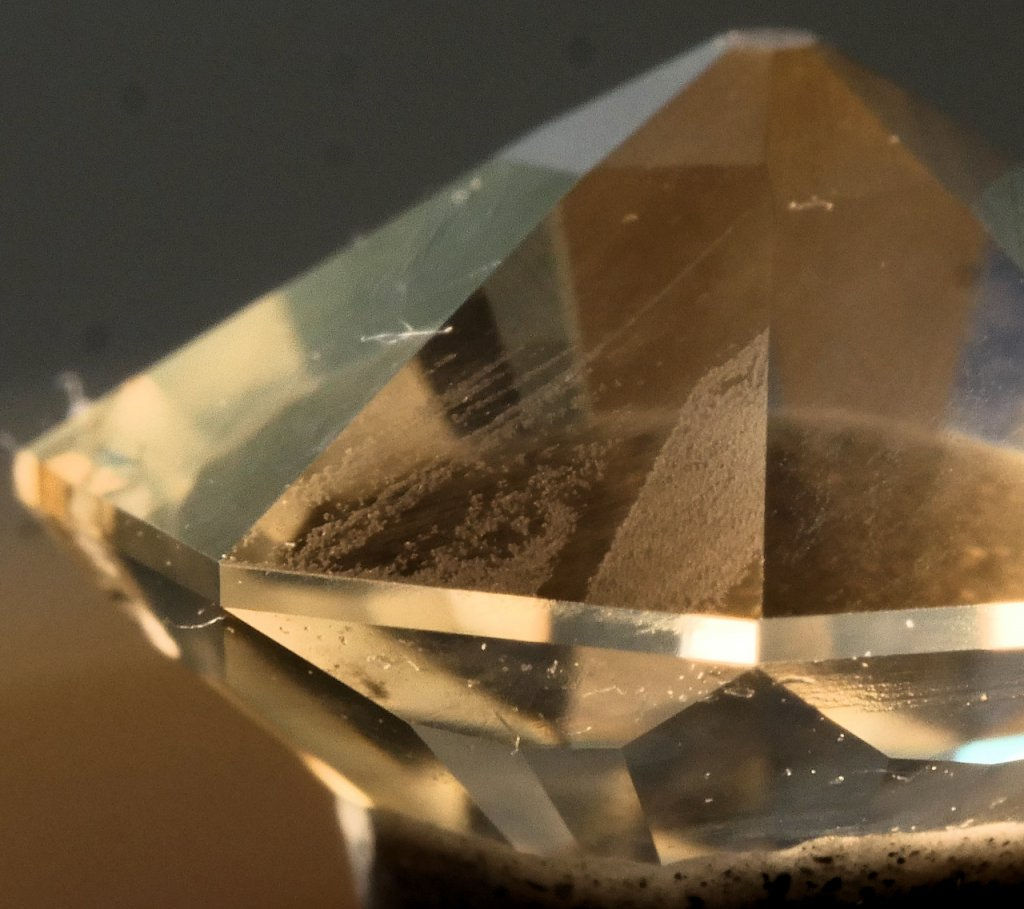

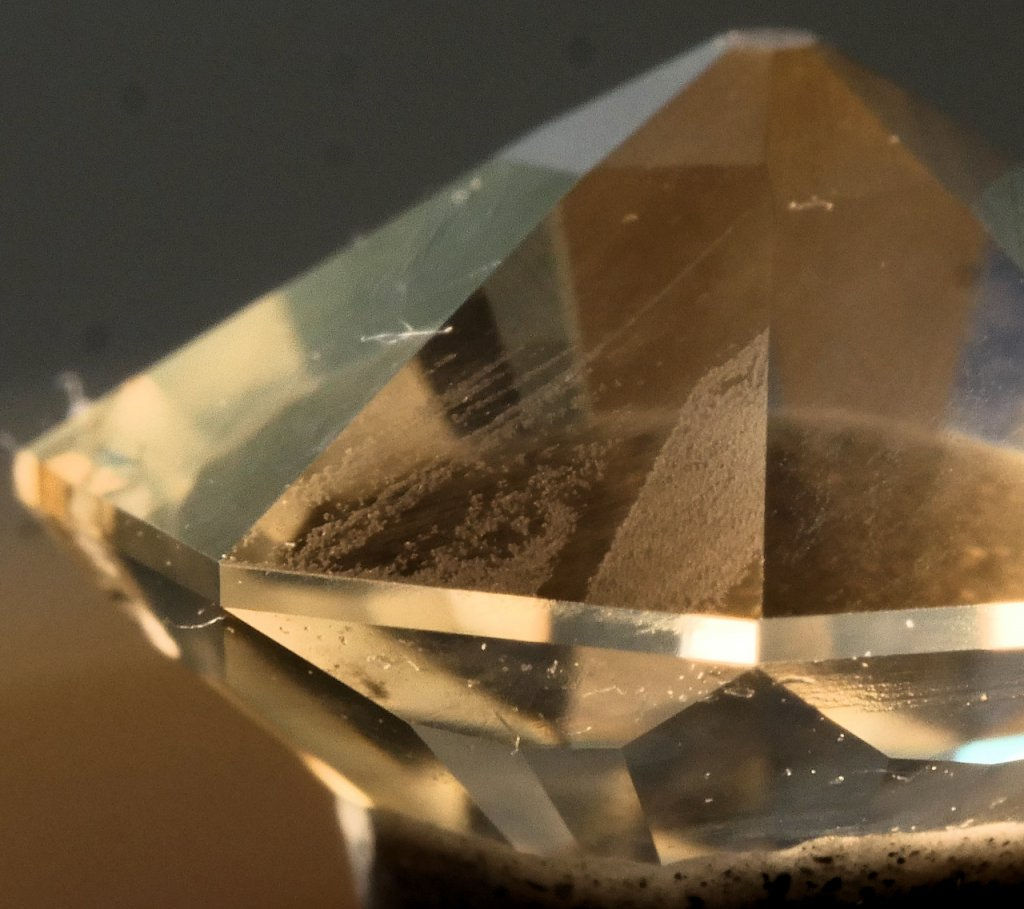

Found a nice little piece of Labradorite from our recent Hogarth Range collection and set about cutting. The pavilion went in beautifully and the crown was looking good until I started 8000 pre-polish.

7 out of the 8 break facets came up well but the 8th is sending me round the bend Think I have re-cut all 8 about 6 times but still this comes back to haunt me and I'm running out of ideas!

Think I have re-cut all 8 about 6 times but still this comes back to haunt me and I'm running out of ideas!

So far I've tried 8000 on copper (my go to) fast, slow, in fact about every speed available, then I tried 14,000 on typemetal, no different, even gone to 50k finish and it just scratches the hell out of this facet, then contaminates the lap and scratches the hell out of everything else. 8.(

Any ideas gang??? Or is this one for the bin!!

7 out of the 8 break facets came up well but the 8th is sending me round the bend

So far I've tried 8000 on copper (my go to) fast, slow, in fact about every speed available, then I tried 14,000 on typemetal, no different, even gone to 50k finish and it just scratches the hell out of this facet, then contaminates the lap and scratches the hell out of everything else. 8.(

Any ideas gang??? Or is this one for the bin!!