ArmstrongIndustries

Armstrong Industries

- Joined

- Oct 26, 2013

- Messages

- 79

- Reaction score

- 87

Yes I'll run a few tests next week. See how it goes. Should be easy to setup.

rc62burke said:Hey Hare Twigga

Mate just going by the vid, from what I see I think you need a "Sluice" with a bit more aggressive "Riffle" or a catch tray sytem at the head of your sluice, as you are getting gold all the way down your sluice, most likely overloaded, not a criticism, just what I see, plenty of gold though.

cheers

Lee

ArmstrongIndustries said:We have always used the rock breaker into dryblower then put the concentrate into a water wheel. Have found we needed to put back through water wheel about 3 times to make sure we got all the gold out.

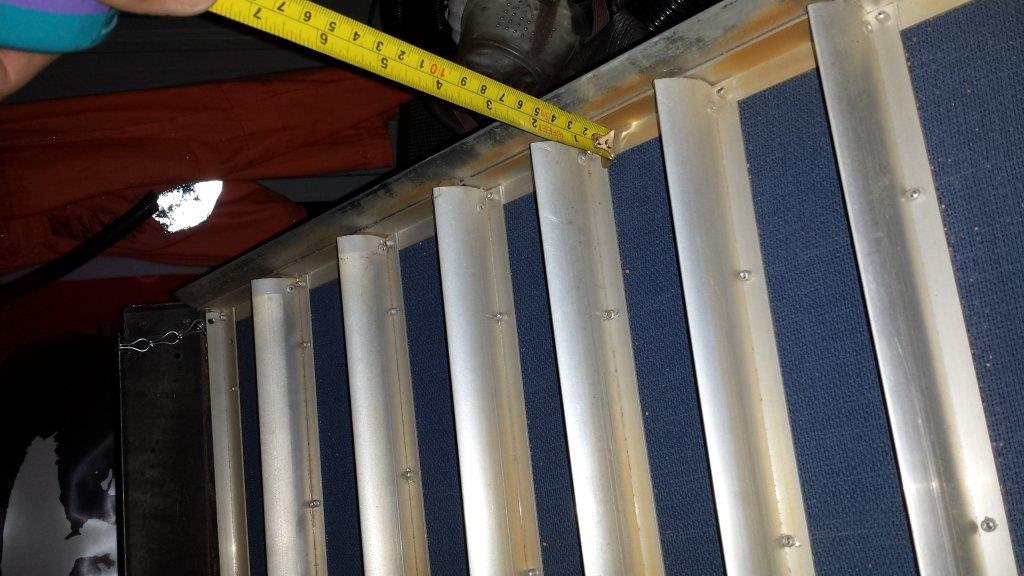

I'm almost ready to leave the water wheel at the back of the shed to collect dust now as I have a shaker table now.

ArmstrongIndustries said:We have always used the rock breaker into dryblower then put the concentrate into a water wheel. Have found we needed to put back through water wheel about 3 times to make sure we got all the gold out.

I'm almost ready to leave the water wheel at the back of the shed to collect dust now as I have a shaker table now.

thedigger said:I found that when the material is very fine the dryblower looses a lot a lot of fine gold

The digger

Enter your email address to join: