- Joined

- Apr 22, 2013

- Messages

- 174

- Reaction score

- 164

Cristinite is a kind of glass (artificial), and like glass, I guess it scratches easily, a bit like TV glass.

SneakyCuttlefish said:Just finished this one. It looks good but the finished product isn't what I had hoped for. This is a modified el dorado brilliant cut. 15mm topaz. Ill add the carat weight this afternoon.

The rough had a thick but very light blue zone running at 90 degrees to the table. Unfortunately I failed to spot a flaw in the crown that ended up penetrating the table so had to remove 16 facets from the top to bring the table height down enough take most of the flaw out. A small amount can still be seen at the 7 o'clock position in the photo. A very large table coupled with a few angle changes resulted in a lot of the color bleeding out of the crown sides instead of being reflected back into the stone and out through the table. As can be seen at the 2 o'clock position.

Anyway, this was a very difficult cut for me as I haven't had to deviate so far from the original design before. I also found that when using an old machine and old laps even the slightest bit of wear and tear can effect the accuracy hugely. It would appear over time the play in the joints and locks for the head has made it a bit more flexible then it should be so constant eyeballing is required to get even the most basic cuts right. Another issue I encountered is rust specks on the 3000 pre-polish lap that reduce my usable space to a narrow band. This issue resulted in a 4 hour polish, just for the table alone. This will probably be my last stone for a while as I don't want to invest the time and my hard won material on this particular machine.

Facetron or Ultra tec.... hmm??

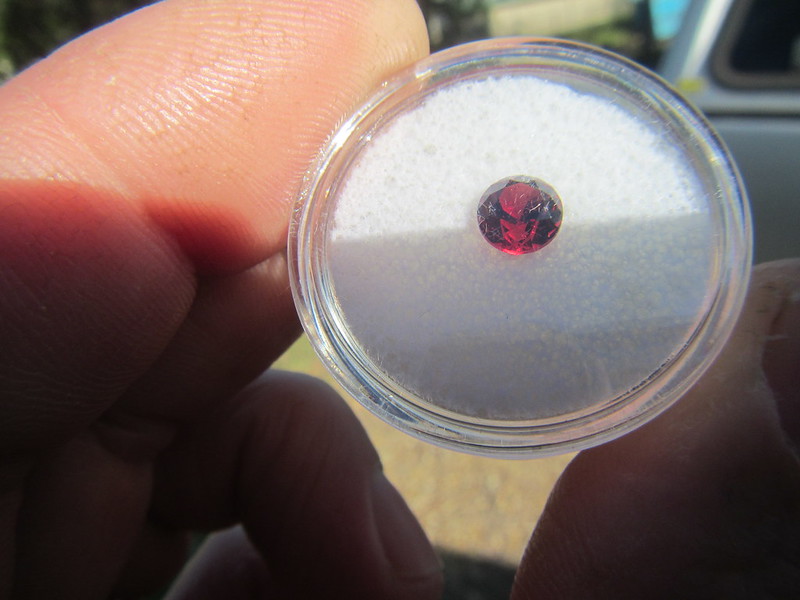

https://www.prospectingaustralia.com/forum/img/member-images/3340/1431830202_img_1790_640x480.jpg

I ve been looking for that. Design . Have you got. A pic or a link for me?Lefty said:Hartz range material X, cutting it in the "Lighthouse" design.

https://farm1.staticflickr.com/408/18446173385_4d6e06da58_c.jpg

Still not certain as to what it is, picked it up out there about 5 years ago. Looks like clear quartz but has some things about it that have always made me wonder. It displays a perfect-looking cleavage plane which quartz does not have. Am sending a bit of to a gemmologist, hopefully he will solve a five year old mystery.

I suspect it might be petalite but I'll have to wait to find out.

Finished the pavillion last night. Tried to polish on #60 000 diamond - didn't do a very satisfactory job. Moved to cerium oxide and it quickly took on a nice, bright polish. One of the huge facets - lighthouse has only four big pavillion facets - polished with some difficulty, though it did eventually take on an acceptable finish. Looking through the loupes, there are minute inclusions just under the surface of that facet, like tiny needles all running the same direction. They actually appear to go right through the stone but are invisible through the other three facets. I haven't seen anything that looks quite like this in any of the quartz I've faceted so far.

The stuff looks like it would make a nice, bright gem. Will see how it turns out when I hopefully finish it today since I ain't going in to work.

Sodabowski said:Any occurences of kunzite in the region? This could be one...

Enter your email address to join: