- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

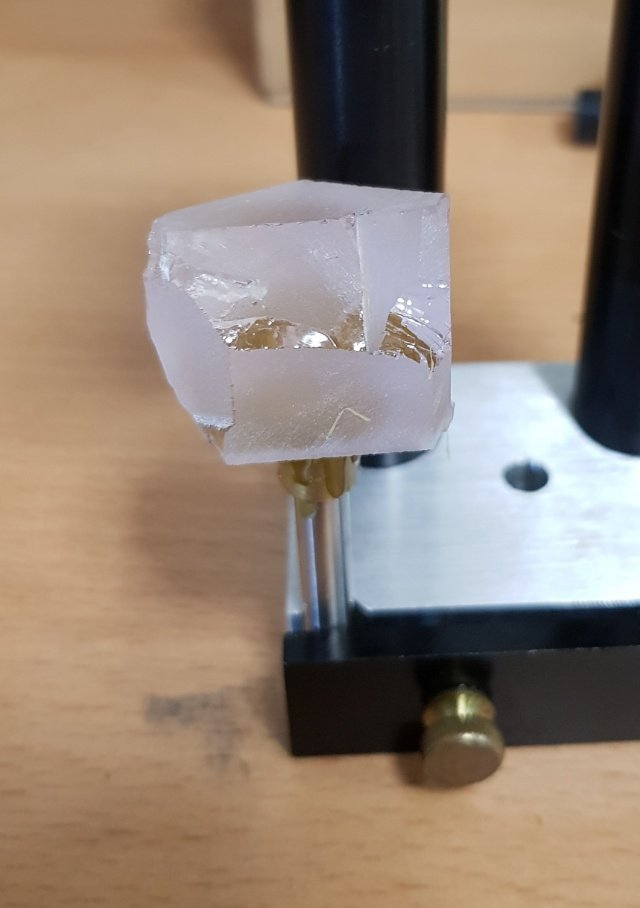

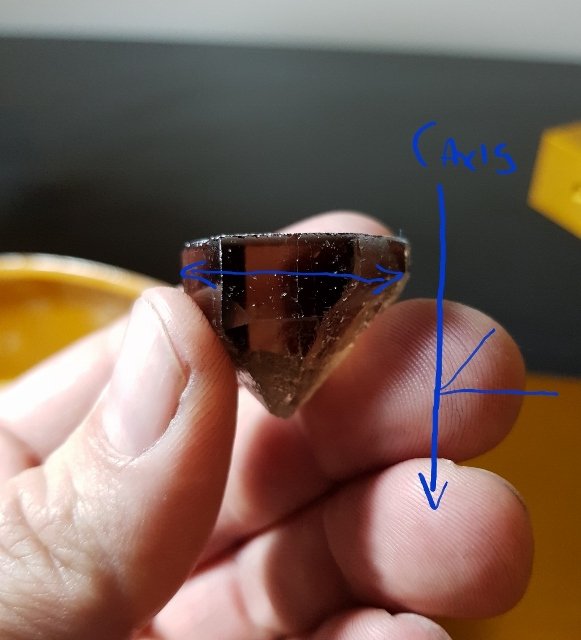

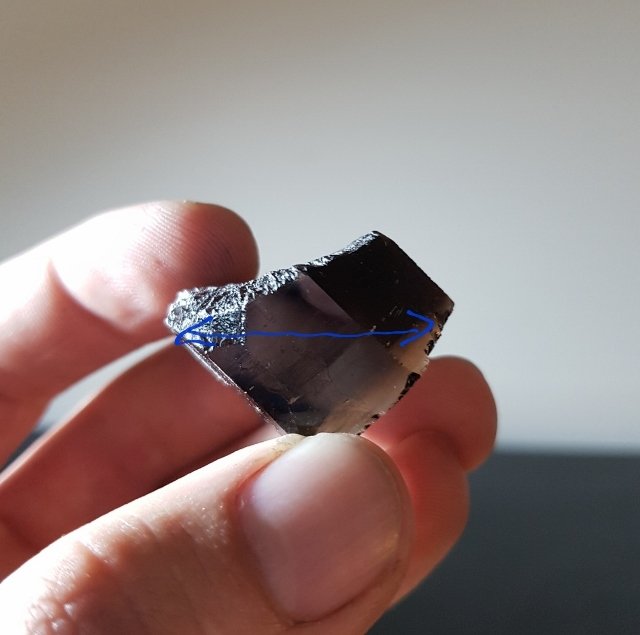

Latest project. A massive chunk of near flawless morganite. This is the color center for the big block i have been working on. It doesn't show through in the image but the pink is quite pronounced, very well saturated but light in tone. The color grade is the same as a good natural aquamarine.

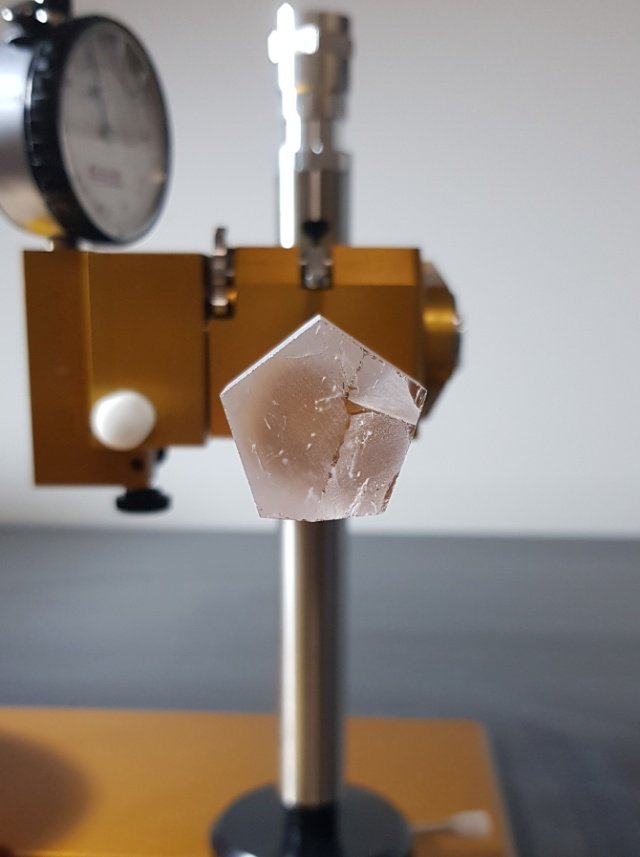

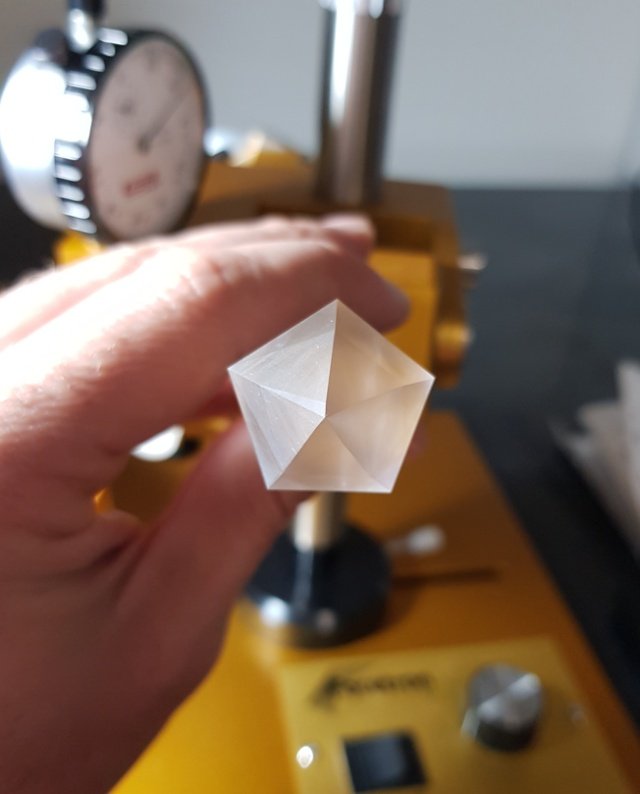

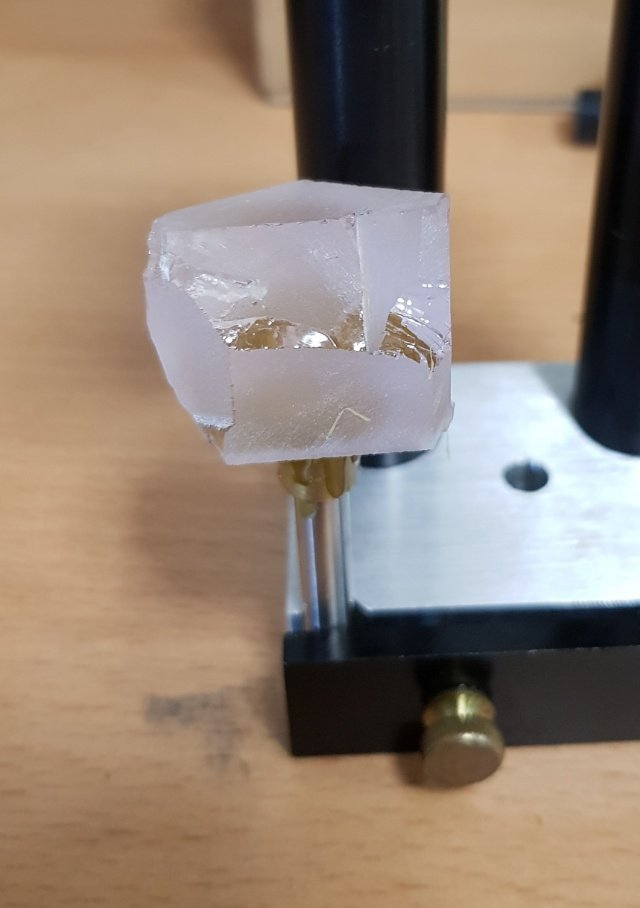

I have decided to do my latest custom pentagon design. Best fits the rough and it's a simple design. Big stone means big facets and big facets are hard work to polish and very time consuming. I could easily pack a gorgeous 100+ facet design into this piece but some times less is more.

I have decided to do my latest custom pentagon design. Best fits the rough and it's a simple design. Big stone means big facets and big facets are hard work to polish and very time consuming. I could easily pack a gorgeous 100+ facet design into this piece but some times less is more.