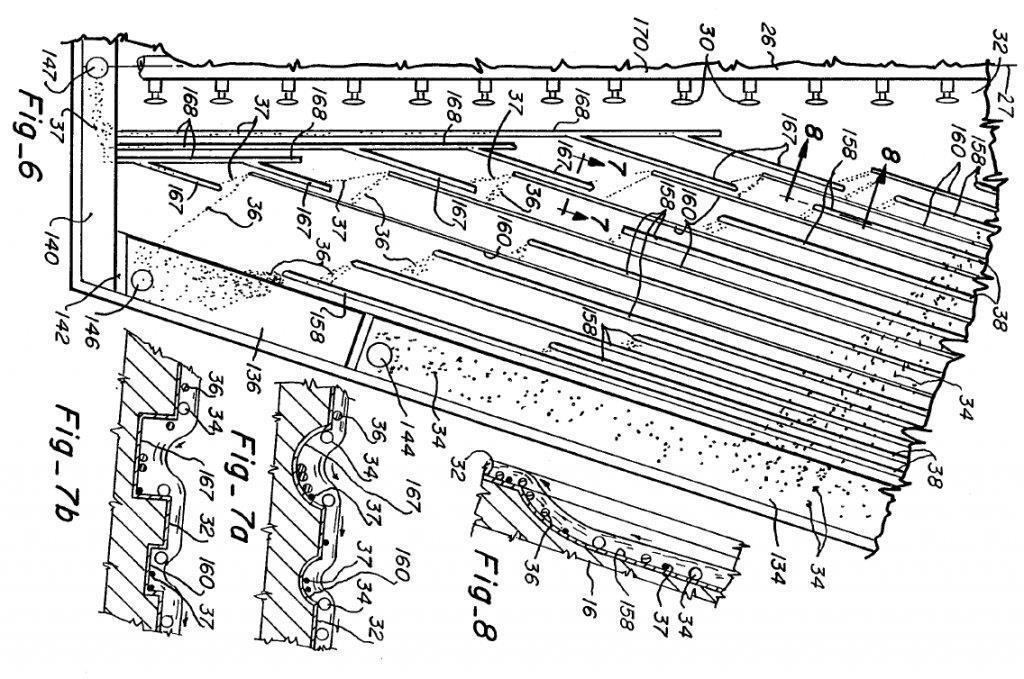

As I have a lot of fines to process,I needed a shaker table so I have been building one,over the last 6 months off and on,so here is the final product.

There was a lot of trial and error along the way to make it work,making it run smooth,and the table top was a bit of challenge with grooves and having them right depth and also smooth.

Regards The Digger

There was a lot of trial and error along the way to make it work,making it run smooth,and the table top was a bit of challenge with grooves and having them right depth and also smooth.

Regards The Digger