Teemore

One foot out the door

Might sound silly, and it's just to make sure I don't ruin my equipment but,

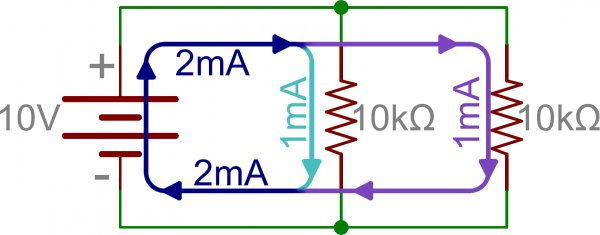

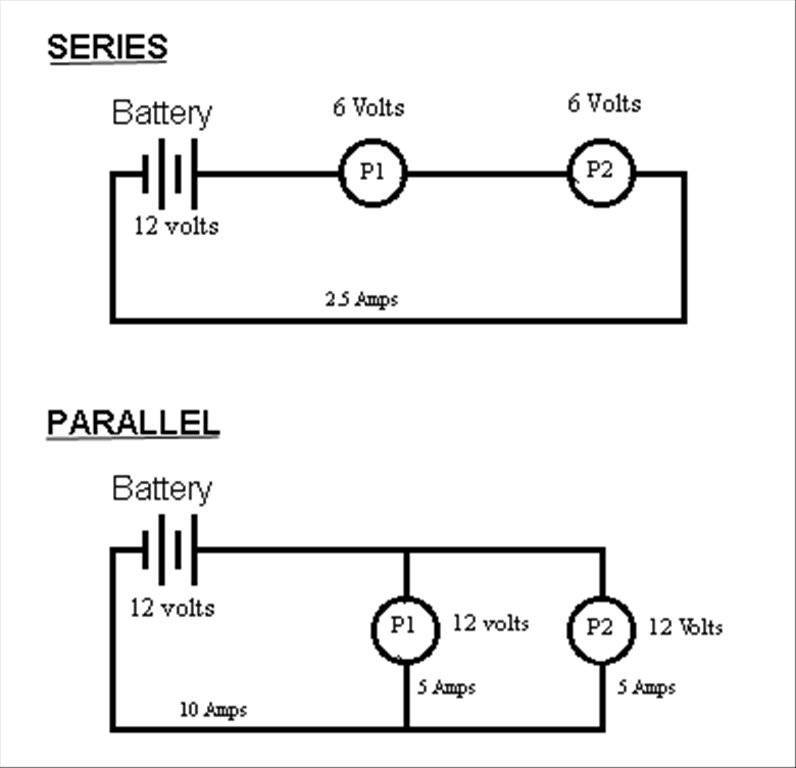

Is there any reason, apart from a quicker flat battery, why you can't hook up 2 12v bilge pumps to a single battery?

Looking to run extra water volume or a different water pressures to assist in breaking up soil through the sluice.

Do have 2 batteries but 1's ex auto so a bit heavy.

Cheers T.

Oh, and just cleaning up my gear .... how have I ended up with 7 pans, bastards must breed.

Is there any reason, apart from a quicker flat battery, why you can't hook up 2 12v bilge pumps to a single battery?

Looking to run extra water volume or a different water pressures to assist in breaking up soil through the sluice.

Do have 2 batteries but 1's ex auto so a bit heavy.

Cheers T.

Oh, and just cleaning up my gear .... how have I ended up with 7 pans, bastards must breed.