- Joined

- Jul 15, 2017

- Messages

- 42

- Reaction score

- 41

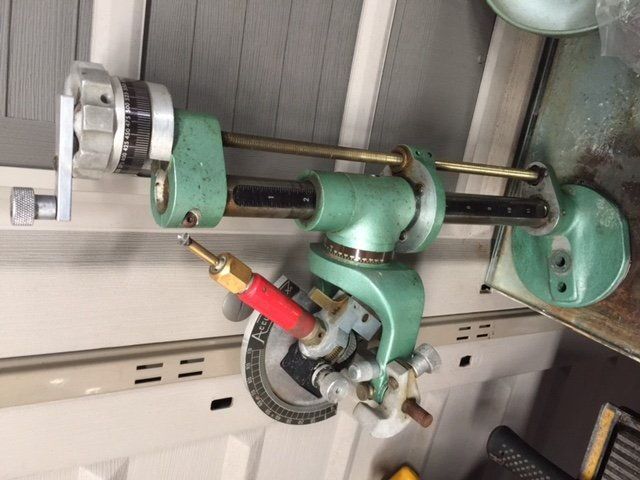

After listening to me complain never-endingly about my more than 60 year old Graves faceting machine, a friend lent me his old Prismatic. I don't know if any of you guys are familiar with this type of machine.

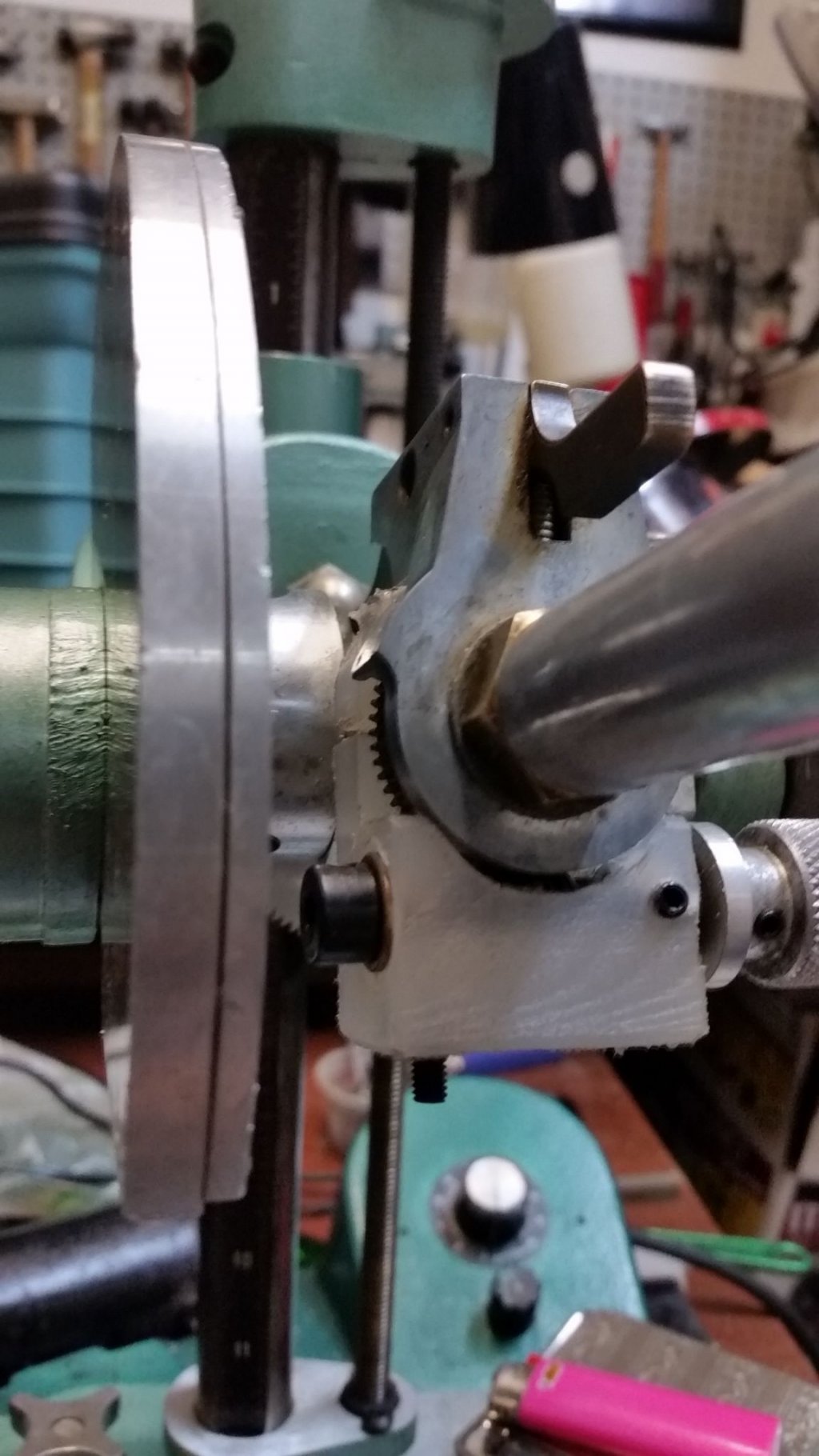

Someone, not him or me, overtightened a nut at the top of the quill which made the cheater impossible to turn. I backed it off, and when I did the crack opened up. Now the cheater works, but not too terribly well.

The bearings are shot; and it's not obvious about how to disassemble the head from the mast to replace them. It takes one hand to move the head and the other to hold on to the stone.

I'm thinking about making him an offer on this machine; the protractor is huge and it has a fine tune angle adjustment which is really nice, too. The bed is pretty level, it's variable speed and overall seems like it'd be a really good machine if it didn't have these problems.

I have an idea about what this machine would sell for if it were fully functional. I don't know what he paid for it; he got it at an auction and never used it. Do you think I'd be foolish to attempt these repairs myself? If not, how much would you knock off the value to do these sort of repairs? There's a fellow here in the states how does repairs and I've already sent him an email to see what he would charge.

Here's a picture of the machine and the cheater.

Debbie K

Someone, not him or me, overtightened a nut at the top of the quill which made the cheater impossible to turn. I backed it off, and when I did the crack opened up. Now the cheater works, but not too terribly well.

The bearings are shot; and it's not obvious about how to disassemble the head from the mast to replace them. It takes one hand to move the head and the other to hold on to the stone.

I'm thinking about making him an offer on this machine; the protractor is huge and it has a fine tune angle adjustment which is really nice, too. The bed is pretty level, it's variable speed and overall seems like it'd be a really good machine if it didn't have these problems.

I have an idea about what this machine would sell for if it were fully functional. I don't know what he paid for it; he got it at an auction and never used it. Do you think I'd be foolish to attempt these repairs myself? If not, how much would you knock off the value to do these sort of repairs? There's a fellow here in the states how does repairs and I've already sent him an email to see what he would charge.

Here's a picture of the machine and the cheater.

Debbie K