- Joined

- Nov 7, 2019

- Messages

- 71

- Reaction score

- 124

Gday all...

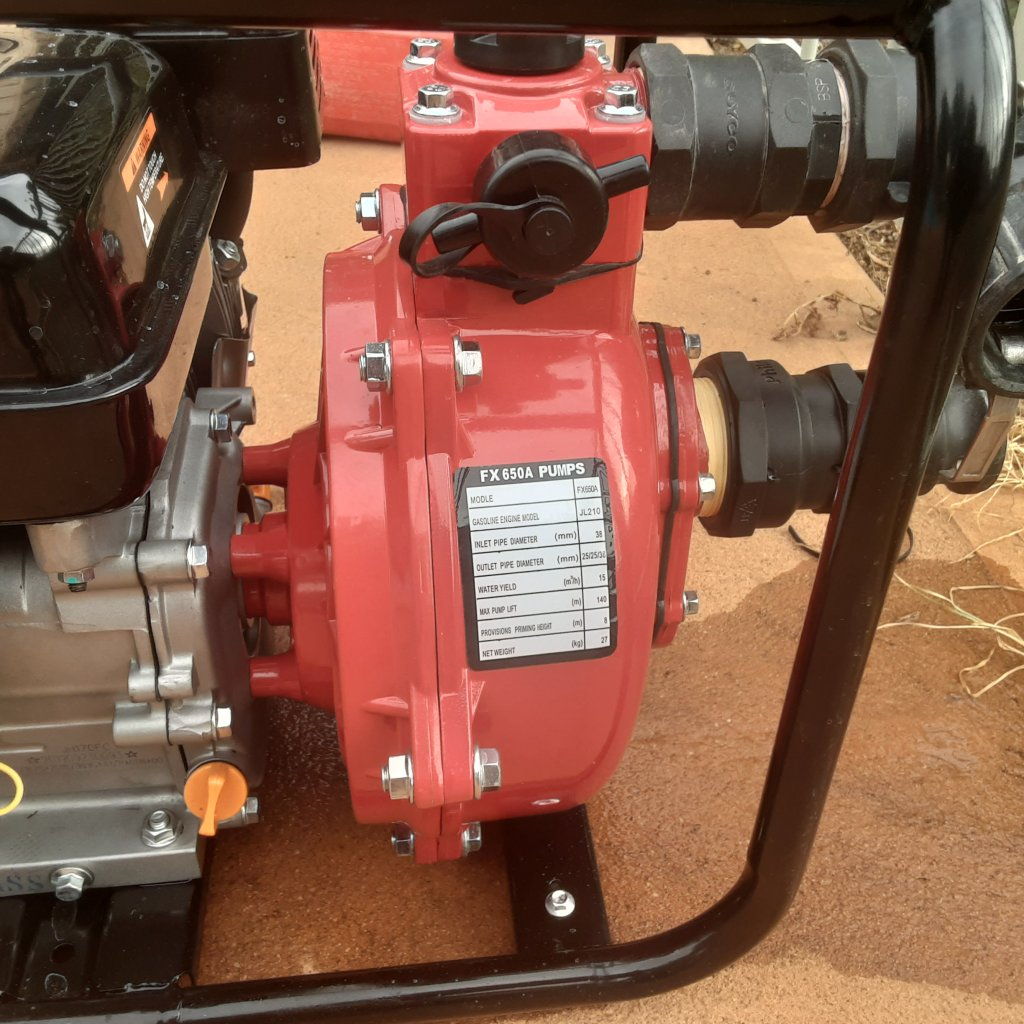

im considering purchasing a Giants Water Transfer Pump to use with a Highbanker Sluice.

Its a 2-inch High Flow Petrol Water Tank Irrigation Pump 4-stroke 210cc 30,000L/hour.

(hoses not included)

Now being a total noob, would this be the right size pump to use with an 8in Highbanker w/ dream mat? or is this size pump overkill?

Regarding hoses - im looking at flat 2in hose (blue) but it has no connectors attached ....

is it advisable to get the hose WITH connectors already attached? if this be the case id assume local pump/irrigation shop could assist there.....

thanks in advance for any help ickshovel: :koala:

ickshovel: :koala:

im considering purchasing a Giants Water Transfer Pump to use with a Highbanker Sluice.

Its a 2-inch High Flow Petrol Water Tank Irrigation Pump 4-stroke 210cc 30,000L/hour.

(hoses not included)

Now being a total noob, would this be the right size pump to use with an 8in Highbanker w/ dream mat? or is this size pump overkill?

Regarding hoses - im looking at flat 2in hose (blue) but it has no connectors attached ....

is it advisable to get the hose WITH connectors already attached? if this be the case id assume local pump/irrigation shop could assist there.....

thanks in advance for any help