- Joined

- Mar 10, 2016

- Messages

- 7,947

- Reaction score

- 16,016

Nice one Pa you are already the favourite :Y:  and trust me being favourite is hard work but a whole lot of fun

and trust me being favourite is hard work but a whole lot of fun  erfect: :heart: :beer:

erfect: :heart: :beer:

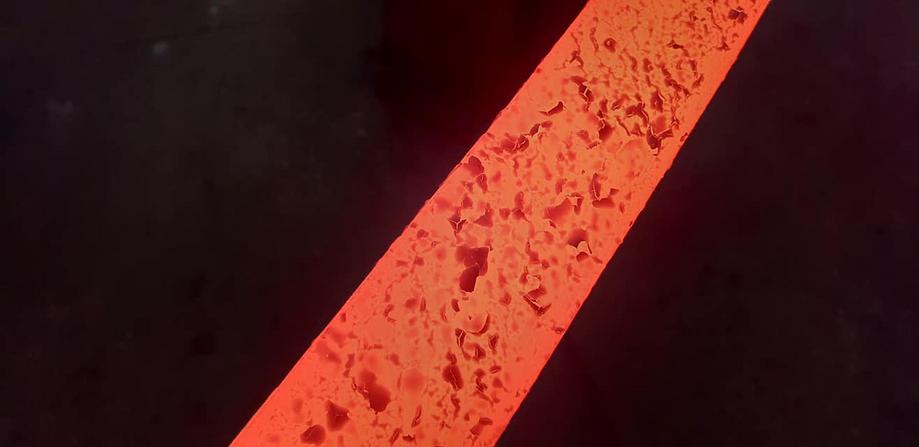

Sandbagger said:Terrifying. I've made a few billets from scratch before, under tuition from experienced operators, but today was my first time pattern welding, (modern Damascus) alone.

I have a twist billet of 16 layers that I made over a year ago now. Today I chopped it into into four lengths, re-stacked, (64 layers now) and squashed out into a dimension precise billet to stock-remove one big knife and it's guard, without further disrupting the pattern by forging the shape. I'm hoping to expose certain patterns as I grind the bevel geometries in.

Taking my time with this one. For me personally, it's a big investment in my personal development as a knife maker.

More to follow as I can.

The video shows me doing the first power hammer set after the initial press under a hydraulic press, subsequent heats and hammers were used to draw out the bar and size it width and thickness.

https://i.imgur.com/SfTsbKn.jpg?1

Trash said:Insanely great Sandbagger

Has NASA offered you a job .....?

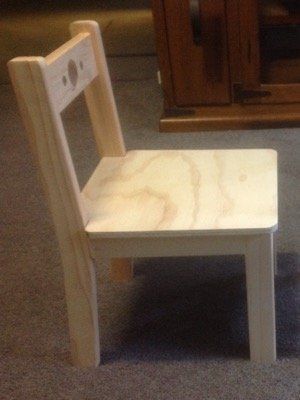

Manpa said:Couple of chairs for the grandkids, yet to do table. To finish in clear Estapol.

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747822_image.jpg

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747846_image.jpg

Gpx5000 said:Manpa said:Couple of chairs for the grandkids, yet to do table. To finish in clear Estapol.

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747822_image.jpg

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747846_image.jpg

Makes a change from knives :Y:

Sandbagger said:Gpx5000 said:Manpa said:Couple of chairs for the grandkids, yet to do table. To finish in clear Estapol.

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747822_image.jpg

https://www.prospectingaustralia.com/forum/img/member-images/11747/1567747846_image.jpg

Makes a change from knives :Y:

Ok ok...I'll stop posting.

Enter your email address to join: