- Joined

- Oct 23, 2019

- Messages

- 134

- Reaction score

- 196

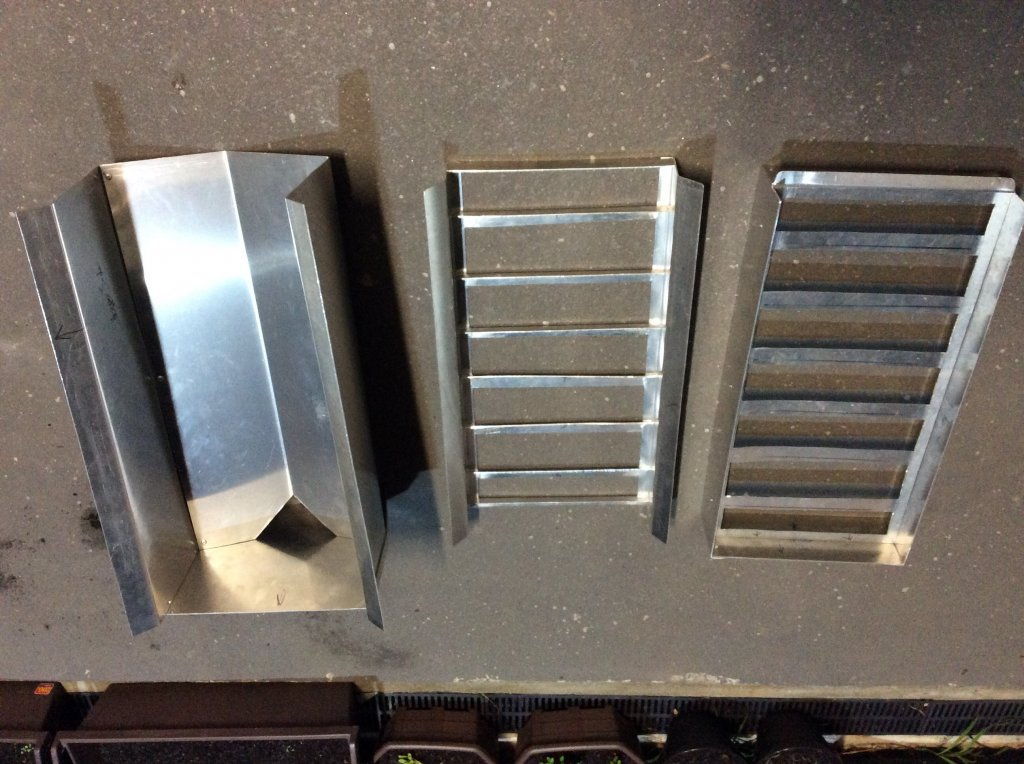

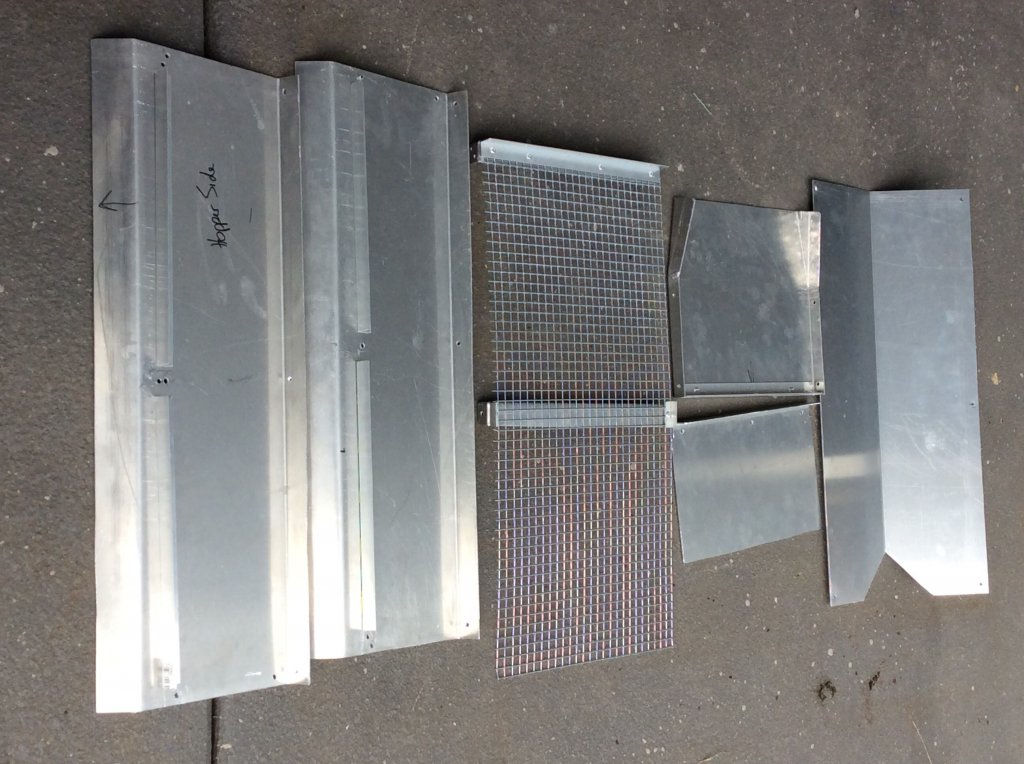

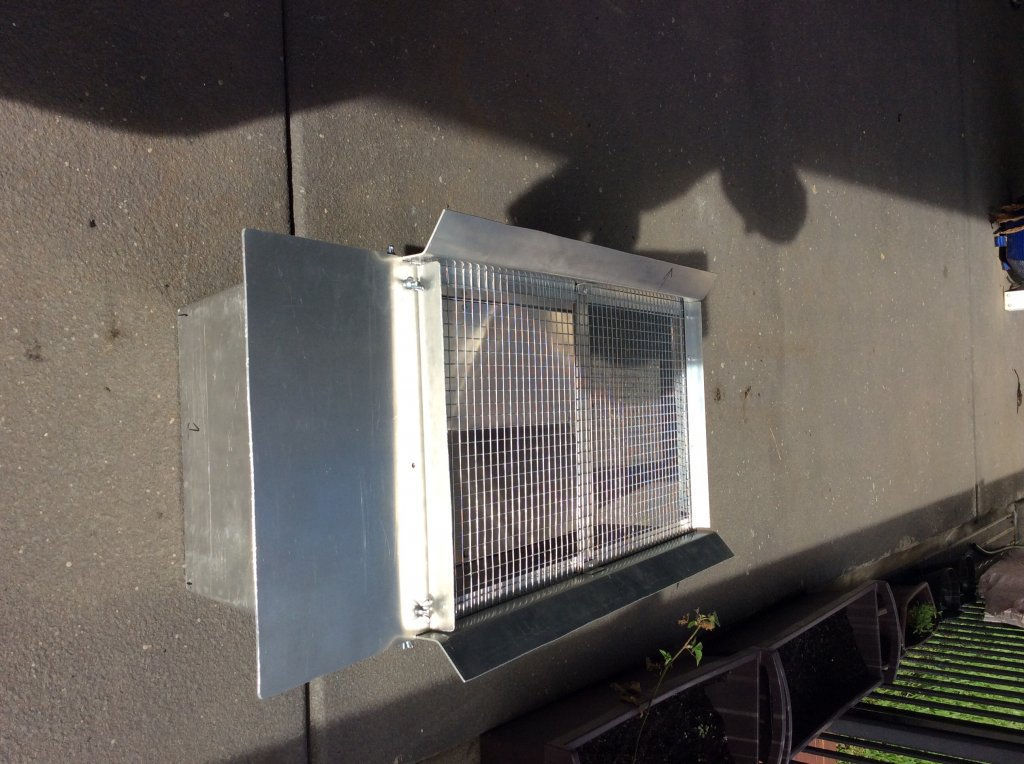

Started building a bellows Dry washer out of 2mm Aluminum sheet

Making it up as I go along

Haven't done anything in Aluminum before. Using basic tools. 690mm long x 340mm wide

Will add photos as I create each part

Build for my trip to Tibooburra

Cheers

Making it up as I go along

Haven't done anything in Aluminum before. Using basic tools. 690mm long x 340mm wide

Will add photos as I create each part

Build for my trip to Tibooburra

Cheers