LORD

Jay

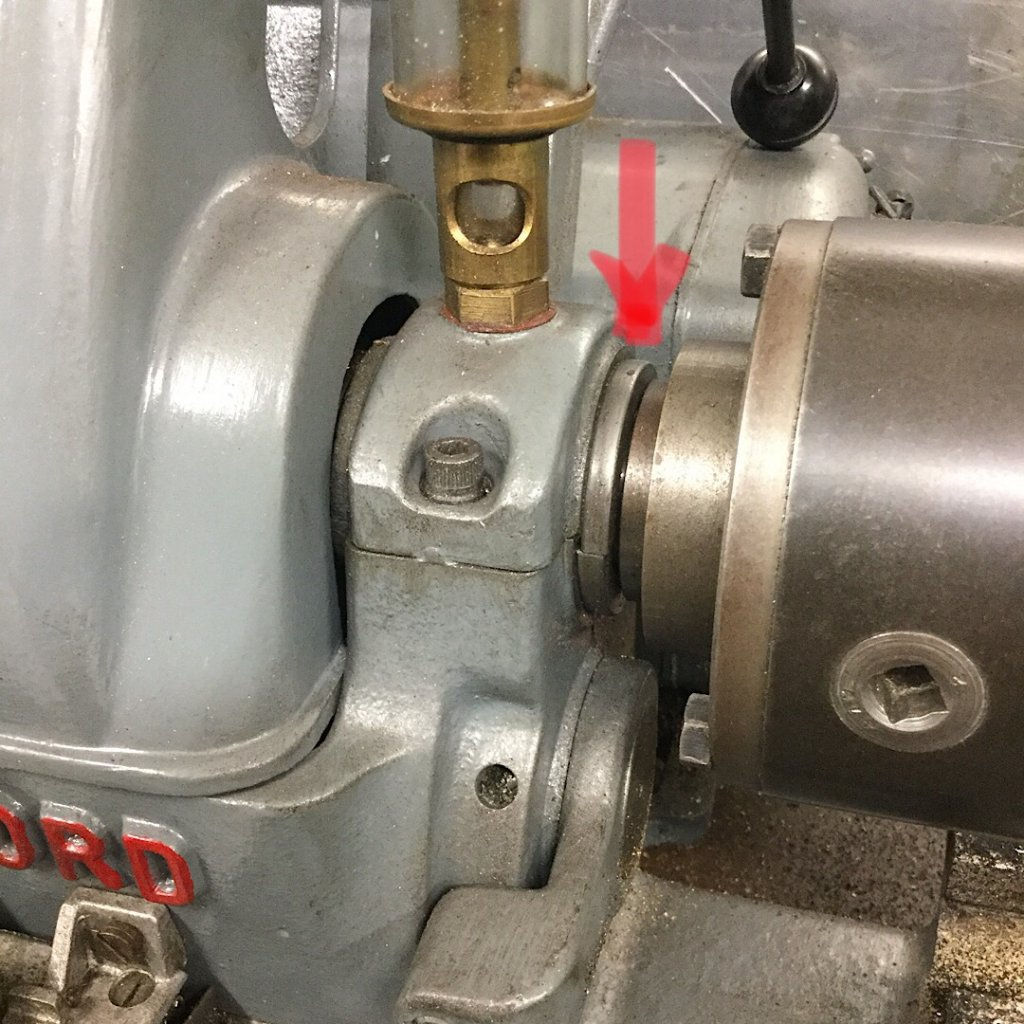

Someone out there will have the answer.

First i though it was an old section of pipe but it seems to short to be a usefull pipe.

Then i thought maby half a plain bearing due to the hole in the top (maby for grease) and the groove inside (maby a grease chanel )

Its solid copper / brass / bronze, something heavy thats golden colour when scratched and tarnished green.

First i though it was an old section of pipe but it seems to short to be a usefull pipe.

Then i thought maby half a plain bearing due to the hole in the top (maby for grease) and the groove inside (maby a grease chanel )

Its solid copper / brass / bronze, something heavy thats golden colour when scratched and tarnished green.