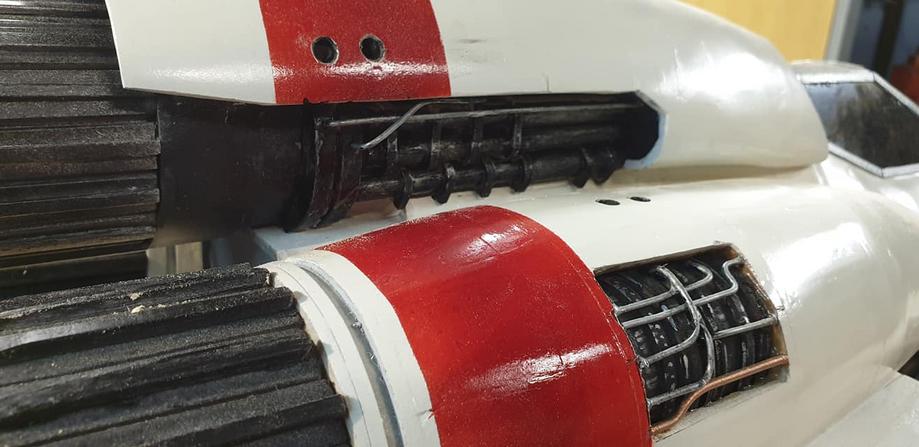

You can get in 20mm better into tight spots.... And it 'Feels' better in the hand....

LW....

LW....

goody2shoes said:Baz

Could a crevice tool be made with a leaf sping and cut it with a angle grinder?

I am trying to work out how I could make one for myself

Goody

Mackka said:Boys for me an extra 20 mm would not make any difference in performance, just sayin

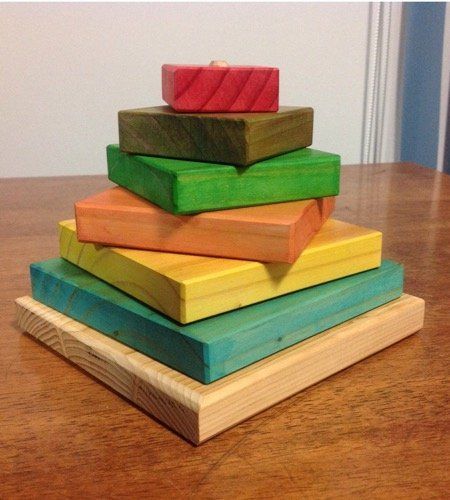

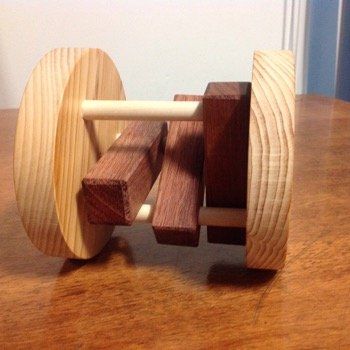

G0lddigg@ said:thats some mad skillz you have there sandbagger

Enter your email address to join: