You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

some stones i have cut

- Thread starter indi

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- May 5, 2017

- Messages

- 3,839

- Reaction score

- 7,733

The last one is gorgeous...

Nice work indi ...

Goody

Nice work indi ...

Goody

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

nice cutting and polishing, have just started recently myself 100s of youtube watched, what set up are you using the diamond wheels or the flat lap ones, also do you use cerium for final polish, sorry for the questions mate. i have 600, 1200, 3000 flat laps, 1000 wet or dry sticky side wheel,and a cloth compound wheel. would love the diamond wheels but too expensive to justify, maybe if id cut and polish 20hrs a week i would consider then. any info would be much appreciated . gg. :Y:

That 2nd last one is just WOW looks like it was painted. Tree fern you say , absolutely spectacular. Cheers.

I mostly cut opal so i spoiled myself and got a machine with 6 wheels i mostly use 220 600 1200 and 3000 and a felt wheel with cerium oxide, but depending on the stones your cutting if its agates etc you probably 100 220 and up. i hope that helps

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

thanks indi thats a great help thanks, pretty much the same grits i have been using, if all goes well santa may bring me a 6 wheel machine gotta be extra good all yearindi said:I mostly cut opal so i spoiled myself and got a machine with 6 wheels i mostly use 220 600 1200 and 3000 and a felt wheel with cerium oxide, but depending on the stones your cutting if its agates etc you probably 100 220 and up. i hope that helps

grumpygold said:nice cutting and polishing, have just started recently myself 100s of youtube watched, what set up are you using the diamond wheels or the flat lap ones, also do you use cerium for final polish, sorry for the questions mate. i have 600, 1200, 3000 flat laps, 1000 wet or dry sticky side wheel,and a cloth compound wheel. would love the diamond wheels but too expensive to justify, maybe if id cut and polish 20hrs a week i would consider then. any info would be much appreciated . gg. :Y:

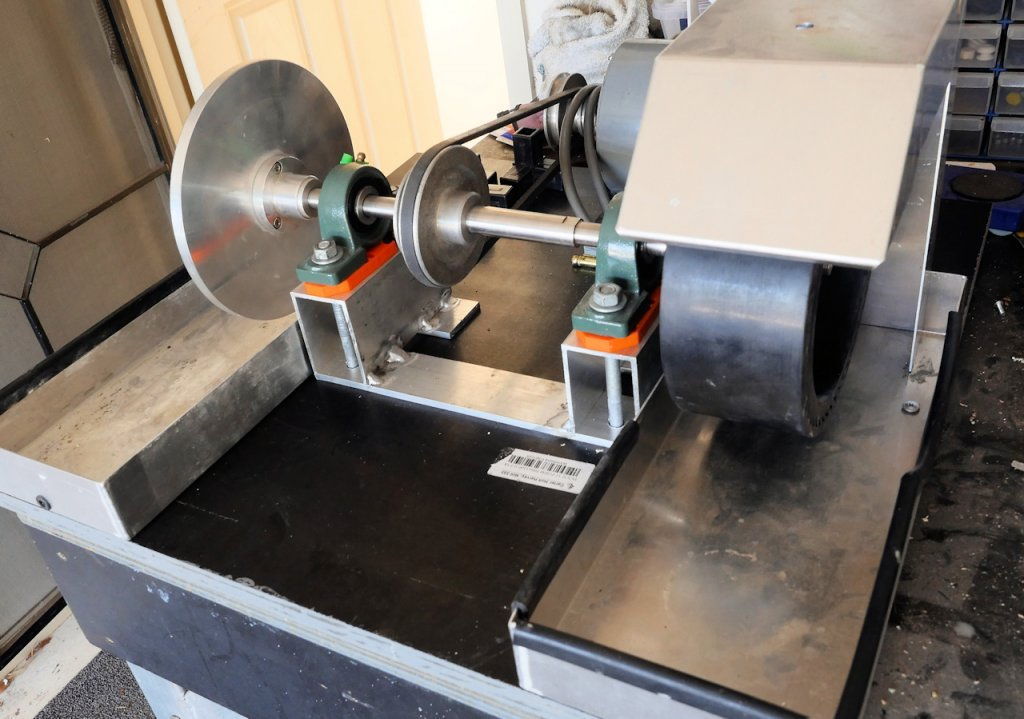

Just finishing a rig for stone, using an 8" flat one end and an 8" expanding drum the other, we can then buy diamond laps and belts so works out a lot cheaper than the big drum machines and much more flexible.

We'll set up a bunch of stones on dowel dops, work them on one grit, then change the laps and work on through. Also gives a lot more flexibility with the grits we use.

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

hi i would be interested in seeing a picture of yor finished machine if possible, thanks for the advice as well, all and any appreciated cheers.Dihusky said:grumpygold said:nice cutting and polishing, have just started recently myself 100s of youtube watched, what set up are you using the diamond wheels or the flat lap ones, also do you use cerium for final polish, sorry for the questions mate. i have 600, 1200, 3000 flat laps, 1000 wet or dry sticky side wheel,and a cloth compound wheel. would love the diamond wheels but too expensive to justify, maybe if id cut and polish 20hrs a week i would consider then. any info would be much appreciated . gg. :Y:

Just finishing a rig for stone, using an 8" flat one end and an 8" expanding drum the other, we can then buy diamond laps and belts so works out a lot cheaper than the big drum machines and much more flexible.

We'll set up a bunch of stones on dowel dops, work them on one grit, then change the laps and work on through. Also gives a lot more flexibility with the grits we use.

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

do you mine your opal or do you buy rough parcels, seems a big variation in quality of rough for around same price, depends on the seller i guess :Y:indi said:good luck it soon pays for itself and love that specimen on your avatar pic

grumpygold said:hi i would be interested in seeing a picture of yor finished machine if possible, thanks for the advice as well, all and any appreciated cheers.:Y:

Pretty simple really, bunch of off-cuts around the place, some thin Ali from Bunnings, just had a mate turn up the shaft to my spec, pillow blocks from the local bearing shop. Going to make the guard from the 25mm sq Ali and corners one can buy from Bunnings then cover with what ever I have laying around, bit of thin marine ply or ali sheet off-cuts. May even go flash and get some of the textured Ali Bunnings has.

Motor and pulleys came off my Imahashi when I converted it to a variable speed DC motor.

Got to fold up an arched guard for the flat lap, probably glue it together with Sika, easier than long thin welds.

Probably the biggest expense was getting all the flat laps, felts etc, but picked them up as a special package from a guy who had made a mess of trying to do the same thing. He'd based it on a jewellery polishing motor that spins at around 10k rpm so not a hope in hell of being able to work stone or opal with it. This runs at either 1450 or 350rpm so ideal for cutting and polishing.

Should be getting angry pretty soon with some opal we picked up recently.

And pretty Dirty too.  .. Shame to stain such a nice Example of a Home-made Lapidary Machine with-out the price tag... Nice work Dihusky.. :Y:

.. Shame to stain such a nice Example of a Home-made Lapidary Machine with-out the price tag... Nice work Dihusky.. :Y:

LW....

LW....

Cheers Mate :Y: Still finding it to chuck anything away, old farming blood  Dinah can't wait for me to finish it, be good therapy for her :flowers:

Dinah can't wait for me to finish it, be good therapy for her :flowers:

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

i have came across one supplier so far i have been dealing with from lightning ridge so far so goodindi said:I buy directly off the miners and yes there is a big difference just find someone your happy with and stick with them normally you get rewarded for your loyalty

- Joined

- Oct 31, 2018

- Messages

- 346

- Reaction score

- 210

thats one nice looking well built machine, i looked aroung 2nd hand not much available so ended buying all new laps. i reckon i will give something like this ago, being a panel beater and sheet metal worker , will most likely have the same problem with the shaft. was it pricey to get someone to do the shaft for you, also sika is the bees knees been using it in auto industry over 20 yrs nothing beats it :Y:Dihusky said:grumpygold said:hi i would be interested in seeing a picture of yor finished machine if possible, thanks for the advice as well, all and any appreciated cheers.:Y:

Pretty simple really, bunch of off-cuts around the place, some thin Ali from Bunnings, just had a mate turn up the shaft to my spec, pillow blocks from the local bearing shop. Going to make the guard from the 25mm sq Ali and corners one can buy from Bunnings then cover with what ever I have laying around, bit of thin marine ply or ali sheet off-cuts. May even go flash and get some of the textured Ali Bunnings has.

Motor and pulleys came off my Imahashi when I converted it to a variable speed DC motor.

Got to fold up an arched guard for the flat lap, probably glue it together with Sika, easier than long thin welds.

Probably the biggest expense was getting all the flat laps, felts etc, but picked them up as a special package from a guy who had made a mess of trying to do the same thing. He'd based it on a jewellery polishing motor that spins at around 10k rpm so not a hope in hell of being able to work stone or opal with it. This runs at either 1450 or 350rpm so ideal for cutting and polishing.

https://www.prospectingaustralia.com/forum/img/member-images/10304/1547620173_twin_lap.jpg

Should be getting angry pretty soon with some opal we picked up recently.

I think the spindle cost me around $100 or so, and grumpy if you're a metal worker, this'll be a snack for you. Sika... good, some of the Bostic stuff is awesome!!

Keep coming up with stuff like this, one day I'll get myself a lathe...

Keep coming up with stuff like this, one day I'll get myself a lathe...

Similar threads

- Replies

- 0

- Views

- 117