen redos at $15 ea. Im still having issues with my sintered systems that's why they aren't yet available on the market.

Runout on a sintered laps a bitch to fix, guess I need better machinery for that. Time and money.