You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sneaky Gems.

- Thread starter SneakyCuttlefish

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

Hi Lefty. At the moment I am dopping both sides with wax. It takes a lot of finesse and patience to get it right without screwing up the orientation. I never thought of transferring with epoxy. That's a brilliant idea! How do you get the epoxy to release the stone afterwards? What brand epoxy do you use and how long do you have to wait for the glue to set?

- Joined

- May 1, 2014

- Messages

- 1,958

- Reaction score

- 2,530

SneakyCuttlefish said:Hi Lefty. At the moment I am dopping both sides with wax. It takes a lot of finesse and patience to get it right without screwing up the orientation. I never thought of transferring with epoxy. That's a brilliant idea! How do you get the epoxy to release the stone afterwards? What brand epoxy do you use and how long do you have to wait for the glue to set?

As long as the stone is not an overly heat-sensitive type, I simply hold the brass dop over a little tealight candle or spirit burner flame until the end I'm holding is starting to get a bit uncomfortably hot. At that point the epoxy will have softened and the stone can usually just be peeled straight off the dop with a twist and the remainder scraped off the stone with your thumbnail. If some clings stubbornly you can soak it for a few seconds in hot water and that usually softens it enough to be scraped off. Or you could soak it in acetone but I've rarely needed to.

Epoxy itself is actually a poor conductor of heat so it usually softens without transferring much heat through to the stone.

I use a two-part product called JB Kwik, available through Aussie Sapphire.

Right from the moment you start mixing, it has the consistency of toothpaste and so it tends to mostly stay where you put it, unlike Araldite which tends to be a bit runny. However, I've been told that regular Araldite works great as long as you mix equal parts of part A, part B and an equal measure of cornstarch (1 to 1 to 1 each). Apparently it thickens it and does not compromise strength. I haven't tried it myself though.

Epoxy is strong and you don't need much. It does take a while before I'm game to start cutting (the advantage of wax - virtually instant set), some people only wait 30 minutes but I usually give it at least 2 hours.

Most epoxies would be suitable I think as long as they were or could be made thick enough to be the consistency of a "liquidy paste".

Just make sure you don't grab the 250c heat-resistant kind coz I don't think a candleflame will avail you there

- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

Ever had one of those experience that just made you really appreciate the human race? Well last night was one of those for me. I attended a BBQ where my faceting mentor and my gem dealing mentor where both present. What an evening. Good wine, good food and plenty of gems. Much to my surprise and deepest appreciation, my faceting mentor came bearing gifts and some show and tell.

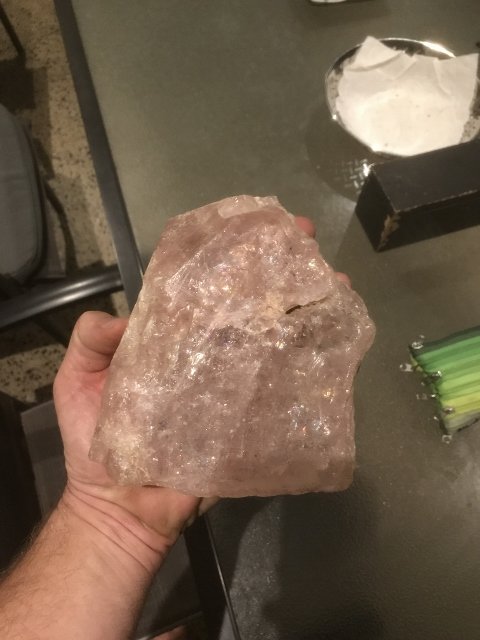

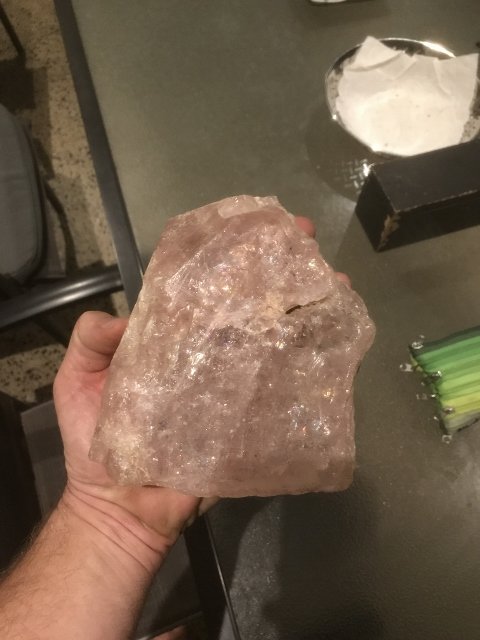

This is a single morganite crystal from Minas Gerais, Brazil. It has not been cut.The edges are all natural crystal faces. Sadly it is heavily included but the inclusions cause an explosion of rainbows inside it. He was very generous to give me smaller and much cleaner piece from another crystal. It has a few good sized cutters inside it but will require some careful examination to extract them.

He also gave me a big parcel of the most amazing smokys from the Swiss alps. The colour is gorgeous and the clarity is second to none.

And to top it all off he gave me an exquisite high quality Kruss refractometer to practice identification with. There is also a parcel of top quality amethyst from Pakistan that arrived in the mail yesterday.

My work is certainly cut out for me now. Goodbye social life, hello my pretties!!

This is a single morganite crystal from Minas Gerais, Brazil. It has not been cut.The edges are all natural crystal faces. Sadly it is heavily included but the inclusions cause an explosion of rainbows inside it. He was very generous to give me smaller and much cleaner piece from another crystal. It has a few good sized cutters inside it but will require some careful examination to extract them.

He also gave me a big parcel of the most amazing smokys from the Swiss alps. The colour is gorgeous and the clarity is second to none.

And to top it all off he gave me an exquisite high quality Kruss refractometer to practice identification with. There is also a parcel of top quality amethyst from Pakistan that arrived in the mail yesterday.

My work is certainly cut out for me now. Goodbye social life, hello my pretties!!

They are some big chunks of beryl, very nice indeed.

Looks like you have a few bit to keep you busy for a while.

Looks like you have a few bit to keep you busy for a while.

:Y:

- Joined

- May 10, 2015

- Messages

- 16

- Reaction score

- 0

Lefty said:SneakyCuttlefish said:I use 8" BATTS for 3000# pre-polish, 14000# polish, then straight to 100,000# on a 6"BATT. One thing with BATTS though, the factory finish is terrible so I take mine straight to our local engineer and have him re-surface it dead flat before I even use them. I just recently got a new 6" to try with 600# cutting compound but I wasn't happy with the results. I might have to grind a few peices of junk sapphire down to set the diamond in the alloy propperly.

Gearloose normally makes good laps - though I have to say that the first BATT I got couldn't be run at any speed because it was out of balance and I had to exchange it. No machining defects were visible, Rough2cut suggested it could be a metal density issue and Gearloose agreed this could well be the case. The new one was much better and I still use it.

Lefty, I've got one of Rough2cuts 800 sintered laps it's awesome. I'm coming straight of the 800 onto 100k on everything except sapphire

- Joined

- May 1, 2014

- Messages

- 1,958

- Reaction score

- 2,530

Hi Makky. I've been toying with the idea of splashing out on a sintered lap for a while, I definitely put in enough faceting hours to justify one. Just need to convince the minister of finance  or sell a sapphire or something.

or sell a sapphire or something.

Btw, did you ever get to that crossing on the Fitzroy river near Rockhampton (Riverslea) on any of your trips up here? It's days are numbered now, a weir is going to be built there and the spot will be flooded

Btw, did you ever get to that crossing on the Fitzroy river near Rockhampton (Riverslea) on any of your trips up here? It's days are numbered now, a weir is going to be built there and the spot will be flooded

- Joined

- May 10, 2015

- Messages

- 16

- Reaction score

- 0

I didn't mate, I think we ran out of time and gave other places preference after I think from memory a club may have gone there before we would have. The year after we went to Harts Range and last year like this year went nowhere due to commitments involving the Kids/School.robots etc etc

- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

I have been looking into a sintered lap as well. But I'm in the same boat as Lefty. Gotta put an application in with the Treasury.

- Joined

- May 10, 2015

- Messages

- 16

- Reaction score

- 0

The more I use mine the better it's getting  Best thing I've ever done in relation to faceting, the grief crappy chinese plated laps have caused me with scrathing I wish I did it earlier.

Best thing I've ever done in relation to faceting, the grief crappy chinese plated laps have caused me with scrathing I wish I did it earlier.

MakkyBrown said:The more I use mine the better it's gettingBest thing I've ever done in relation to faceting, the grief crappy chinese plated laps have caused me with scrathing I wish I did it earlier.

Ill second that. Worth every cent. It's a pleasure to use. It's smooth but efficient and fast. I know that sounds like an advert for a box of chocolates but it is a good lap. It feels like it's cutting not grinding.

- Joined

- May 10, 2015

- Messages

- 16

- Reaction score

- 0

Hey Mr Magoo, I'm guessing I know who you are. My new 5000cpr encoder is out for delivery tomorrow, less than a week from digikey and free postage  Just need one of the screens to arrive aswell.

Just need one of the screens to arrive aswell.

MakkyBrown said:Hey Mr Magoo, I'm guessing I know who you are. My new 5000cpr encoder is out for delivery tomorrow, less than a week from digikey and free postageJust need one of the screens to arrive aswell.

Ay? What? Who? :lol: Ha! Yes. I think you will like the 5000. Single ended? How much? You should try a 4D screen. Expensive but fun. Would love to know how the ones with claimed 0.01* accuracy do it.

- Joined

- May 10, 2015

- Messages

- 16

- Reaction score

- 0

Just under $70 delivered, yes single ended but I reckon it'd be pretty easy to add a line driver chip. I think the 0.01 accuracy on others is probably +/- a bit, and I have read the ultratec uses gearsMr Magoo said:MakkyBrown said:Hey Mr Magoo, I'm guessing I know who you are. My new 5000cpr encoder is out for delivery tomorrow, less than a week from digikey and free postageJust need one of the screens to arrive aswell.

Ay? What? Who? :lol: Ha! Yes. I think you will like the 5000. Single ended? How much? You should try a 4D screen. Expensive but fun. Would love to know how the ones with claimed 0.01* accuracy do it.

Those 4D screens do look nice, I just don't think the encoder needs it atm, screen size is the main thing don't really need the detail and just a serial connection.

Though a big touch screen with the angles/indexes from the .gem file display mighten be bad, it would clean up all the A4 sheets of paper I've got everywhere.

- Joined

- May 1, 2014

- Messages

- 1,958

- Reaction score

- 2,530

MakkyBrown said:The more I use mine the better it's gettingBest thing I've ever done in relation to faceting, the grief crappy chinese plated laps have caused me with scrathing I wish I did it earlier.

Yeah, I really should go for some high-quality laps with the amount of faceting I do. I have some old ones here that I inherited from granddad, made by the Melbourne diamond plating co, I guess they must be a good 40 years old. They appear to be plated rather than sintered but the plating layer appears deep and they seem to be made of steel. After all these years the coarser ones are still going strong but there weren't any of the fine ones. I do go through fine laps like 1200 and 3000.

I think all cutting laps need a bit of a break in period. The low-cost ones like Austcut can be used to cut without scratching depending on how you use them - sweep the lap back and forth while cutting the facet (to ensure even wear) until you get to the stage where it's making that tic-tic sound that lets you know it's almost done. Then cut for the last few seconds it takes to finish the facet in the outer portion of the lap and you will see a difference - there will be no scratches larger than the mesh size of the lap.

I can only theorize since I'm not an engineer but my suspicion is that the outer portion of the lap cuts cleaner because that portion is travelling a longer arc across the facet, hardly curving at all and abrading almost in a straight line on something that small. The area close to the arbor hole by contrast, is turning a very much tighter arc and the abrasive particles rip across the surface in a tight curve, often leaving deep scratches. That's the best explanation I can come up with but there is definitely a noticeable difference.

Of course, low-cost laps just don't last all that long if you do a lot of faceting and you're forever replacing them so sintered is a good investment.

- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

I have been using plated laps with a backing plate but my laps are rubbish. They don't sit flat on the backing plate so the dial indicator waves like a royals fanatic at a Buckingham parade. So annoying!!

This causes the facets to have a slight curve in them so they always need a bit of extra attention with a 3000# pre-polish BATT. I have tried everything. Even had the backing plate machined flat as a BATT. Still no difference.

As soon as I have a bit of spare coin I'll be swapping them all out with scintered laps and hard back laps.

This causes the facets to have a slight curve in them so they always need a bit of extra attention with a 3000# pre-polish BATT. I have tried everything. Even had the backing plate machined flat as a BATT. Still no difference.

As soon as I have a bit of spare coin I'll be swapping them all out with scintered laps and hard back laps.